Abstract

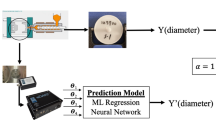

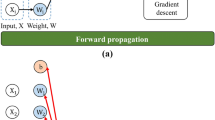

Injection molding is classified as one of the economical manufacturing processes for high volume production of plastic parts. However, it is a complex process, as there are many factors that could lead to process variations and thus the quality issues of final products. One common quality issue is the presence of shrinkage and its associated warpage. Part shrinkage is largely affected by molding conditions, as well as mold design and material properties. The main objective of this paper is to predict the shrinkage of injection molded parts under different processing parameters. The second objective is to facilitate the setup of injection molding machine and reduce the need for trial and error. To meet these objectives, an artificial neural network (ANN) model was presented in this study, to predict the part shrinkage from the optimal molding parameters. Molding parameters studied include injection speed, holding time, and cooling time. A Taguchi-based experimental study was conducted, to identify the optimal molding condition which can lead to the minimum shrinkages in the length and width directions. A L27 (33) orthogonal array (OA) was applied in the Taguchi experimental design, with three controllable factors and one non-controllable noise factor. The feedforward neural network model, trained in back propagation, was validated by comparing the predicted shrinkage with the actual shrinkage obtained from Taguchi-based experimental results. It demonstrates that the ANN model has a high prediction accuracy, and can be used as a quality control tool for part shrinkage in injection molding.

Similar content being viewed by others

References

Han, S., Wang, K.K.: Shrinkage prediction for slowly-crystallizing thermoplastic polymers in injection molding. Int. Polym. Proc. 12(3), 228–237 (1997)

Jansen, K.M.B., Van Dijk, D.J., Husselman, M.H.: Effect of processing conditions on shrinkage in injection molding. Polym. Eng. Sci. 38(5), 838–846 (1998)

Choi, D.S., Im, Y.T.: Prediction of shrinkage and warpage in consideration of residual stress in integrated simulation of injection molding. Compos. Struct. 47(1), 655–665 (1999)

Lucyshyn, T., Knapp, G., Kipperer, M., Holzer, C.: Determination of the transition temperature at different cooling rates and its influence on prediction of shrinkage and warpage in injection molding simulation. J. Appl. Polym. Sci. 123(2), 1162–1168 (2012)

Pomerleau, J., Sanschagrin, B.: Injection molding shrinkage of PP: experimental progress. Polym. Eng. Sci. 46(9), 1275–1283 (2006)

Shen, C., Wang, L., Li, Q.: Optimization of injection molding process parameters using combination of artificial neural network and genetic algorithm method. J. Mater. Process. Technol. 183(2), 412–418 (2007)

Lee, S.C., Youn, J.R.: Shrinkage analysis of molded parts using neural network. J. Reinf. Plast. Compos. 18(2), 186–195 (1999)

Liao, S.J., Hsieh, W.H., Wang, J.T., Su, Y.C.: Shrinkage and warpage prediction of injection-molded thin-wall parts using artificial neural networks. Polym. Eng. Sci. 44(11), 2029–2040 (2004)

Wang, R., Zeng, J., Feng, X., **a, Y.: Evaluation of effect of plastic injection molding process parameters on shrinkage based on neural network simulation. J. Macromol. Sci. Part B 52(1), 206–221 (2013)

Altan, M.: Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods. Mater. Des. 31(1), 599–604 (2010)

Tsai, K.M., Luo, H.J.: An inverse model for injection molding of optical lens using artificial neural network coupled with genetic algorithm. J. Intell. Manuf. 28(2), 473–487 (2017)

Gong, G., Chen, J.C., Guo, G.: Enhancing tensile strength of injection molded fiber reinforced composites using the Taguchi-based six sigma approach. Int. J. Adv. Manuf. Technol. 91(9), 3385–3393 (2017)

Chang, T.C., Faison, E.: Shrinkage behavior and optimization of injection molded parts studied by the Taguchi method. Polym. Eng. Sci. 41(5), 703–710 (2001)

Demuth, H. and Beale, M., 1992. Neural Network Toolbox. For Use with MATLAB. The MathWorks Inc, 2000

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. However, the corresponding author appreciates the Caterpillar Fellowship supported from Bradley University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors of this paper do not have any conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

About this article

Cite this article

Abdul, R., Guo, G., Chen, J.C. et al. Shrinkage prediction of injection molded high density polyethylene parts with taguchi/artificial neural network hybrid experimental design. Int J Interact Des Manuf 14, 345–357 (2020). https://doi.org/10.1007/s12008-019-00593-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-019-00593-4