Abstract

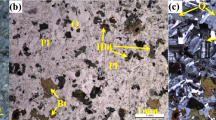

A series of true-triaxial compression tests were performed on red sandstone cubic specimens with a circular hole to investigate the influence of depth on induced spalling in tunnels. The failure process of the hole sidewalls was monitored and recorded in real-time by a micro-video monitoring equipment. The general failure evolution processes of the hole sidewall at different initial depths (500 m, 1000 m and 1500 m) during the adjustment of vertical stress were obtained. The results show that the hole sidewall all formed spalling before resulting in strain rockburst, and ultimately forming a V-shaped notch. The far-field principal stress for the initial failure of the tunnel shows a good positive linear correlation with the depth. As the depth increases, the stress required for the initial failure of the tunnels clearly increased, the spalling became more intense; the size and mass of the rock fragments and depth and width of the V-shaped notches increased, and the range of the failure zone extends along the hole sidewall from the local area to the entire area. Therefore, as the depth increases, the support area around the tunnel should be increased accordingly to prevent spalling.

摘要

为了研究埋深对圆形隧洞诱发板裂破坏的影响, 对含圆形孔洞的立方体红砂岩试样进行了一系 列的真三轴压缩试验, 并采用自制的微型视频监测设备对孔洞洞壁破坏过程进行了实时监测和记录, 得到了不同初始埋深(500、1000 和1500 m)圆形隧洞的竖直应力调整过程中洞壁破坏完整演化过程。 结果表明: 隧洞洞壁在发生应变型岩爆之前, 均形成了板裂破坏, 并最终形成V-型槽。隧洞初始破坏 所需的远场主应力与深度线性**相关。随着深度的增加, 隧洞洞壁初始破坏所需的应力明显增大, 板 裂破坏变得越剧烈, 岩片的尺寸和质量、V-型槽的深度和宽度均增大, 破坏区的范围逐渐由隧洞洞壁 局部扩大至整个洞壁。因此, 随着深度的增加, 隧洞支护区域应相应增大, 以防止板裂破坏的发生。

Similar content being viewed by others

References

LI **-bing, GONG Feng-qiang, TAO Ming, DONG Long-jun, DU Kun, MA Chun-de, ZHOU Zi-long, YIN Tu-bing. Failure mechanism and coupled static-dynamic loading theory in deep hard rock mining: A review [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2017, 9(4): 767–782. DOI: 10.1016/j.jrmge.2017.04.004.

XIE He-**, GAO Ming-zhong, ZHANG Ru, PENG Gao-you, WANG Wen-yong, LI An-qiang. Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper [J]. Rock Mechanics and Rock Engineering, 2019, 52(5): 1475–1490. DOI: 10.1007/s00603-018-1509-y.

MARTIN C D. Seventeenth Canadian geotechnical colloquium: The effect of cohesion loss and stress path on brittle rock strength [J]. Canadian Geotechnique Journal, 1997, 34(5): 698–725. DOI: 10.1139/t97-030.

ZHAO **ng-guang, CAI Ming. Influence of specimen height-to-width ratio on the rockburst characteristics of Tianhu granite under true-triaxial unloading conditions [J]. Canadian Geotechnique Journal, 2015, 52(7): 890–902. DOI: 10.1139/cgj-2014-0355.

ZHOU Hui, MENG Fan-zhen, ZHANG Chuan-qing, HU Da-wei, YANG Fan-jie, LU **g-**g. Analysis of rockburst mechanisms induced by structural planes in deep tunnels [J]. Bulletin of Engineering Geology and the Environment, 2015, 74(4): 1435–1451. DOI: 10.1007/s10064-014-0696-3.

ZHOU Hui, LU **g-**g, XU Rong-chao, ZHANG Chuanqing, MENG Fan-zhen. Critical problems of study of slabbing failure of surrounding rock in deep hard rock tunnel and research progress [J]. Rock and Soil Mechanics, 2015, 36(10): 2737–2749. DOI: 10.16285/j.rsm.201 5.10.001. (in Chinese)

ZHAO **ng-dong, ZHANG Hong-xun, ZHU Wan-cheng. Fracture evolution around pre-existing cylindrical cavities in brittle rocks under uniaxial compression [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 806–815. DOI: 10.1016/S1003-6326(14)63129-0.

