Abstract

An efficient approach for virtual prediction of melt pool geometry and temperature distribution in selective laser melting (SLM) is required to optimize the process parameters for eventually printing high-fidelity parts. In this study, the melt pool geometry in the SLM process was simulated by employing Ansys Additive, the commercial finite element analysis software tool. First, a single track of 4 mm length was modeled for Inconel 718 material by varying the process parameters. Validations with existing studies were performed to ensure the reliability of the FE model. Further, a process map exhibiting the optimum process parameters window for SLMed Inconel 718 was developed, which can be used to avoid process-induced defects such as lack of fusion, balling, and keyholing. The response surface methodology design of experiment technique and ANOVA-based regression modeling were used to relate the vital SLM process parameters with the melt pool geometry. The statistical analysis results showed that maximum melt pool depth and width are obtained at maximum laser power and at minimum scan speed and layer thickness. The proposed approach facilitates robust 3D printing by avoiding common process-induced defects as well as allows the tuning of vital process parameters for fabricating superior quality SLM builds.

Similar content being viewed by others

References

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23, p 1917–1928.

D.G. Ahn, Direct Metal Additive Manufacturing Processes and their Sustainable Applications for Green Technology: A Review, Int. J. Precis. Eng. Manuf. Green. Technol., 2016, 3, p 381–395.

M. Seifi, M. Gorelik, J. Waller, N. Hrabe, N. Shamsaei, S. Daniewicz and J.J. Lewandowski, Progress Towards Metal Additive Manufacturing Standardization to Support Qualification and Certification, JOM, 2017, 69(3), p 439–455.

P. Kumar, J. Farah, J. Akram, C. Teng, J. Ginn and M. Misra, Influence of Laser Processing Parameters on Porosity in INCONEL 718 During Additive Manufacturing, Int. J. Adv. Manuf. Technol., 2019, 103, p 1497–1507.

N. Kladovasilakis, P. Charalampous, I. Kostavelis, D. Tzetzis and D. Tzovaras, Impact of Metal Additive Manufacturing Parameters on the Powder Bed Fusion and Direct Energy Deposition Processes: A Comprehensive Review, Prog. Addit. Manuf., 2021, 6, p 349–365.

M.A. Ryder, C.J. Montgomery, M.J. Brand, J.S. Carpenter, P.E. Jones, A.G. Spangenberger and D.A. Lados, Melt Pool and Heat Treatment Optimization for the Fabrication of High-Strength and High-Toughness Additively Manufactured 4340 Steel, J. Mater. Eng. Perform., 2021, 30, p 5426–5440.

H. Ali, H. Ghadbeigi and K. Mumtaz, Processing Parameter Effects on Residual Stress and Mechanical Properties of Selective Laser Melted Ti6Al4V, J. Mater. Eng. Perform., 2018, 27, p 4059–4068.

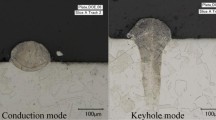

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, J.W. Gibbs, D.E. Hahn, C. Kamath and A.M. Rubenchik, Observation of Keyhole-mode Laser Melting in Laser Powder-bed Fusion Additive Manufacturing, J. Mater. Process. Technol., 2014, 214, p 2915–2925.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A.E. Wilson-Heid, A. De and W. Zhang, Additive Manufacturing of Metallic Components- PROCESS, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

P. Promoppatum and S.C. Yao, Analytical Evaluation of Defect Generation for Selective Laser Melting of Metals, Int. J. Adv. Manuf. Technol., 2019, 103, p 1185–1198.

W.R. Kim, G.B. Bang, J.H. Park, T.W. Lee, B.S. Lee, S.M. Yang, G.H. Kim, K. Lee and H.G. Kim, Microstructural Study on a Fe-10Cu Alloy Fabricated by Selective Laser Melting for Defect-Free Process Optimization Based on the Energy Density, J. Mater. Res. Technol., 2020, 9(6), p 12834–12839.

S. Gao, X. Yan, C. Chang, E. Aubry, M. Liu, H. Liao and N. Fenineche, Effect of Laser Energy Density on Surface Morphology, Microstructure, and Magnetic Properties of Selective Laser Melted Fe-3wt.% Si Alloys, J. Mater. Eng. Perform., 2021, 30, p 5020–5030.

J.J.S. Dilip, S. Zhang, C. Teng, K. Zeng, C. Robinson, D. Pal and B.E. Stucker, Influence of Processing Parameters on the Evolution of Melt Pool, Porosity, and Microstructures in Ti-6Al-4V Alloy Parts Fabricated by Selective Laser Melting, Prog. Addit. Manuf., 2017, 2, p 157–167.

