Abstract

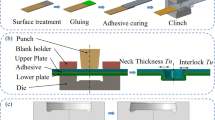

The purpose of this study is to investigate the effects of process parameters on the joint characteristics of advanced high-strength steel DP780 and Al5052 alloy sheet in mechanical clinching process. The defects in the clinching joint, such as necking of the upper sheet, cracks in the lower sheet, and no interlocking, occur because of the different ductility between advanced high-strength steel and aluminum alloy. In this study, the effect of the process parameters of the clinching process on the joinability of advanced high-strength steel with Al5052 alloy was investigated using finite element (FE) analysis. From the result, the die radius, die depth, and die groove shape were mainly affected by the joinability of advanced high-strength steel with Al5052 alloy. H-type tension test was performed under the same condition as the FE analysis. In addition, the joint strength was determined by interlocking length as well as neck thickness.

Similar content being viewed by others

References

M. Oudjene and L. Ben-Ayed, On the parametric study of clinch joining of metallic sheets using the Taquchi method, Engineering Structures 30 (2008) 1782–1788.

A.A. de Paula et al., Finite element simulations of the clinch joining of metallic sheets, J. of Mat. Proc. Tech. 182 (2007) 352–357.

J.P. Varis, Economics of clinched joint compared to riveted joint and example of applying calculations to a volume product, J. of Mat. Proc. Tech. 172 (1992) 130–138.

K. Mori et al., Plastic joining of aluminium alloy and high strength steel sheets by mechanical clinching, Steel Research International 79(Metal forming) (2008) 649–656.

Author information

Authors and Affiliations

Corresponding author

Additional information

Byung-Min Kim received his B.S. degree (1979), M.S. (1984) and Ph.D. (1987) from Pusan National University. He is currently a Professor at the School of Mechanical Engineering at Pusan National University, and currently serving as a Director in PNU-IFAM Joint Research Center. His major area is metal forming process and hybrid joining technology.

Rights and permissions

About this article

Cite this article

Lee, CJ., Kim, JY., Lee, SK. et al. Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J Mech Sci Technol 24, 123–126 (2010). https://doi.org/10.1007/s12206-009-1118-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-009-1118-5