Abstract

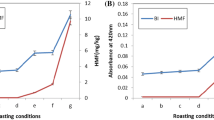

To evaluate the effects of the roasting process on the extraction yield and oil quality, peanut seeds were roasted at different temperatures (130–220 °C) for 20 min prior to the aqueous extraction of both oil and protein hydrolysates with Alcalase 2.4 L. Roasting temperatures did not significantly affect the yields of free oil, whereas the temperature of 220 °C led to a reduced recovery of protein hydrolysates. The color and acid values of peanut oils did not change significantly with roasting temperatures. The enzyme-extracted oil with roasting at 190 °C had a relatively low peroxide value, a strong oxidative stability, and the best flavor score. Using the same seed-roasting temperature (190 °C), quality attributes such as color, acid and peroxide values, phosphorus content and oxidative stability of the enzyme-extracted oil were better than those of the oil obtained by an expeller. After the peanut seeds were roasted at 190 °C for 20 min, with a seeds-to-water ratio of 1:5, an enzyme concentration of 2%, and an incubation time of 3 h, the yields of free oil and protein hydrolysates were 78.6 and 80.1%, respectively. After demulsification of the residual emulsion by a freezing and thawing method, the total free oil yield increased to 86–90%.

Similar content being viewed by others

References

Gunetileke KG, Laurentius SF (1974) Conditions for the separation of oil and protein from coconut milk emulsion. J Food Sci 39:230–233

Bocevska M, Karlovic D, Turkulov J, Pericin D (1993) Quality of corn germ oil obtained by aqueous enzymatic extraction. J Am Oil Chem Soc 70:1273–1277

Domínguez H, Núñez MJ, Lema JM (1995) Aqueous processing of sunflower kernels with enzymatic technology. Food Chem 53:427–434

Hanmoungjai P, Pyle DL, Niranjan K (2001) Enzymatic process for extracting oil and protein from rice bran. J Am Oil Chem Soc 78:817–821

Zhang SB, Wang Z, Xu SY (2007) Optimization of the aqueous enzymatic of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84:97–105

Rosenthal A, Pyle DL, Niranjan K, Gilmour S, Trinca L (2001) Combined effect of operational variables and enzyme activity on aqueous enzymatic extraction of oil and protein from soybean. Enz Microb Technol 28:499–509

Moura JMLN, de Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson LA (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

Moura JMLN, de Johnson LA (2009) Two-stage countercurrent enzyme-assisted aqueous extraction processing of oil and protein from soybeans. J Am Oil Chem Soc 86:283–289

Rhee KC, Cater CM, Mattil KF (1972) Simultaneous recovery of protein and oil from raw peanuts in an aqueous system. J Food Sci 37:90–93

Lanzani A, Petrini NC, Cozzoli O, Gallavresi C, Carola C, Jacini G (1975) On use of enzymes for vegetable oil extraction, a preliminary report. Riv Ital Sostanze Grasse 21:226–229

Sharma A, Khare SK, Gupta MN (2002) Enzyme-assisted aqueous extraction of peanut oil. J Am Oil Chem Soc 79:215–218

Jiang LH, Hua D, Wang Z, Xu SY (2010) Aqueous enzymatic extraction of peanut oil and protein hydrolysates. Food Bioprod Process 88:233–238

Abdulkarim SM, Long K, Lai OM, Muhammad SKS, Ghazali HM (2005) Some physico-chemical properties of Moringa Oleifera seed oil extracted using solvent and aqueous enzymatic methods. Food Chem 93:253–263

Yen GC, Shyu SL (1989) Oxidative stability of sesame oil prepared from sesame seed with different roasting temperatures. Food Chem 31:215–224

Lee YC, Oh SW, Chang J, Kim IH (2004) Chemical composition and oxidative stability of safflower oil prepared from safflower seed roasted with different temperatures. Food Chem 84:1–6

Wang YY (2005) Studies on aqueous enzymatic extraction of oil and protein hydrolysates from peanuts. Ph.D. Dissertation, Jiangnan University, Wuxi, China

Association of Official Analytical Chemists (1995) Official methods of analysis, 16th edn. AOAC International, Gaithersburg

American Oil Chemists’ Society (1999) Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press, Champaign

Yoshida H, Takagi S (1997) Effects of seed roasting temperature and time on the quality characteristics of sesame (Sesamum indicum). J Sci Food Agric 75:19–26

Kim IH, Kim CJ, You JM, Lee KW, Kim CT, Chung SH, Tae BS (2002) Effect of roasting temperature and time on the chemical composition of rice germ oil. J Am Oil Chem Soc 79:413–418

Yen GC (1990) Influence of seed roasting process on the changes in composition and quality of sesame (Sesamum indicum) oil. J Sci Food Agric 50:563–570

Elizalde BE, Dalla Rosa M, Lerici CR (1991) Effect of Maillard reaction volatile products on lipid oxidation. J Am Oil Chem Soc 68:758–762

Yoshimura Y, Ii**a T, Watanabe T, Nakazawa H (1997) Antioxidative effect of Maillard reaction products using glucose–glycine model system. J Agric Food Chem 45:4106–4109

Walradt JP, Pittet AO, Kinlin TE, Muralidhara R, Sanderson A (1971) Volatile components of roasted peanuts. J Agric Food Chem 19:972–979

Fors SM, Erickson CE (1986) Pyrazines in extruded malt. J Sci Food Agric 39:991–1000

Misnawi S, **ap S, Jamilah B, Nazamid S (2004) Effect of polyphenol concentration on pyrazine formation during cocoa liquor roasting. Food Chem 85:73–80

Jung MY, Bock JY, Back SO, Lee TK, Kim JH (1997) Pyrazine contents and oxidative stabilities of roasted soybean oils. Food Chem 60:95–102

Hanmoungjai P, Pyle L, Niranjan K (2000) Extraction of rice bran oil using aqueous media. J Chem Technol Biotechnol 75:348–352

Acknowledgment

This research was supported financially by the Doctoral Research Fund of Henan University of Technology (150339) and the National Natural Science Foundation of China (30600420; 31071617).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Zhang, S.B., Lu, Q.Y., Yang, H. et al. Aqueous Enzymatic Extraction of Oil and Protein Hydrolysates from Roasted Peanut Seeds. J Am Oil Chem Soc 88, 727–732 (2011). https://doi.org/10.1007/s11746-010-1711-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-010-1711-x