X. Zhang, B. Mao, L. Mushongera, J. Kundin and Y. Liao, Laser Powder Bed Fusion of Titanium Aluminides: An Investigation on Site-Specific Microstructure Evolution Mechanism, Mater. Des., 2021, 201, 109501.

T.G. Spears and S.A. Gold, In-process Sensing in Selective Laser Melting (SLM) Additive Manufacturing. Integr, Mater. Manuf. Innov., 2016, 5, p 16–40.

S. Shrestha and K. Chou, Single Track Scanning Experiment in Laser Powder Bed Fusion Process, Proced. Manuf., 2018, 26, p 857–864.

L. Scime and J.L. Beuth, Melt Pool Geometry and Morphology Variability for the Inconel 718 Alloy in a Laser Powder Bed Fusion Additive Manufacturing Process, Addit. Manuf., 2019, 29, 100830.

S.A. Khairallah and A.T. Anderson, Mesoscopic Simulation Model of Selective Laser Melting of Stainless-Steel Powder, J. Mater. Process. Technol., 2014, 214, p 2627–2636.

B. Cheng, L. Loeber, H. Willeck, U. Hartel and C. Tuffile, Computational Investigation of Melt Pool Process Dynamics and Pore Formation in Laser Powder Bed Fusion, J. Mater. Eng. Perform., 2019, 28, p 6565–6578.

M. Khorasani, A.H. Ghasemi, M. Leary, L. Cordova, E. Sharabian, E. Farabi, I. Gibson, M. Brandt and B. Rolfe, A Comprehensive Study on Meltpool Depth in Laser-based Powder Bed Fusion of Inconel 718, Int. J. Adv. Manuf. Technol., 2022, 120, p 2345–2362.

S.A. Khairallah, A.T. Anderson, A.M. Rubenchik and W.E. King, Laser Powder-bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones, Acta Mater., 2016, 108, p 36–45.

N. Diaz Vallejo, C. Lucas, N. Ayers, K. Graydon, H. Hyer and Y. Sohn, Process Optimization and Microstructure Analysis to Understand Laser Powder Bed Fusion of 316L Stainless Steel, Metals, 2021, 11, p 832.

S. Jelvani, R. Shoja Razavi, M. Barekat and M. Dehnavi, Empirical-Statistical Modeling and Prediction of Geometric Characteristics for Laser-Aided Direct Metal Deposition of Inconel 718 Superalloy, Met. Mater. Int., 2019, 26, p 668–681.

M. Balichakra, S. Bontha, P. Krishna and V.K. Balla, Laser Surface Melting of γ-TiAl Alloy: An Experimental and Numerical Modelling Study, Mater. Res. Expr., 2019, 6, 046543.

P. Tan, F. Shen, B. Li and K. Zhou, A Thermo-metallurgical-Mechanical Model for Selective Laser Melting of Ti6Al4V, Mater. Des., 2019, 168, 107642.

Y.M. Arisoy, L.E. Criales and T.R. Ozel, Modelling and Simulation of Thermal Field and Solidification in Laser Powder Bed Fusion of Nickel Alloy IN625, Opt. Laser Technol., 2019, 109, p 278–292.

M.J. Ansari, D.S. Nguyen and H.S. Park, Investigation of SLM Process in Terms of Temperature Distribution and Melting Pool Size: Modeling and Experimental Approaches, Materials, 2019, 12, p 1272.

S. Waqar, Q. Sun, J. Liu, K. Guo and J. Sun, Numerical Investigation of Thermal Behavior and Melt Pool Morphology in Multi-track Multi-layer Selective Laser Melting of the 316L Steel, Int. J. Adv. Manuf. Technol., 2021, 112, p 879–895.

M. Majeed, H.M. Khan, G. Wheatley and R. Situ, A Numerical Approach to Assess the Impact of the SLM Laser Parameters on Thermal Variables, J. Addit. Manuf. Technol., 2021, 1(3), p 589–589.

C. Wang, X.P. Tan, S.B. Tor and C.S. Lim, Machine Learning in Additive Manufacturing: State-of-the-Art and Perspectives, Addit. Manuf., 2020, 36, 101538.

N. Kouraytem, X. Li, W. Tan, B. Kappes and A.D. Spear, Modeling Process–Structure–Property Relationships in Metal Additive Manufacturing: A Review on Physics-Driven Versus Data-Driven Approaches, J. Phys. Mater., 2021, 4, 032002.

