Abstract

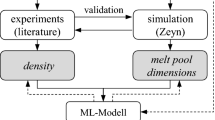

In this work, a Gaussian process (GP)-based machine learning model is developed to predict the remelted depth of single tracks, as a function of combined laser power and laser scan speed in a laser powder bed fusion process. The GP model is trained by both simulation and experimental data from the literature. The mean absolute prediction error magnified by the GP model is only 0.6 μm for a powder bed with layer thickness of 30 μm, suggesting the adequacy of the GP model. Then, the process design maps of two metals, 316L and 17-4 PH stainless steels, are developed using the trained model. The normalized enthalpy criterion of identifying keyhole mode is evaluated for both stainless steels. For 316L, the result suggests that the \( \frac{\Delta H}{{h_{s} }} \ge 30 \) criterion should be related to the powder layer thickness. For 17-4 PH, the criterion should be revised to \( \frac{\Delta H}{{h_{s} }} \ge 25 \).

Similar content being viewed by others

References

G. Tapia and A. Elwany, J. Eng. Ind. 136, 060801 (2014).

R. Rai, J. Elmer, T. Palmer, and T. DebRoy, J. Phys. D 40, 5753 (2007).

J.D. Madison and L.K. Aagesen, Scr. Mater. 67, 783 (2012).

S. Bontha, N.W. Klingbeil, P.A. Kobryn, and H.L. Fraser, J. Mater. Process. Technol. 178, 135 (2006).

C. Kamath, Int. J. Adv. Manuf. Technol. 86, 1659 (2016).

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, and A.M. Rubenchik, J. Mater. Process. Technol 214, 2915 (2014).

M. Yan and P. Yu, in Sintering Techniques of Materials (InTech, 2015). https://doi.org/10.5772/59275.

Q. Guo, C. Zhao, L.I. Escano, Z. Young, L. **ong, K. Fezzaa, W. Everhart, B. Brownd, T. Sun, and L. Chen, Acta Mater. 151, 169 (2018).

A. Gusarov, I. Yadroitsev, P. Bertrand, and I. Smurov, J. Heat Transf. 131, 072101 (2009).

C. Panwisawas, C. Qiu, M.J. Anderson, Y. Sovani, R.P. Turner, M.M. Attallah, J.W. Brooks, and H.C. Basoalto, Comput. Mater. Sci. 126, 479 (2017).

J. Zhang, Y. Zhang, W.H. Lee, L. Wu, H.-H. Choi, and Y.-G. Jung, Met. Powder Rep. (2018). https://doi.org/10.1016/j.mprp.2018.01.003.

Y. Zhang and J. Zhang, J. Mater. Res. 31, 2233 (2016).

Y. Zhang and J. Zhang, Addit. Manuf. 16, 49 (2017).

Y. Zhang, X. **ao, and J. Zhang, Results Phys. 13, 102336 (2019).

J. Zhang, L. Wu, Y. Zhang, and L. Meng, Met. Powder Rep. 74, 20 (2019).

Y. Zhang and J. Zhang, Addit. Manuf. 28, 750 (2019).

E. Alpaydin, Introduction to Machine Learning, 2nd ed. (London: MIT, 2009), pp. 4–16.

Z. Zhu, N. Anwer, Q. Huang, and L. Mathieu, CIRP Ann. (2018). https://doi.org/10.1016/j.cirp.2018.04.119.

G. Tapia, A. Elwany, and H. Sang, Addit. Manuf. 12, 282 (2016).

G. Tapia, S. Khairallah, M. Matthews, W.E. King, and A. Elwany, Int. J. Adv. Manuf. Technol. 94, 3591 (2018).

F. Caiazzo and A. Caggiano, Mater 11, 444 (2018).

J. Zhang, P. Wang, and R.X. Gao, Comput. Ind. 107, 11 (2019).

Mojtaba Mozaffar, Arindam Paul, Reda Al-Bahrani, Sarah Wolff, Alok Choudhary, Ankit Agrawal, Kornel Ehmann, and Jian Cao, Manuf. Lett. 18, 35 (2018).

S. Haykin, Neural Networks: a Comprehensive Foundation, 1st ed. (Prentice Hall PTR: Upper Saddle River, 2009).

C.K. Williams and C.E. Rasmussen, Gaussian Processes for Machine Learning, 1st ed. (London: MIT, 2016).

GPy, GPy: A gaussian process framework in python. https://sheffieldml.github.io/GPy/. Accessed 1 July 2019.

S.A. Khairallah, A.T. Anderson, A. Rubenchik, and W.E. King, Acta Mater. 108, 36 (2016).

I. Choquet, A.J. Shirvan, and H. Nilsson, J. Phys. D 45, 205203 (2012).

M. Courtois, M. Carin, P. Le Masson, S. Gaied, and M. Balabane, J. Phys. D 46, 505305 (2013).

W. Tan, N.S. Bailey, and Y.C. Shin, J. Phys. D 46, 055501 (2013).

I. Yadroitsev, P. Krakhmalev, I. Yadroitsava, S. Johansson, and I. Smurov, J. Mater. Process. Technol. 213, 606 (2013).

T. Eagar and N. Tsai, Weld. J. 62, 346 (1983).

V.-P. Matilainen, H. Piili, A. Salminen, and O. Nyrhilä, Phys. Procedia 78, 377 (2015).

Y. Zhang, Multi-Scale Multi-Physics Modeling of Laser Powder Bed Fusion Process of Metallic Materials With Experiment Validation, PhD thesis, Purdue University, 2018.

D. Hann, J. Iammi, and J. Folkes, J. Phys. D Appl. Phys. 44, 445401 (2011).

C. Kamath, B. El-dasher, G.F. Gallegos, W.E. King, and A. Sisto, Int. J. Adv. Manuf. Technol. 74, 65 (2014).

Acknowledgements

The authors acknowledge the support provided by the National Science Foundation (No. 1836555), Walmart Foundation (project title: Optimal Plastic Injection Molding Tooling Design and Production through Advanced Additive Manufacturing), and Praxair’s TruForm™ AMbition Grant awarded to Indiana University-Purdue University Indianapolis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Meng, L., Zhang, J. Process Design of Laser Powder Bed Fusion of Stainless Steel Using a Gaussian Process-Based Machine Learning Model. JOM 72, 420–428 (2020). https://doi.org/10.1007/s11837-019-03792-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03792-2