Abstract

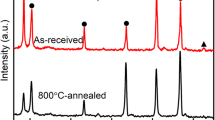

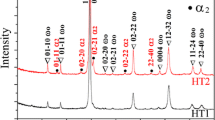

In this paper, the γ(TiAl) sheets were prepared using Ti and Al foils by cold rolling and diffusion annealing, followed by hot isostatic pressing. Heat treatment was carried out at 1250 °C and 1280 °C and a holding time of 12 h. X-ray diffraction (XRD), transmission electron microscopy (TEM), and high-resolution TEM were employed to analyze the microstructure and phase composition of the obtained material. The results revealed that the alloy mainly consisted of α2(Ti3Al) and γ(TiAl) phases. The residual α2(Ti3Al) was found in the grains, and the γ(TiAl) phase formed the matrix structure. A calculation of the mismatch degree revealed that the presence of α2(Ti3Al) could strengthen the matrix. After heat treatment at 1280 °C for 12 h, the degree of mismatch between the α2(Ti3Al) and γ(TiAl) phases was smaller, and the TiAl alloy with a high content of the γ(TiAl) phase was easier to prepare. The orientation relationship between the γ(TiAl) and α2(Ti3Al) phases after heat treatment at different temperatures was examined. After heat treatment at 1280 °C for 12 h, Ti3Al and the TiAl matrix exhibited a preferential orientation relationship.

Similar content being viewed by others

Reference

A. Mohammadnejad, A. Bahrami and L.T. Khajavi, Microstructure and Mechanical Properties of Spark Plasma Sintered Nanocrystalline TiAl-xB Composites (0.0 < x < 1.5 at.%) Containing Carbon Nanotubes, J. Mater. Eng. Perform., 2021, 30, p 4380–4392.

B. Chen, Z.S. Xu, Y. Liu, B. Xue and W.D. Ma, Tribological Performance and Tribofilm Evolution of TiAl Matrix Composites with Silver and Titanium Diboride at Elevated Temperatures, J. Mater. Eng. Perform., 2020, 29, p 5655–5662.

L.K. Wu, J.J. Wu, W.Y. Wu, F.H. Cao and M.Y. Jiang, Sol–gel-Based Coatings for Oxidation Protection of TiAl Alloys, J. Mater. Sci., 2020, 55, p 6330–6351.

W. Sun, F.H. You, F.T. Kong, X.P. Wang and Y.Y. Chen, Effect of Residual Stresses on the Mechanical Properties of Ti-TiAl Laminate Composites Fabricated by Hot-Pack Rolling, Mater. Charact., 2020, 166, p 110394.

W. Wang, H.X. Zhou, Q.J. Wang, Y. Gao and K.S. Wang, Influence of Mechanical Alloying and Sintering Temperature on the Microstructure and Mechanical Properties of a Ti-22Al-25Nb Alloy, J. Mater. Eng. Perform., 2020, 56, p 815–827.

J.G. Li, R. Hu, J.R. Yang, Z.T. Gao, K.R. Zhang and X.Y. Wang, Evolution and Micromechanical Properties of Interface Structures in TiNbf/TiAl Composites Prepared by Powder Metallurgy, J. Mater. Sci., 2020, 55, p 12421–12433.

R.R. Chen, Q. Wang, Y.H. Yang, J.J. Guo, Y.Q. Su, H.S. Ding and H.Z. Fu, Brittle–Ductile Transition During Creep in Nearly and Fully Lamellar High-Nb TiAl Alloys, Intermetallics, 2018, 93, p 47–54.

L. Song, X.G. Hu, T.B. Zhang and J.S. Li, Precipitation Behaviors in a Quenched High Nb-Containing TiAl Alloy During Annealing, Intermetallics, 2017, 89, p 79–85.

H.W. Liu, P.D. Bishop and K.P. Plucknett, Densification Behaviour and Microstructural Evolution of Ti-48Al Consolidated by Spark Plasma Sintering, J. Mater. Sci., 2017, 52, p 613–627.

M. Perez-Bravo, I. Madariaga, K. Ostolaza and M. Tello, Microstructural Refinement of a TiAl Alloy by a Two Step Heat Treatment, Scr. Mater., 2005, 53, p 1141–1146.

S. Bolz, M. Oehring, J. Lindemann, F. Pyczak, J. Paul, A. Stark, A. Lippmann and S. Schrüfer, Microstructure and Mechanical Properties of a Forged β-Solidifying γ-TiAl Alloy in Different Heat Treatment Conditions, Intermetallics, 2015, 58, p 71–83.

S.L. Shu, F. Qiu, C.Z. Tong, X.N. Shan and Q.C. Jiang, Effect of Fe, Co and Ni elements on the ductility of TiAl alloy, J. Alloys. Compd., 2014, 617, p 302–305.

H.Z. Niu, S.L. **ao, F.T. Kong, C.J. Zhang and Y.Y. Chen, Microstructure Characterization and Mechanical Properties of TiB2/TiAl In Situ Composite by Induction Skull Melting Process, Mater. Sci. Eng. A, 2012, 532, p 522–527.

