Abstract

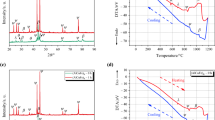

To address the gap in material design strategies for structural components in molten salt-powered technologies, the current work aimed to identify key parameters governing corrosion induced degradation of materials during exposures in molten halide salts. The applicability of the data on dissolution rates of pure metals (e.g., Cr) in a given molten salt to enable predictions of corrosion behavior of multicomponent binary and ternary Fe-based model and Ni-based commercial alloys isothermally exposed in the purified KCl-Mg\({{\hbox {Cl}}_2}\) in quartz capsules at 700 and 800°C was evaluated. The influence of alloy chemistry on initial dissolution rates and the consequent impact on the time-dependent corrosion induced microstructural evolution in the alloy subsurface was predicted with a coupled thermodynamic-kinetic model. The model was well able to predict the Cr depletion in all investigated alloys demonstrating the ability of the proposed approach to enable a unique design strategy for structural materials in molten salts.

Similar content being viewed by others

References

C. Le Brun, J. Nucl. Mater. 360(1), 1 (2007). https://doi.org/10.1016/j.jnucmat.2006.08.017

G. Locatelli, M. Mancini, N. Todeschini, Energy Policy 61, 1503 (2013). https://doi.org/10.1016/j.enpol.2013.06.101

J. Serp, M. Allibert, O. Benes, S. Delpech, O. Feynberg, V. Ghetta, D. Heuer, D. Holcomb, V. Ignatiev, J.L. Kloosterman, L. Luzzi, E. Merle-Lucotte, J. Uhlir, R. Yoshioka, Z.M. Dai, Progr. Nucl. Energy 77, 308 (2014). https://doi.org/10.1016/j.pnucene.2014.02.014

A. Tonti, C. Renault, M. Sperandio, C. DelleSite, G. Baylac, F. Carre, Proc. Asme Pressure Vessels Pi** Conf. 1, 657 (2009)

M. Mehos, C. Turchi, J. Vidal, M. Wagner, Z. Ma, C. Ho, W. Kolb, C. Andraka, A. Kruizenga, Concentrating Solar Power Gen3 Demonstration Roadmap, Report NREL/TP-5500-67464, NREL, (2017)

C.W. Forsberg, Int. J. Hyd. Energy 28(10), 1073 (2003)

P.N. Haubenreich, Nucl. Eng. Int. 14(155), 325 (1969)

M.W. Rosenthal, P.R. Kasten, R.B. Briggs, Nucl. Appl. Technol. 8(2), 107 (1970). https://doi.org/10.13182/Nt70-A28619

W. Manly, G. J. Adamson, J. Coobs, J. DeVan, D. Douglas, E. Hoffman, P. Patriarca, Aircraft Reactor Experiment–Metallurgical Aspects, Report ORNL-2349 United States 10.2172/4227617 NTIS ORNL English, ; Oak Ridge National Lab., Tenn., https://www.osti.gov/servlets/purl/4227617, other Information: Decl. Oct. 9, 1959. Orig. Receipt Date: 31-DEC-60, (1958)

J.C. Gomez-Vidal, R. Tirawat, Solar Energy Mater. Solar Cells 157, 234 (2016). https://doi.org/10.1016/j.solmat.2016.05.052

G.Q. Zheng, K. Sridharan, Jom 70(8), 1535 (2018). https://doi.org/10.1007/s11837-018-2981-2

H. Sun, J.Q. Wang, Z.J. Li, P. Zhang, X.Z. Su, Solar Energy 171, 320 (2018). https://doi.org/10.1016/j.solener.2018.06.094

B.A. Pint, J.W. McMurray, A.W. Willoughby, J.M. Kurley, S.R. Pearson, M.J. Lance, D.N. Leonard, H.M. Meyer, J. Jun, S.S. Raiman, R.T. Mayescirc, Mater. Corros. 70(8), 1439 (2019). https://doi.org/10.1002/maco.201810638

