Abstract

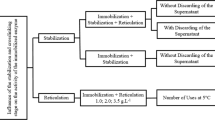

In the present study, Enterobacter aerogenes KCTC2190 was isolated from soil around a cattle shed area, which was capable of producing intracellular β-galactosidase. Partially purified β-galactosidase was immobilized by entrapment method in agar-agar gel matrix. Agar-agar entrapped beads were prepared by drop** the enzyme-agar solution to ice-cooled toluene-chloroform ((3:1 (v/v)). 45.88±0.11% activity of partially purified β-galactosidase was retained after immobilization (bead shape). Maximum immobilization yield was observed in the presence of 2.5% agar-agar concentration. After immobilization, optimum temperature required for the enzyme-substrate reaction was shifted from 50 to 60 °C and the optimum reaction time was shifted from 15 to 25 min. The optimum pH for both free and immobilized β-galactosidase was pH 7. Free enzyme showed lower activation energy in comparison with the immobilized one. For free as well as immobilized β-galactosidase thermal deactivation, rate constant (kd) increased with increasing temperature while the values of decimal reduction time (D-values) and half-lives (t1/2) decreased. Immobilization process increased the t1/2 and D-values of β-galactosidase while it decreased the kd. Thermostability of immobilized β-galactosidase was higher as they showed higher enthalpy (ΔΗ0) and Gibb’s free energy (ΔG0)value than those of the free β-galactosidase. The negative entropy (ΔS0) of free and immobilized β-galactosidase established that both were in a more ordered state within the temperature range (50 to 70 °C) studied. Immobilized β-galactosidase was able to retain 51.65±1.61% of its initial activity after 7 batches of enzyme-substrate reaction. Immobilized β-galactosidase showed 78.09±3.69% of its initial activity even after 40 days of storage at 4 °C.

Similar content being viewed by others

References

**, L., Li, Y., Ren, X. H., & Lee, J. H. (2015). Immobilization of lactase onto various polymer nanofibers for enzyme stabilization and recycling. Journal of Microbiology and Biotechnology, 25(8), 1291–1298. https://doi.org/10.4014/jmb.1501.01012.

Martarello, R. D. A., Cunha, L., Cardoso, S. L., de Freitas, M. M., Silveira, D., Fonseca-Bazzo, Y. M., Homem-de-Mello, M., Filho, E. X. F., & Magalhães, P. O. (2019). Optimization and partial purification of beta-galactosidase production by Aspergillus niger isolated from Brazilian soils using soybean residue. AMB Express, 9(1), 81. https://doi.org/10.1186/s13568-019-0805-6.

Xu, X., Fan, X., Fan, C., Qin, X., Liu, B., Nie, C., Sun, N., Yao, Q., Zhang, Y., & Zhang, W. (2019). Production optimization of an active-galactosidase of Bifidobacterium animalis in heterologous expression systems. BioMed Research International, 2019, 1–10. https://doi.org/10.1155/2019/8010635.

Oluwaniyi, T. T., Omafuvbe, B. O., & Agboola, F. K. (2016) Purification and characterization of β-galactosidase from Kluveromyces lactis isolated from a yoghurt waste site. Research & Reviews: Journal of Microbiology and Biotechnology, 5, 52–57.

Venkateswarulu, T. C., Peele, K. A., Krupanidhi, S., Reddy, K. P. N., Indira, M., Rao, A. R., Kumar, R. B., & Prabhakar, K. V. (2020). Biochemical and molecular characterization of lactase producing bacterium isolated from dairy effluent. Journal of King Saud University-Science, 32(2), 1581–1585. https://doi.org/10.1016/j.jksus.2019.12.014.

Niu, D., Tian, X., Mchunu, N. P., Jia, C., Singh, S., Liu, X., Prior, B. A., & Lu, F. (2017). Biochemical characterization of three Aspergillus niger β-galactosidases. Electronic Journal of Biotechnology, 27, 37–43. https://doi.org/10.1016/j.ejbt.2017.03.001.

Gomaa, E. Z. (2018). β-galactosidase from Lactobacillus delbrueckii and Lactobacillus reuteri: optimization, characterization and formation of galactooligosaccharides. Indian Journal of Biotechnology, 17, 407–415.

Venkateswarulu, T. C., Vidya Prabhakar, K., & Bharath Kumar, R. (2017). Optimization of nutritional components of medium by response surface methodology for enhanced production of lactase. 3 Biotechnol, 7, 1–9. https://doi.org/10.1007/s13205-017-0805-7.