ZUO Yu-jun, LI **-bing, ZHOU Zi-long. Determination of ejection velocity of rock fragments during rock burst in consideration of damage [J]. Journal of Central South University, 2005, 12(5): 618–622. DOI: 10.1007/s11771-005-0133-7.

MITELMAN A, ELMO D. Analysis of tunnel support design to withstand spalling induced by blasting [J]. Tunnelling and Underground Space Technology, 2016, 51: 354–361. DOI: 10.1016/j.tust.2015.10.006.

JIA Peng, ZHU Wan-cheng. Dynamic-static coupling analysis on rockburst mechanism in jointed rock mass [J]. Journal of Central South University, 2012, 19(11): 3285–3290. DOI: 10.1007/s11771-012-1405-7.

ZHANG Chuan-qing, FENG **. Case histories of four extremely intense rockbursts in deep tunnels [J]. Rock Mechanics and Rock Engineering, 2012, 45(3): 275–288. DOI: 10.1007/s00603-011-0218-6.

FENG ** underground laboratory (2400 m depth) [J]. Rock Mechanics and Rock Engineering, 2018, 51(4): 1193–1213. DOI: 10.1007/s00603-017-1387-8.

TANG Li-zhong, XIA Kai-wen. Seismological method for prediction of areal rockbursts in deep mine with seismic source mechanism and unstable failure theory [J]. Journal of Central South University, 2010, 17(5): 947–953. DOI: 10.1007/s11771-010-0582-5.

GONG Feng-qiang, YAN **g-yi, LI **-bing, LUO Song. A peak-strength strain energy storage index for rock burst proneness of rock materials [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 117: 76–89. DOI: 10.1016/j.ijrmms.2019.03.020.

JIANG Bang-you, GU Shi-tan, WANG Lian-guo, ZHANG Guang-chao, LI Wen-shuai. Strainburst process of marble in tunnel-excavation-induced stress path considering intermediate principal stress [J]. Journal of Central South University, 2019, 26(4): 984–999. DOI: 10.1007/s11771-019-4065-z.

LI Tian-zheng, LI Yong-xin, YANG **ao-li. Rock burst prediction based on genetic algorithms and extreme learning machine [J]. Journal of Central South University, 2017, 24(9): 2105–2113. DOI: 10.1007/s11771-017-3619-1.

DIEDERICHS M S. The 2003 Canadian geotechnical colloquium: Mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling [J]. Canadian Geotechnique Journal, 2007, 44(9): 1082–1116. DOI: 10.1139/T07-033.

DYSKIN A V, GERMANOVICH L N. Model of rockburst caused by cracks growing near free surface [C]// Rockbursts and Seismicity in Mines. Balkema, Rotterdam, 1993: 169–174. https://eurekamag.com/research/023/047/023047419.php.

DU Kun, TAO Ming, LI **-bing, ZHOU Jian. Experimental study of slabbing and rockburst induced by true-triaxial unloading and local dynamic disturbance [J]. Rock Mechanics and Rock Engineering, 2016, 49(9): 3437–3453. DOI: 10.1007/s00603-016-0990-4.

SHEN Bao-tang, BARTON N. Rock fracturing mechanisms around underground openings [J]. Geomechanics and Engineering, 2018, 16(1): 35–47. DOI: 10.12989/gae.2018.16.1.035.

GONG Qiu-ming, YIN Li-jun, WU Shi-yong, ZHAO Jian, TING Yi-lee. Rock burst and slabbing failure and its influence on TBM excavation at headrace tunnels in **** II hydropower station [J]. Engineering Geology, 2012, 124: 98–108. DOI: 10.1016/j.enggeo.2011.10.007.

HIDALGO K P, NORDLUND E. Failure process analysis of spalling failure-Comparison of laboratory test and numerical modelling data [J]. Tunnelling and Underground Space Technology, 2012, 32: 66–77. DOI: 10.1016/j.tust.2012.05.005.

SU Guo-shao, JIANG Jian-qing, ZHAI Shao-bin, ZHANG Gang-liang. Influence of tunnel axis stress on strainburst: An experimental study [J]. Rock Mechanics and Rock Engineering, 2017, 50(6): 1551–1567. DOI: 10.1007/s00603-017-1181-7.