J. H. De Van Thesis ORNL/TM-2021/1, (1969)

I.N. Ozeryanaya, Metal Sci. Heat Treat. 27(3), 184 (1985). https://doi.org/10.1007/bf00699649

A. Kruizenga, Corrosion Mechanisms in Chloride and Carbonate Salts, Report SAND2012-7594, Sandia National Laboratories, (2012)

W. Ding, H. Shi, Y. **u, A. Bonk, A. Weisenburger, A. Jianu, T. Bauer, Solar Energy Mater. Solar Cells 184, 22 (2018). https://doi.org/10.1016/j.solmat.2018.04.025

R. Pillai, S.S. Raiman, B.A. Pint, J. Nucl. Mater. (2021). https://doi.org/10.1016/j.jnucmat.2020.152755

H.S. Cho, J.W. Van Zee, S. Shimpalee, B.A. Tavakoli, J.W. Weidner, B.L. Garcia-Diaz, M.J. Martinez-Rodriguez, L. Olson, J. Gray, Corrosion 72(6), 742 (2016). https://doi.org/10.5006/1865

B.A.T. Mehrabadi, J.W. Weidner, B. Garcia-Diaz, M. Martinez-Rodriguez, L. Olson, S. Shimpalee, J. Electrochem. Soc. 163(14), C830 (2016). https://doi.org/10.1149/2.0411614jes

J. H. DeVan, R. B. Evans, III, Corrosion Behavior of Reactor Materials in Fluoride Salt Mixtures, Report ORNL-TM-328, https://doi.org/10.2172/4774669, (1962)

H.E. McCoy, R.L. Beatty, W.H. Cook, R.E. Gehlbach, C.R. Kennedy, J.W. Koger, A.P. Litman, C.E. Sessions, J.R. Weir, Nucl. Appl. Technol. 8(2), 156 (1970). https://doi.org/10.13182/Nt70-A28622

G. Zheng, L. He, D. Carpenter, K. Sridharan, J. Nucl. Mater. 482, 147 (2016). https://doi.org/10.1016/j.jnucmat.2016.10.023

C. Falconer, W.H. Doniger, L. Bailly-Salins, E. Buxton, M. Elbakhshwan, K. Sridharan, A. Couet, Corros. Sci. 177, 108955 (2020). https://doi.org/10.1016/j.corsci.2020.108955

C. Falconer, M. Elbakhshwan, W. Doniger, M. Weinstein, K. Sridharan, A. Couet, npj Mater. Degrad. 6(1), 29 (2022). https://doi.org/10.1038/s41529-022-00239-z

S. S. Raiman, J. W. McMurray, R. T. Mayes, C. Abney, K. Myhre, J. R. Keiser, B. R. Betzler, T. Muth, D. Sulejmanovic, Fundamental Studies of Materials Degradation in Molten Chloride Salts Using Targeted Corrosion Testing, Advanced Spectroscopy, and Thermodynamic Modeling, unpublished work (2019)

R. Pillai, W. Sloof, A. Chyrkin, L. Singheiser, W. Quadakkers, Mater. High Temp. 32, 57 (2015)

G.S. Chen, I.W. Sun, K.D. Sienerth, A.G. Edwards, G. Mamantov, J. Electrochem. Soc. 140(6), 1523 (1993). https://doi.org/10.1149/1.2221596

R. T. Mayes, J. M. Kurley III, P. W. Halstenberg, A. McAlister, D. Sulejmanovic, S. S. Raiman, S. Dai, B. A. Pint, Purification of Chloride Salts for Concentrated Solar Applications, Report ORNL/LTR-2018/1052, (2018)

H. Larsson, A. Engström, Acta Materi. 54(9), 2431 (2006). https://doi.org/10.1016/j.actamat.2006.01.020

A. Chyrkin, R. Pillai, H. Ackermann, H. Hattendorf, S. Richter, W. Nowak, D. Grüner, W. Quadakkers, Corros. Sci. 96, 32 (2015). https://doi.org/10.1016/j.corsci.2015.03.019