Alikkunju, A. P., Sainjan, N., Silvester, R., Joseph, A., Rahiman, M., Antony, A. C., Kumaran, R. C., & Hatha, M. (2016). Screening and characterization of cold-active β -galactosidase producing psychotrophic Enterobacter ludwigii from the sediments of Arctic Fjord. Applied Biochemistry and Biotechnology. https://doi.org/10.1007/s12010-016-2111-y.

Ghatak, A., Guha, A. K., & Ray, L. (2013). Immobilization of β -galactosidase from Enterobacter cloacae : characterization and its use in the continuous production of low lactose milk. Indian Journal of Biotechnology, 12, 523–530.

Maheswari, N. U., & Priyadarshini, S. I. (2014). Effect of different immobilization techniques on α- amylase. Journal of Chemical and Pharmaceutical Research, 6(5), 768–774.

Datta, S., Christena, L. R., & Rajaram, Y. R. S. (2013). Enzyme immobilization: an overview on techniques and support materials. 3. Biotech, 3(1), 1–9. https://doi.org/10.1007/s13205-012-0071-7.

Mahajan, R., Gupta, V. K., & Sharma, J. (2010). Comparison and suitability of gel matrix for entrap** higher content of enzymes for commercial applications. Indian Journal of Pharmaceutical Sciences, 72(2), 223. https://doi.org/10.4103/0250-474X.65010.

Mohamad, N. R., Marzuki, N. H. C., Buang, N. A., Huyop, F., & Wahab, R. A. (2015). An overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnology & Biotechnological Equipment, 29(2), 205–220. https://doi.org/10.1080/13102818.2015.1008192.

Pervez, S., Nawaz, M. A., Jamal, M., Jan, T., Maqbool, F., Shah, I., Aman, A., & Qader, S. A. U. (2019). Improvement of catalytic properties of starch hydrolyzing fungal amyloglucosidase: utilization of agar-agar as an organic matrix for immobilization. Carbohydrate Research, 486, 107860. https://doi.org/10.1016/j.carres.2019.107860.

Sattar, H., Aman, A., & Qader, S. A. U. (2018). Agar-agar immobilization: An alternative approach for the entrapment of protease to improve the catalytic efficiency, thermal stability and recycling efficiency. International Journal of Biological Macromolecules, 111, 917–922. https://doi.org/10.1016/j.ijbiomac.2018.01.105.

Bustamante-Vargas, C. E., Junges, A., Venquiaruto, L. D., Oro, C. E. D., Julio-Orozco, D. J., Zabot, G. L., Tres, M. V., Paroul, N., Backes, G. T., & Dallago, R. M. (2019). Thermal inactivation kinetics and thermodynamic properties of immobilised Aspergillus niger pectinase in rigid polyurethane foam. International Food Research Journal, 26(5), 1535–1545.

Nguyen, T. H., Splechtna, B., Steinböck, M., Kneifel, W., Lettner, H. P., Kulbe, K. D., & Haltrich, D. (2006). Purification and characterization of two novel β-galactosidases from Lactobacillus reuteri. Journal of Agricultural and Food Chemistry, 54(14), 4989–4998. https://doi.org/10.1021/jf053126u.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., & Randal, R. L. (1951). Protein measurement with Folin phenol reagent. The Journal of Biological Chemistry, 193(1), 265–275.

Holt, J. G., Krieg, N. R., Peter, H. A. S., & Bergy, D. H. (1994). Bergy’s manual of determinative Bacteriology (9th ed.). Philadelphia: Lippincott Williams & Wilkins.

Lee, J. Y., Kwak, M. S., Roh, J. B., Kim, K., & Sung, M. H. (2017). Microbial β-galactosidase of Pediococcus pentosaceus ID-7: Isolation, cloning, and molecular characterization. Journal of Microbiology and Biotechnology, 27(3), 598–609. https://doi.org/10.4014/jmb.1611.11015.

Sumathy, R., Vijayalakshmi, M., & Deecaraman, M. (2012). Study on β-galactosidase of Lactobacillus SP from milk products and its applications. International Journal of Applied Biology and Pharmaceutical Technology, 3(4), 138–148.

Konozy, E. H. E. (2016). Isolation, purification and characterization of a thermostable β-galactosidase isoform from Erythrina indica seeds. Global Advanced Research Journal of Agricultural Science, 5(6), 175–182.

Sen, S., Ray, L., & Chattopadhyay, P. (2012). Production, purification, immobilization, and characterization of a thermostable β-galactosidase from Aspergillus alliaceus. Applied Biochemistry and Biotechnology, 167(7), 1938–1953. https://doi.org/10.1007/s12010-012-9732-6.