X. Qi, G. Chen, Y. Li, X. Cheng and C. Li, Applying Neural-Network-Based Machine Learning to Additive Manufacturing: Current Applications Challenges and Future Perspectives, Engineering, 2019, 5, p 721–729.

E. Maleki, S. Bagherifard and M. Guagliano, Application of Artificial Intelligence to Optimize the Process Parameters Effects on Tensile Properties of Ti-6Al-4V Fabricated by Laser Powder-Bed Fusion, Int. J. Mech. Mater. Des., 2022, 18, p 199–222.

H. Tupac-Yupanqui and A. Armani, Additive Manufacturing of Functional Inconel 718 Parts from Recycled Materials, J. Mater. Eng. Perform., 2021, 30, p 1177–1187.

Y. Li and D. Gu, Parametric Analysis of Thermal Behaviour During Selective Laser Melting Additive Manufacturing of Aluminium Alloy Powder, Mater. Des., 2014, 63, p 856–867.

J. Yin, H. Zhu, L. Ke, W. Lei, C. Dai and D. Zuo, Simulation of Temperature Distribution in Single Metallic Powder Layer for Laser Micro-Sintering, Comput. Mater. Sci., 2012, 53, p 333–339.

P. He, C. Sun and Y. Wang, Material Distortion in Laser-Based Additive Manufacturing of Fuel Cell Component: Three-Dimensional Numerical Analysis, Addit. Manuf., 2021, 46, 102188.

J.P. Choi, G.H. Shin, S. Yang, D.Y. Yang, J.S. Lee, M. Brochu and J.H. Yu, Densification and Microstructural Investigation of Inconel 718 Parts Fabricated by Selective Laser Melting, Powder Technol., 2017, 310, p 60–66.

W.Y. Chen, X. Zhang, M. Li, R. Xu, C. Zhao and T. Sun, Laser Powder Bed Fusion of INCONEL 718 on 316 Stainless Steel, Addit. Manuf., 2020, 36, 101500.

T.E. Shelton, G.R. Cobb, C.R. Hartsfield, B.M. Doane, C.C. Eckley and R.A. Kemnitz, The Impact of Laser Control on the Porosity and Microstructure of Selective Laser Melted Nickel Superalloy 718, Results Mater., 2021, 11, 100211.

O. Gokcekaya, T. Ishimoto, S. Hibino, J. Yasutomi, T. Narushima and T. Nakano, Unique Crystallographic Texture Formation in Inconel 718 by Laser Powder Bed Fusion and Its Effect on Mechanical Anisotropy, Acta Mater., 2021, 212, 116876.

M. Bayat, S. Mohanty and J.H. Hattel, Multiphysics Modelling of Lack-of-Fusion Voids Formation and Evolution in IN718 Made by Multi-Track/multi-Layer L-PBF, Int. J. Heat Mass. Transf., 2019, 139, p 95–114.

C. Kusuma, S.H. Ahmed, A. Mian and R. Srinivasan, Effect of Laser Power and Scan Speed on Melt Pool Characteristics of Commercially Pure Titanium, J. Mater. Eng. Perform., 2017, 26, p 3560–3568.

J. Jakumeit, C. Huang, R. Laqua, J. Zielinski and J.H. Schleifenbaum, Effect of Evaporated Gas Flow on Porosity and Microstructure of IN718 Parts Produced by LPBF-Processes, IOP Conf. Ser. Mater. Sci. Eng., 2020, 861, p 012011.

U. Segurajauregi, A. Alvarez-Vazquez, M. Muniz-Calvente, I. Urresti and H. Naveiras, Fatigue Assessment of Selective Laser Melted Ti-6Al-4V: Influence of Speed Manufacturing and Porosity, Metals, 2021, 11, p 1022.

P. Kumar, P. Chakravarthy, S.K. Manwatkar and S. Murty, Effect of Scan Speed and Laser Power on the Nature of Defects, Microstructures and Microhardness of 3D-Printed Inconel 718 Alloy, J. Mater. Eng. Perform., 2019, 28, p 6565–6578.

Acknowledgments

The Ministry of Human Resource Development, Government of India, is sincerely acknowledged by the lead author for providing financial assistance in the form of a research scholarship. This research received no particular funding in any form.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Shukla, M. Numerical Modeling of Selective Laser Melting: Influence of Process Parameters on the Melt Pool Geometry. J. of Materi Eng and Perform 32, 7998–8013 (2023). https://doi.org/10.1007/s11665-022-07693-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07693-5