Abstract

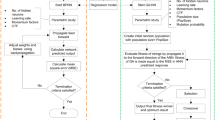

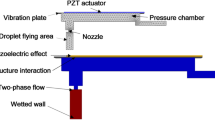

The major challenge in printable electronics fabrication is to effectively and accurately control a drop-on-demand (DoD) inkjet printhead for high printing quality. In this work, an optimal prediction model, constructed with the lumped element modeling (LEM) and the artificial bee colony (ABC) algorithm, was proposed to efficiently predict the combination of waveform parameters for obtaining the desired droplet properties. For acquiring higher simulation accuracy, a modified dynamic lumped element model (DLEM) was proposed with time-varying equivalent circuits, which can characterize the nonlinear behaviors of piezoelectric printhead. The proposed method was then applied to investigate the influences of various waveform parameters on droplet volume and velocity of nano-silver ink, and to predict the printing quality using nano-silver ink. Experimental results show that, compared with two-dimension manual search, the proposed optimal prediction model perform efficiently and accurately in searching the appropriate combination of waveform parameters for printable electronics fabrication.

Similar content being viewed by others

References

SINGH M, HAVERINEN H M, DHAGAT P, JABBOUR G E. Inkjet printing: Process and its applications [J]. Advanced Materials, 2010, 22: 673–685.

MACDONALD E, SALAS R, ESPALIN D, PEREZ M, AGUILERA E, MUSE D, WICKER R B. 3D printing for the rapid prototy** of structural electronics [J]. IEEE Access, 2014, 2: 234–242.

CHEUNG C L, LOOI T, LENDVAY T S, DRAKE J M, FARHAT W A. Use of 3-dimensional printing technology and silicone modeling in surgical simulation: development and face validation in pediatric laparoscopic pyeloplasty [J]. Journal of Surgical Education, 2014, 71(5): 762–767.

JAEHYUNG H, ALAN W, ANTOINE K. Energetics of metal–organic interfaces: New experiments and assessment of the field [J]. Materials Science and Engineering R, 2009, 64: 1–31.

BYUNG J K, JE J H. Geometrical characterization of inkjet-printed conductive lines of nanosilver suspensions on a polymer substrate [J]. Thin Solid Films, 2010, 518: 2890–2896.

VILLANI F, VACCA P, NENNA G, VALENTINO O, BURRASCA G, FASOLINO T, MINARINI C, SALA D J. Inkjet printed polymer layer on flexible substrate for OLED applications [J]. The Journal of Physical Chemistry, 2009, 113(30): 13398–13402.

LIOUA J C, TSENGA F. Multi-dimensional data registration CMOS/MEMS integrated inkjet printhead [J]. Journal of Microelectromechanical Systems, 2011, 19(4): 961–972.

MIETTINEN J, KAIJA K, MANTYSALO M, MANSIKKAMAKI P, KUCHIKI M, TSUBOUCHI M, RONKKA R, HASHIZUME K, KAMIGORI A. Molded substrates for inkjet printed modules [J]. Components and Packaging Technologies, IEEE Transactions on, 2009, 32: 293–301.

SILVERBROOK K. Printhead with multiple actuators in each chamber: US7708387 B2 [P]. 2010.

SANG L, HONG Y, WANG F. Investigatin of viscosity effect on droplet formation in T-shaped micro-channels by numerical and analytical methods [J]. Microfluidics and Nanofluidics, 2009, 6: 6621–6635.

LIU **g, TAN S, YAP Y F, NG M Y, NGUYEN N T. Numerical and experimental investigations of the formation process of ferrofluid droplets [J]. Microfluidics and Nanofluidics, 2011, 11: 177–187.

SARRAZIN F, LOUBIÉRE K, PRAT L, GOURDON C, BONOMETTI T, MAGNAUDET J. Experimental and numerical study of droplet hydrodynamics in microchannels [J]. AIChE Journal, 2006, 52(12): 4061–4070.