Rehman, H. U., Aman, A., Zoha, R. R., & Qader, S. A. U. (2014). Immobilization of pectin degrading enzyme from Bacillus licheniformis KIBGE IB-21 using agar-agar as a support. Carbohydrate Polymers, 102, 622–626. https://doi.org/10.1016/j.carbpol.2013.11.073.

Wahab, W. A. A., Karam, E. A., Hassan, M. E., Kansoh, A. L., Esawy, M. A., & Awad, G. E. (2018). Optimization of pectinase immobilization on grafted alginate-agar gel beads by 24 full factorial CCD and thermodynamic profiling for evaluating of operational covalent immobilization. International Journal of Biological Macromolecules, 113, 159–170. https://doi.org/10.1016/j.ijbiomac.2018.02.086.

Pal, A., Lobo, M., & Khanum, F. (2013). Extraction , purification and thermodynamic characterization of almond ( Amygdalus communis ) b -galactosidase for the preparation of delactosed milk. Food Technology and Biotechnology, 51(1), 53–61.

Maity, M., Sanyal, S., Bhowal, J., & Bhattacharyya, D. K. (2013). Studies on isolation and characterization of lactase produced from soil bacteria. Research Journal of Recent Sciences, 2(8), 92–94.

Ghatak, A., Guha, A. K., & Ray, L. (2010). β - D -galactosidase from Enterobacter cloacae : production and some physicochemical properties. Applied Biochemistry and Biotechnology, 162(6), 1678–1688. https://doi.org/10.1007/s12010-010-8949-5.

Mozumder, N. H. M. R., Akhtaruzzaman, M., Bakr, M. A., & Zohra, F. T. (2012). Study on isolation and partial purification of lactase (β-galactosidase) enzyme from Lactobacillus bacteria isolated from yogurt. Journal of Scientific Research, 4(1), 239–239.

Kalita, T., Sangma, S. D., Bez, G., & Ambasht, P. K. (2020). Immobilization of acid phosphatase in agar-agar and gelatin: comparative characterization. Journal of Scientific Research, 64(2), 192–200. https://doi.org/10.37398/JSR.2020.640227.

Singh, R. S., Saini, G. K., & Kennedy, J. F. (2010). Covalent immobilization and thermodynamic characterization of pullulanase for the hydrolysis of pullulan in batch system. Carbohydrate Polymers, 81(2), 252–259. https://doi.org/10.1016/j.carbpol.2010.02.027.

Selvarajan, E., & Mohanasrinivasan, V. (2015). Kinetic studies on exploring lactose hydrolysis potential of β galactosidase extracted from Lactobacillus plantarum HF571129. Journal of Food Science and Technology, 52(10), 6206–6217. https://doi.org/10.1007/s13197-015-1729-z.

Ahmed, S. A., Saleh, S. A., Abdel-Hameed, S. A., & Fayad, A. M. (2019). Catalytic, kinetic and thermodynamic properties of free and immobilized caseinase on mica glass-ceramics. Heliyon, 5(5), e01674. https://doi.org/10.1016/j.heliyon.2019.e01674.

Pal, A., & Khanum, F. (2012). Covalent immobilization of xylanase on the surface of alginate-glutaraldehyde beads decreases the ‘catalytic efficiency’but provides ‘low temperature stabilization’effect. Journal of Biochemical Technology, 3(5), 409–413.

Pradhan, S., Gothwal, R. K., Mohan, M. K., & Ghosh, P. Evaluating bacterial cell immobilization of Brevibacillus formosus BISR-1 and Paenibacillus sp. BISR-047 with different matrices. International Journal of Engineering Research & Technology, 8(6), 1358–1363.

Acknowledgements

The authors are grateful to the School of Community Science and Technology, Indian Institute of Engineering Science and Technology, Shibpur, India, for giving facilities to pursue the research work. Authors are thankful to the Indian Council of Medical Research, New Delhi, India, for providing Senior Research Fellowship to carry out the study.

Code Availability

Not applicable

Author information

Authors and Affiliations

Contributions

Experimental design, data collection, data analysis, and preparation of manuscript draft were carried out by Manisha Maity. Research conceptualization, data interpretation, and preparation of manuscript draft were performed by Aparupa Bhattacharyya. Research conceptualization and preparation of manuscript draft were carried out by Jayati Bhowal. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable

Consent to Participate

Not applicable

Consent for Publication

Not applicable

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maity, M., Bhattacharyya, A. & Bhowal, J. Production and immobilization of β-galactosidase isolated from Enterobacter aerogenes KCTC2190 by entrapment method using agar-agar organic matrix. Appl Biochem Biotechnol 193, 2198–2224 (2021). https://doi.org/10.1007/s12010-021-03534-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-021-03534-8