Abstract

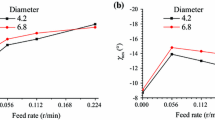

In the aerospace industry, burr removal is an important and expensive part of the manufacturing process. One approach to minimizing burrs is to lower the thrust force in drilling through suitable modification of the drill geometry such as the use of step drills. This paper focuses on the modeling of thrust force and torque for step drills. A mechanistic model capturing the various material removal mechanisms, i.e. oblique cutting, orthogonal cutting, and indentation, active on different sections of the step drill is developed. Subsequently, a series of experiments is conducted to calibrate and validate the model. The validation results show that the predicted thrust and torque values are in good agreement with measured values, although the torque is slightly underestimated. The validated model was further used to investigate the effects of step drill geometry parameters on the thrust force and torque. The model predictions suggest that the thrust force increases and the torque decreases for larger secondary point angles and inner diameters.

Similar content being viewed by others

References

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy, Ti-6Al-4 V. Ann CIRP 48:73–76

Ko SL, Lee JK (2001) Analysis of burr formation in drilling with a new-concept drill. J Mater Process Tech 113:392–398

Lauderbaugh LK (2009) Analysis of the effects of process parameters on exit burrs in drilling using a combined simulation and experimental approach. J Mater Process Tech 209:1909–1919

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2007) Methodology of Taguchi optimization for multi-objective drilling problem to minimize burr size. Int J Adv Manuf Tech 34:1–8

Ko SL, Chang JE (2003) Development of drill geometry for burr minimization in drilling. CIRP Ann Manuf Tech 52:45–48

Ko SL, Chang JE, Yang GE (2003) Burr minimizing scheme in drilling. J Mater Process Tech 140:237–242

Saunders LKL, Mauch CA (2001) An exit burr model for drilling of metals. ASME J Manuf Sci Eng 123:562–566

Pilný L, DeChiffre L, Píška M, Villumsen MF (2012) Hole quality and burr reduction in drilling aluminum sheets. CIRP J Manuf Sci Tech 5:102–107

Armarego EJA (1998) A generic mechanics of cutting approach to predictive technological performance modeling of the wide spectrum of machining operations. Mach Sci Tech 2:191–211

Kapoor SG, Devor RE, Zhu R, Gajjela R, Parakkal G, Smithey D (1998) Development of mechanistic models for the predictions of machining performance: model-building methodology. Mach Sci Tech 2:213–238

Constantin C, Croitoru SM, Constantin G, Bisu CF (2010) 3D FEM analysis of cutting processes. In: Proceedings of the 3rd WSEAS International Conference on Visualization, Imaging and Simulation. World Scientific and Engineering Academy and Society, pp 41–46

Ma L, Marusich TD, Usui S, Wadell J, Marusich K, Zamorano L, Elangovan H (2011) Validation of finite element modeling of drilling processes with solid tooling in metals. Adv Mater Res 223:182–190

Isbilir O, Ghassemieh E (2011) Finite element analysis of drilling titanium alloy. Proced Eng 10:1877–1882

Chandrasekharan V, Kapoor SG, DeVor RE (1998) A mechanistic model to predict the cutting force system for arbitrary drill point geometry. ASME J Manuf Sci Eng 120:563–570

Paul A, Kapoor SG, DeVor RE (2005) A chisel edge model for arbitrary drill point geometry. ASME J Manuf Sci Eng 127:23–32

Gupta K, Ozdoganlar OB, Kapoor SG, DeVor RE (2003) Modeling and prediction of hole profile in drilling, Part 1: modeling drill dynamics in the presence of drill alignment errors. ASME J Manuf Sci Eng 125:6–13

Sahu SK, DeVor RE, Kapoor SG (2004) Modeling of forces for drills with chip-breaking grooves. ASME J Manuf Sci Eng 126:555–564

Elhachimi M, Torbaty S, Joyot P (1999) Mechanical modeling of high speed drilling. 1: predicting torque and thrust. Int J Mach Tool Manuf 39:553–568

Gong Y, Lin C, Ehmann KF (2005) Dynamics of initial penetration in drilling: part 1: mechanistic model for dynamic forces. ASME J Manuf Sci Eng 127:280–288

Dargnat F, Darnis P, Cahuc O (2008) Energetical approach for semi-analytical drilling modeling. Mach Sci Tech 12:295–324

Wang J, Zhang Q (2008) A study of high-performance plane rake faced twist drills. Part II: predictive force models. Int J Mach Tool Manuf 48:1286–1295

Chang SF, Bone GM (2009) Thrust force model for vibration-assisted drilling of aluminum 6061-T6. Int J Mach Tool Manuf 49:1070–1076

López de Lacalle LN, Rivero A, Lamikiz A (2009) Mechanistic model for drills with double point-angle edges. Int J Adv Manuf Tech 40:447–457

Iliescu D, Gehin D, Gutierrez ME, Girot F (2010) Modeling and tool wear in drilling of CFRP. Int J Mach Tool Manuf 50:204–213

Rahmé P, Landon Y, Lachaud F, Piquet R, Lagarrigue P (2011) Analytical models of composite material drilling. Int J Adv Manuf Tech 52:609–617

Lee J, Gozen BA, Ozdoganlar OB (2012) Modeling and experimentation of bone drilling forces. J Biomech 45:1076–1083

Zheng F, Lu WF, Wong YS, Foong KWC (2012) An analytical drilling force model and GPU-accelerated haptics-based simulation framework of the pilot drilling procedure for micro-implants surgery training. Comput Method Program Biomed 108:1170–1184

**a RS, Mahdavian SM (2004) Experimental studies of step drills and establishment of empirical equations for the drilling process. Int J Mach Tool Manuf 45:235–240

Tsao CC (2008) Prediction of thrust force of step drill in drilling composite material by Taguchi method and radial basis. Int J Adv Manuf Tech 36:11–18

Tsao CC (2012) Effect of induced dending moment (IBM) on critical thrust force for delamination in step drilling of composites. Int J Mach Tool Manuf 59:1–5

Chandrasekharan V, Kapoor SG, DeVor RE (1995) A mechanistic approach to predicting the cutting forces in drilling: with application to fiber-reinforced composite materials. ASME J Eng Ind 117:559–570

Kachanov LM (1971) Foundations of the theory of plasticity. North-Holland

Sabberwal AJP (1961) Chip section and cutting force during the milling operation. Ann CIRP 10:197–203

Oxford CJ (1955) On the drilling of metals-1. basic mechanics of the process. ASME Trans 77:103–111

Mauch CA, Lauderbaugh LK (1990) Modeling the drilling process: an analytical model to predict thrust force and torque. ASME MD 20:59–65

Acknowledgments

The authors would like to acknowledge the support of Lockheed Martin for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Flachs, J.R., Salahshoor, M. & Melkote, S.N. Mechanistic models of thrust force and torque in step-drilling of Al7075-T651. Prod. Eng. Res. Devel. 8, 319–333 (2014). https://doi.org/10.1007/s11740-014-0531-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0531-5