QIU Shi-Li, FENG **a-ting, ZHANG Chuan-qing, XIANG Tian-bing. Estimation of rockburst wall-rock velocity invoked by slab flexure sources in deep tunnels [J]. Canadian Geotechnique Journal, 2014, 51(5): 520–539. DOI: 10.1139/cgj-2013-0337.

HE Man-chao, LIU Dong-qiao, GONG Wei-li, WANG Cheng-chao, KONG Jie, DU Shuai, ZHANG Shen. Development of a testing system for impact rockbursts [J]. Chinese Journal of Rock Mechanics and Engineering 2014, 39(9): 1729–1739. DOI: 10.13722/j.cnki.jrme. 2014.09.001. (in Chinese)

KUSUI A, VILLAESCUSA E, FUNATSU T. Mechanical behaviour of scaled-down unsupported tunnel walls in hard rock under high stress [J]. Tunnelling and Underground Space Technology. 2016, 60: 30–40. DOI: 10.1016/j.tust.2016.07.012

KUSUI A, VILLAESCUSA E. Seismic response prior to spalling failure in highly stressed underground tunnels [C]// Proceedings of the Seventh International Conference and Exhibition on Mass Mining. Sydney, Australia, 2016. https://www.researchgate.net/publication/303495024.

VILLAESCUSA E, KUSUI A. Evaluating the performance of high energy dissipation capacity surface support systems [C]// Proceedings of International Symposium on Earth Science and Technology. Kyushu, Japan, 2018. https://www.researchgate.net/publication/329826685.

MARTIN C D, KAISER P K, MCCREATH D R. Hoek-brown parameters for predicting the depth of brittle failure around tunnels [J]. Canadian Geotechnique Journal, 1999, 36(1): 136–151. DOI: 10.1139/t98-072.

ZHU Wan-cheng, LI Zhan-hai, ZHU Li-kai, TANG Chun-an. Numerical simulation on rockburst of underground opening triggered by dynamic disturbance [J]. Tunnelling and Underground Space Technology, 2010, 25(5): 587–599. DOI: 10.1016/j.tust.2010.04.004.

MAZAIRA A, KONICEK P. Intense rockburst impacts in deep underground constructions and their prevention [J]. Canadian Geotechnique Journal, 2015, 52(10): 1426–1439. DOI: 10.1139/cgj-2014-0359.

KAISER P K, CAI M. Design of rock support system under rockburst condition [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2012, 4(3): 215–227. DOI: 10.3724/SP.J.1235.2012.00215.

GONG Feng-qiang, LUO Yong, LI **-bing, SI Xue-feng, TAO Ming. Experimental simulation investigation on rockburst induced by spalling failure in deep circular tunnels [J]. Tunnelling and Underground Space Technology, 2018, 81: 413–427. DOI: 10.1016/j.tust.2018.07.035.

GONG Feng-qiang, SI Xue-feng, LI **-bing, WANG Shan-yong. Experimental investigation of strain rockburst in circular caverns under deep three-dimensional high-stress conditions [J]. Rock Mechanics and Rock Engineering, 2019, 52(5): 1459–1474. DOI: 10.1007/s00603-018-1660-5.

GONG Feng-qiang, WU Wu-xing, LI Tian-bin, SI Xue-feng. Experimental simulation and investigation of spalling failure of rectangular tunnel under different three-dimensional stress states [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 122: 104081. DOI: 10.1016/j.ijrmms.2019.104081.

LUO Yong, GONG Feng-qiang, LIU Dong-qiao, Wang Shan-yong, SI Xue-feng. Experimental simulation analysis of the process and failure characteristics of spalling in D-shaped tunnels under true-triaxial loading conditions [J]. Tunnelling and Underground Space Technology, 2019, 90: 42–61. DOI: 10.1016/j.tust.2019.04.020.

CHANDLER N. Develo** tools for excavation design at Canada’s Underground Research Laboratory [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1229–1249. DOI: 10.1016/j.ijrmms.2004.09.002.

EDELBRO C. Numerical modelling of observed fallouts in hard rock masses using an instantaneous cohesion-softening friction-hardening model [J]. Tunnelling and Underground Space Technology, 2009, 24(4): 398–409. DOI: 10.1016/j.tust.2008.11.004.

