Abstract

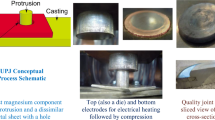

Joining by forming of magnesium alloys is restricted by the limited forming capability of magnesium at room temperature. To form acceptable joints without cracks usually heating of the parts to temperatures of 220°C or more is required. The application of state-of-the-art joining by forming methods (such as self-pierce-riveting or clinching with a contoured die) implicates pre-heating times of at least 3–6 s to achieve joints of acceptable quality. A new joining by forming technology, that is working with a flat anvil as a counter tool instead of the contoured die shall be introduced in this paper. This new technology is offering important advantages especially in joining Mg/Mg, Al/Mg or Fe/Mg connections, most remarkably being the reduction of pre-heating times to less than 1 s, thus allowing for the fast and reliable joining of magnesium parts. Parameter influences on the formation of the connections have been investigated and the values for the tensile strength have been determined for a wide range of connections.

Similar content being viewed by others

References

Behrens A, Hübner S (2005) Heated clinching of magnesium sheet metal. Production engineering, research and development

Hübner S (2005) Clinchen moderner Blechwerkstoffe. Dissertation University Hannover

Doege E, Hübner S, Thoms V, Bräunling S (2003) Thermisch unterstütztes Clinchen von Blechen und Bauteilen aus Magnesium-Knetlegierungen. Forschungsbericht Nr. 203, Europäische Forschungsgesellschaft für Blechverarbeitung e. V., Hannover

Neugebauer R, Mauermann R, Dietrich S (2005a) Chances and challenges in joining by forming with a flat counter tool. In: 11th International conference on sheet metal SheMet 05, Erlangen, Germany, pp. 203–209

Neugebauer R, Dietrich S, Kraus C (2005b) Matrizenloses Clinchverfahren verkürzt Prozesszeiten beim temperierten Fügen von Magnesiumbauteilen. In: 12th Paderborner Symposium Fügetechnik, Paderborn, Germany, pp 100–110

Neugebauer R, Dietrich S, Kraus C (2006) Joining by forming with a flat countertool—a new way of joining magnesium components. In THERMEC’2006, Vancouver, Canada

Redecker M, Roll K, Häußinger S (2005) Magnesium sheet metal forming considering its specific yield behavior. In: 11th International conference on sheet metal SheMet 05, Erlangen, Germany, pp 771–778

Jägg S, Zinn B, Scholtes B (1999) Zum Wechselverformungsverhalten der Magnesiumbasislegierung AZ31. Materialwissenschaft und Werkstofftechnik 30(2):65–71

Dietrich S (2006) Grundlagenuntersuchungen zu neuen matrizenlosen Umformfügeverfahren. Dissertation TU Chemnitz

Acknowledgment

The authors are grateful to the Deutsche Forschungsgemeinschaft DFG (German Research Foundation) for generously supporting our research work in the priority program 1168 “Extending the range of applications of magnesium alloys”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neugebauer, R., Mauermann, R., Dietrich, S. et al. A new technology for the joining by forming of magnesium alloys. Prod. Eng. Res. Devel. 1, 65–70 (2007). https://doi.org/10.1007/s11740-007-0045-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0045-5