Abstract

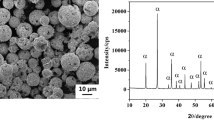

Plasma spray is one of the suitable technologies to deposit carbide coatings with high melting point, such as ZrC. However, in the spray processes performed under atmosphere, oxidation of the carbide powder is inevitable. To investigate the influence of the oxidation behavior of feedstock on microstructure and ablation resistance of the deposited coating, ZrC coatings were prepared by atmospheric and vacuum plasma spray (APS and VPS) technologies, respectively. SiC-coated graphite was applied as the substrate. The obtained results showed that the oxidation of ZrC powder in APS process resulted in the formation of ZrO and Zr2O phases. Pores and cracks were more likely to be formed in the as-sprayed APS-ZrC coating. The VPS-ZrC coating without oxides possessed denser microstructure, higher thermal diffusivity, and lower coefficients of thermal expansion as compared with the APS-ZrC coating. A dense ZrO2 layer would be formed on the surface of the VPS-ZrC-coated sample during the ablation process and the substrate can be protected sufficiently after being ablated in high temperature plasma jet. However, the ZrO2 layer, formed by oxidation of the APS-ZrC coating having loose structure, was easy to be washed away by the shearing action of the plasma jet.

Similar content being viewed by others

References

J.X. Zhao, R.C. Bradt, and P.L. Walker, Jr., Effect of Air Oxidation at 873 K on the Mechanical Properties of a Carbon-Carbon Composite, Carbon, 1985, 23, p 9-13

E. Fitzer, The Future of Carbon-Carbon Composites, Carbon, 1987, 25, p 163-190

M.M. Opeka, I.G. Talmy, E.J. Wuchina, and J.A. Zaykoski, Mechanical, Thermal, and Oxidation Properties of Refractory Hafnium and Zirconium Compounds, J. Eur. Ceram. Soc., 1999, 19, p 2405-2414

H.O. Pierson, Handbook of Refractory Carbides and Nitrides, William Andrew Publishing/Noyes, Westwood, NJ, 1996, p 68

M. Ding, H.S. Zhang, C. Zhang, and X. **, Characterization of ZrC Coatings Deposited on Biomedical 316L Stainless Steel by Magnetron Sputtering Method, Surf. Coat. Technol., 2013, 224, p 34-41

V. Craciun, E.J. McCumiskey, and M. Hanna, Very Hard ZrC Thin Films Grown by Pulsed Laser Deposition, J. Eur. Ceram. Soc., 2013, 33, p 2223-2226

K. Minato, T. Ogawa, T. Koya, and H. Sekino, Retention of Fission Product Caesium in ZrC-Coated Fuel Particles for High-Temperature Gas-Cooled Reactors, J. Nucl. Mater., 2000, 279, p 181-188

Z. Wang, S. Dong, and X. Zhang, Fabrication and Properties of Cf/SiC-ZrC Composites, J. Am. Ceram. Soc., 2008, 91, p 3434-3436

G. Wen, S. Sui, L. Song, X. Wang, and L. **a, Formation of ZrC Ablation Protective Coatings on Carbon Material by Tungsten Inert Gas Cladding Technique, Corros. Sci., 2010, 52, p 3018-3022

Zhaoqian Li, Hejun Li, Wei Li, Jie Wang, Shouyang Zhang, and Juan Guo, SiC Coating for Carbon/Carbon Composites by Solid Phase Infiltration, Appl. Surf. Sci., 2011, 258, p 565-571

Sun Wei, **ong **ang, Huang Bai-yun, Li Guo-dong, Zhang Hong-bo, Chen Zhao-ke, and Zheng **ang-Lin, ZrC Ablation Protective Coating for Carbon/Carbon Composites, Carbon, 2009, 47, p 3368-3371

B. Liu, C. Liu, Y. Shao, J. Zhu, B. Yang, and C. Tang, Deposition of ZrC-Coated Particle for HTR with ZrCl4 Powder, Nucl. Eng. Des., 2012, 25, p 1349-1353

Lech Pawlowski, The Science and Engineering of Thermal Spray Coatings, Wiley, London, 2008

M. Tului, B. Giambi, S. Lionetti, G. Pulci, F. Sarasini, and T. Valente, Silicon Carbide Based Plasma Sprayed Coatings, Surf. Coat. Technol., 2012, 207, p 182-189

H. Wu, H. Li, Q. Fu, D. Yao, Y. Wang, C. Ma, and J. Wei, Microstructures and Ablation Resistance of ZrC Coating for SiC-Coated Carbon/Carbon Composites Prepared by Supersonic Plasma Spraying, J. Therm. Spray Technol., 2011, 20, p 1286-1291

C. Hu, Y. Niu, H. Li, M. Ren, X. Zheng, and J. Sun, SiC Coatings for Carbon/Carbon Composites Fabricated by Vacuum Plasma Spraying Technology, J. Therm. Spray Technol., 2012, 21, p 16-22

Y.R. Niu, X.B. Zheng, C.X. Ding, H. Li, C. Hu, M.S. Ren, and J.L. Sun, Microstructure Characteristics of Silicon Carbide Coatings Fabricated on C/C Composites by Plasma Spraying Technology, Ceram. Int., 2011, 37, p 1675-1680

Y. Zhang, J. Zhang, and Z. Fu, Oxidation Resistance Analysis of Zirconium Carbide Sintered by Hot-Pressing, J. Chin. Ceram. Soc., 2013, 41, p 901-904 (in Chinese)

F. Tarasi, M. Medraj, A. Dolatabadi, J. Oberste-Berghaus, and C. Moreau, Enhancement of Amorphous Phase Formation in Alumina-YSZ Coatings Deposited by Suspension Plasma Spray Process, Surf. Coat. Technol., 2013, 220, p 191-198

K.H. Stern, Metallurgical and Ceramic Protective Coatings, Springer, Berlin, 2012, p 197

Ryan P. Haggerty, Pankaj Sarin, Zlatomir D. Apostolov, Patrick E. Driemeyer, and Waltraud M. Kriven, Thermal Expansion of HfO2 and ZrO2, J. Am. Ceram. Soc., 2014, 97(7), p 2213-2222

D. Hu, X. Zheng, Y. Niu, H. Ji, F. Chong, and J. Chen, Effect of Oxidation Behavior on the Mechanical and Thermal Properties of Plasma Sprayed Tungsten Coatings, J. Therm. Spray Technol., 2008, 17, p 377-384

Acknowledgments

This work was jointly supported by the National Natural Science Foundation (for Young Scholar) of China under Grant 51102267 and Shanghai Science and Technology R&D Fund under Grant 11ZR1442100.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Hu, C., Ge, X., Niu, Y. et al. Influence of Oxidation Behavior of Feedstock on Microstructure and Ablation Resistance of Plasma-Sprayed Zirconium Carbide Coating. J Therm Spray Tech 24, 1302–1311 (2015). https://doi.org/10.1007/s11666-015-0307-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0307-2