MARTIN C D. Strength of massive Lac du Bonnet granite around underground openings [D]. Winnipeg: University of Manitoba, 1993. https://www.researchgate.net/publication/35053164.

CAI Ming. Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries-insight from numerical modeling [J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(5): 763–772. DOI: 10.1016/j.ijrmms.2007.07.026.

WANG R, KEMENY J M. A new empirical failure criterion for rock under polyaxial compressive stresses [C]// Proceedings of the 35th US rock mechanics symposium. Balkema, Rotterdam, 1995: 453–482. https://www.onepetro.org/conference-paper/ARMA-95-0453

HAIMSON B, CHANG C. A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite [J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(1, 2): 285–296. DOI: 10.1016/S1365-1609(99)00106-9.

MURRELL S A F. A criterion for brittle fracture of rocks and concrete under triaxial stress and the effect of pore pressure on the criterion [C]// Proceedings of the fifth US rock mechanics symposium. 1963: 563–577. https://www.researchgate.net/publication/290486280.

CHEON D S, JEON S, PARK C, SONG W K, PARK E S. Characterization of brittle failure using physical model experiments under polyaxial stress conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(1): 152–160. DOI: 10.1016/j.ijrmms.2010.10.001.

LI Tian-bin, WANG **ang-feng, MENG Lu-bo. A physical simulation test for the rockburst in tunnels [J]. Journal of Mountain Science, 2011, 8(2): 278–285. DOI: 10.1007/s1162 9-011-2116-5.

LU Wen-bo, ZHOU Chuang-bing, CHEN Ming, JIN Li,YAN Peng. Research on transient characteristics of excavation unloading [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(11): 2184–2192. http://www.rockmech.org/CN/Y2008/V27/I11/2184. (in Chinese)

YAN Peng, ZHAO Zhen-guo, LU Wen-bo, FAN Yong, CHEN **angrong, SHAN Zhi-gang. Mitigation of rock burst events by blasting techniques during deep-tunnel excavation [J]. Engineering Geology, 2015, 188: 126–136. DOI: 10.1016/j.enggeo.2015.01.011.

HE Man-chao, XIA Hong-man, JIA Xue-na, GONG Wei-li, ZHAO Fei, LIANG Kang-yuan. Studies on classification, criteria and control of rockbursts [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2012, 4(2): 97–114. DOI: 10.3724/SP.J.1235.2012.00097.

JIANG Quan, FENG **a-ting, XIANG Tian-bing, SU Guo-shao. Rockburst characteristics and numerical simulation based on a new energy index: A case study of a tunnel at 2500 m depth [J]. Bulletin of Engineering Geology and the Environment, 2010, 69(3): 381–388. DOI: 10.1007/s10064-010-0275-1.

CHEN Bing-rui, FENG **a-ting, MING Hua-jun, ZHOU Hui, ZENG **ong-hui, FENG Guang-liang, XIAO Ya-xun. Evolution law and mechanism of rockburst in deep tunnel: Time-delayed rockburst [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(3): 561–569. http://www.rockmech.org/CN/Y2012/V31/I3/561. (in Chinese)

MARTIN C D, READ R S, MARTINO J B. Observations of brittle failure around a circular test tunnel [J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(7): 1065–1073. DOI: 10.1016/S1365-1609(97)90200-8.

JIANG Quan, FENG **a-ting, FAN Yi-lin, FAN Qi-xiang, LIU Guo-feng, PEI Shu-feng, DUAN Shu-qian. In situ experimental investigation of basalt spalling in a large underground powerhouse cavern [J]. Tunnelling and Underground Space Technology, 2017, 68: 82–94. DOI: 10.1016/j.tust.2017.05.020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(41877272, 41472269) supported by the National Natural Science Foundation of China; Project(2017zzts167) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Luo, Y., Gong, Fq., Li, Xb. et al. Experimental simulation investigation of influence of depth on spalling characteristics in circular hard rock tunnel. J. Cent. South Univ. 27, 891–910 (2020). https://doi.org/10.1007/s11771-020-4339-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4339-5

Key words

- deep underground engineering

- circular tunnels

- spalling

- strain rockburst

- true-triaxial loading

- V-shaped notch