A. Chyrkin, W. Sloof, R. Pillai, T. Galiullin, D. Grüner, W. Quadakkers, Mater. High Temp. 32, 102 (2015)

R. Pillai, A. Chyrkin, T. Galiullin, E. Wessel, D. Gruener, W.J. Quadakkers, Corros. Sci. 127, 27 (2017). https://doi.org/10.1016/j.corsci.2017.07.021

T.J. Nijdam, W.G. Sloof, Acta Mater. 56(18), 4972 (2008). https://doi.org/10.1016/j.actamat.2008.06.010

K. Yuan, R. Eriksson, R.L. Peng, X.-H. Li, S. Johansson, Y.-D. Wang, Surf. Coat. Technol. 232, 204 (2013). https://doi.org/10.1016/j.surfcoat.2013.05.008

R. Pillai, M.P. Taylor, T. Galiullin, A. Chyrkin, E. Wessel, H. Evans, W.J. Quadakkers, Mater. High Temp. 35(1–3), 78 (2018)

R. Pillai, E. Wessel, W.J. Nowak, D. Naumenko, W.J. Quadakkers, Jom 70(8), 1520 (2018)

H. Larsson, H. Strandlund, M. Hillert, Acta Mater. 54, 945 (2006)

Thermo-Calc, TCFE11, TCS Fe-based Alloys Database, v11.0, 2020, (2020)

Thermo-Calc, TCNI11, TCS Ni-based superalloys Database, v11.0, 2021, (2021)

Thermo-Calc, MOBNI5, TCS Ni-alloys Mobility Database, v5.1, 2019, (2019)

Thermo-Calc, MOBFE, TCS Steel Mobility Database, v6.0, 2020, (2020)

Z. Tokei, H. Viefhaus, K. Hennesen, H.J. Grabke, Diff. React. 72, 3 (2000). https://doi.org/10.4028/www.scientific.net/SSP.72.3

P. Shewmon, Diffusion in Solids, 2nd edn. (Springer, Cham, 2016). https://doi.org/10.1007/978-3-319-48206-4

A. Jalowicka, R. Duan, P. Huczkowski, A. Chyrkin, D. Gruner, B.A. Pint, K.A. Unocic, W.J. Quadakkers, Jom 67(11), 2573 (2015)

S.S. Raiman, J.M. Kurley, D. Sulejmanovic, A. Willoughby, S. Nelson, K. Mao, C.M. Parish, M.S. Greenwood, B.A. Pint, J. Nucl. Mater. 561, 153551 (2022). https://doi.org/10.1016/j.jnucmat.2022.153551

S. Liu, X.-X. Ye, S. Yan, X. Wang, B. Leng, X. Zhou, Corros. Sci. 191, 109761 (2021). https://doi.org/10.1016/j.corsci.2021.109761

R. Pillai, H. Ackermann, K. Lucka, Corros. Sci. 69, 181 (2013). https://doi.org/10.1016/j.corsci.2012.11.040

Acknowledgements

A. Willoughby assisted with the experimental work at ORNL. V. Cox is thanked for hel** with metallography and microstructural characterization respectively. J. Keiser and M. Romedenne are thanked for their valuable comments on the paper. This research was sponsored by the US Department of Energy Office of Nuclear Energy, Molten Salt Reactor Campaign and the Nuclear Energy Advanced Modeling and Simulation program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has been authored by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the US Department of Energy (DOE). The US government retains and the publisher, by accepting the article for publication, acknowledges that the US government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for US government purposes. DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pillai, R., Sulejmanovic, D., Lowe, T. et al. Establishing a Design Strategy for Corrosion Resistant Structural Materials in Molten Salt Technologies. JOM 75, 994–1005 (2023). https://doi.org/10.1007/s11837-022-05647-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05647-9