XING **u-qing, BUTLER D L, NG S H, WANG Zhen-feng, DANYLUK S, YANG Chun. Simulation of droplet formation and coalescence using lattice Boltzmann-based single-phase model [J]. J Colloid Interface, 2007, 311(2): 609–618.

WASSINK G. Inkjet printhead performance enhancement by feedforward input design based on two-port modeling [D]. Delft University of Technology, 2007.

SEITZ H, HEINZL J. Modeling of a microfluidic device with piezoelectric actuators [J]. Journal of Micromechanics and Microengineering, 2004, 14: 1140–1147.

REIS N, AINSLEY C, DERBY B. Ink-jet delivery of particle suspensions by piezoelectric droplet ejectors [J]. Journal of Applied Physics, 2005, 97: 094903-1-6.

CHUNG J, KO S, GRIGOROPOULOS C P, BIERI N R, DOCKENDORF C, POULIKAKOS D. Damage-free low temperature pulsed laser printing of gold nanoinks on polymers [J]. Journal of Heat Transfer, 2005, 127(7): 724–732.

KWON K. Waveform design methods for piezo inkjet dispensers based on measured meniscus motion [J]. Journal of Microelectromechanical, Systems, 2009, 18(5): 1118–1125.

GALLAS Q, HOLAMAN R, NISHIDA T, CARROLL B, SHEPLAK M, CATTAFESTA L. Lumped element modeling of piezoelectricdriven synthetic jet actuators [J]. AIAA Journal, 2003, 41(2): 240–247.

PRASAD S. Two-Port electroacoustic model of a piezoelectric composite circular plate [D]. Florida, America: University of Florida, 2002.

BLACKSTOCK D T. Fundamentals of physical acoustics [M]. New York: John Wiley & Sons, Inc., 2000: 145.

WHITE F M. Fluid mechanics [M]. New York: McGraw-Hill, Inc., 1979: 377–379.

KWON K S, KIM W. A waveform design method for high-speed inkjet printing based on self-sensing measurement [J]. Sensors and Actuators A: Physical, 2007, 140(1): 75–83.

GAN H Y, SHAN X, ERIKSSON T, LOK B K, LAM Y C. Reduction of droplet volume by controlling actuating waveforms in inkjet printing for micro-pattern formation [J]. Journal of Micromechanics and Microengineering, 2009, 19(5): 055010-1-8.

Konica minolta inkjet head application note-KM1024 series [R]. Tokyo, Japan: Konica Minolta IJ Technologies. Inc, 2009.

KARABOGA D. An idea based on honey bee swarm for numerical optimization [R]. Kayseri, Turkey: Computer Engineering Department, Engineering Faculty, Erciyes University, 2005.

KARABOGA D, BASTURK B. On the performance of artificial bee colony (ABC) [J]. Applied Soft Computing, 2008, 8(1): 687–697.

PIEFORT V. Finite element modelling of piezoelectric active structures [R]. Bruxelles, Belgium: Dissertation, Department of Mechanical Engineering and Robotics, Universite Libre de Bruxelles, 2001.

CONSTANTINESCU F, GHEORGHE A G, NITESCU M. New circuit models of power BAW resonators [C]// European Microwave Integrated Circuit Conference, European Microwave Week. 2007: 599–603.

ALBAREDA A, PÉREZ R. Non-linear behaviour of piezoelectric ceramics [J]. Springer Series in Materials Science, 2011, 140: 681–726.

GOLUB G, PEREYRA V. Separable nonlinear least squares: The variable projection method and its applications [J]. Inverse Problems, 2003, 19: R1–R26.

WIJSHOFF H. The dynamics of the piezo inkjet printhead operation [J]. Physics Reports, 2010, 491(4/5): 77–177.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(2014AA052101-3, 2014AA052102) supported by the National High Technology Research and Development Program of China; Projects(51205389, 61105067) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

He, Mw., Sun, Ll., Hu, Ky. et al. Analysis of DoD inkjet printhead performance for printable electronics fabrication using dynamic lumped element modeling and swarm intelligence based optimal prediction. J. Cent. South Univ. 22, 3925–3934 (2015). https://doi.org/10.1007/s11771-015-2937-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2937-4