D.L. Sun, T. Sun, Q. Wang, X.L. Han, Q. Guo and G.H. Wu, Fabrication of in situ Ti2AlN/TiAl Composites by Reaction Hot Pressing and Their Properties, J. Wuhan. Univ. Technol. Mater. Sci. Ed., 2014, 29, p 126–130.

D.D. Gu, Z.Y. Wang, Y.F. Shen, Q. Li and Y.F. Li, In-situ TiC Particle Reinforced Ti-Al Matrix Composites: Powder Preparation by Mechanical Alloying and Selective Laser Melting Behavior, Appl. Surf. Sci., 2009, 255, p 9230–9240.

X.J. Song, H.Z. Cui, N. Hou, N. Wei, Y. Han, J. Tian and Q. Song, Lamellar Structure and Effect of Ti2AlC on Properties of Prepared in-situ TiAl Matrix Composites, Ceram. Int., 2016, 42, p 13586–13592.

Y. Zhou, D.L. Sun, D.P. Jiang, X.L. Han, Q. Wang and G.H. Wu, Microstructural Characteristics and Evolution of Ti2AlN/TiAl Composites with a Network Reinforcement Architecture During Reaction Hot Pressing Processing, Mater. Charact., 2018, 80, p 28–35.

L.Y. **ang, F. Wang, J.F. Zhu and X.F. Wang, Mechanical Properties and Microstructure of Al2O3/TiAl in situ Composites Doped with Cr, Mater. Sci. Eng. A, 2011, 528, p 3337–3341.

H. Fukutomi, M. Ueno, M. Nakamura, T. Suzuki and S. Kikuchi, Production of TiAl Sheet with Orient Lamellar Microstructure by Diffusional Reaction of Aluminum and Textured Titanium Foils, J. Mater. Trans. JIM., 1999, 40, p 654.

R.G. Zhang and V.L. Acoff, Processing Sheet Materials by Accumulative Roll Bonding and Reaction Annealing from Ti/Al/Nb Elemental Foils, Mater. Sci. Eng. A, 2007, 463, p 67–73.

Y.G. Zhang, Y.F. Han, G.L. Cheng, J.T. Guo, X.J. Wang and D. Feng, Structural Intermetallics, National Defence Industry Press, Bei**g, 2001.

J. Boddoes, W. Wallace and L. Zhao, Current Understanding of Creep Behavior of near γ-Titanium Aluminides, Int. Mater. Rev., 1995, 40, p 197.

D. Hu, Effect of Composition on Grain Refinement in Ti Al-Based Alloys, Intermetallics, 2001, 9, p 1037–1043.

H.Q. Che and Q.C. Fan, Microstructural Evolution During the Ignition/Quenching of Pre-Heated Ti/3Al Powders, J. Alloys. Compd., 2009, 475, p 184–190.

Y.J. Wu and T. Lan, Study on Infiltration Combustion Synthesis (ICS) of TiAl Intermetallic Compound, Rare Met. Mater. Eng., 1996, 25, p 17–20.

L.M. Kang, Y.J. Cai, X.C. Luo, Z.J. Li, X.B. Liu, Z. Wang, Y.Y. Li and C. Yang, Bimorphic Microstructure in Ti-6Al-4V Alloy Manipulated by Spark Plasma Sintering and in-situ Press Forging, Scripta Mater., 2021, 193, p 43–48.

C. Yang, L.M. Kang, X.X. Li, W.W. Zhang, D.T. Zhang, Z.Q. Fu, Y.Y. Li, L.C. Zhang and E.J. Lavernia, Bimodal Titanium Alloys with Ultrafine Lamellar Eutectic Structure Fabricated by Semi-Solid Sintering, Acta Mater., 2017, 132, p 491–502.

P. Liu, D.L. Sun, X.L. Han and Q. Wang, Investigation on the Crystallographic Orientation Relationships and Interface Atomic Structures in an in-situ Ti2AlN/TiAl Composite, Mater. Des., 2017, 130, p 239–249.

K. Zhang, Z.J. Zhang, X.X. Lu, K. Li, Y. Du, J.Z. Long, T. Xu, H. Zhang, L. Chen and Y. Kong, Microstructure and Composition of the Grain/Binder Interface in WC-Ni3Al Composites, Int. Refract. Met. Hard. Mater., 2014, 44, p 88–93.

P. Liu, “Atomic-Scale Investigation on the Ti2AlN/TiAl Interface Models and Deformation Mechanisms,” PhD Thesis, Harbin Institute of Technology, 2019.

H.W. Tian and M. Nemoto, Precipitation Behavior of Nitrides in L10-Ordered TiAl, Intermetallics, 2005, 13, p 1030–1037.

H.Y. Zhang, X.J. Liu, S.Y. Yang, H.Y. Jiang, Z. Shi, M.J. Yang and C.P. Wang, The Clarification of α’’ Phase Precipitate from β Phase in Ti-15Mn Alloy by Mismatch Theory, Mater. Lett., 2017, 202, p 138–141.

Acknowledgments

This work was supported by National Natural Science Foundation of China (No. 51871012), Bei**g Natural Science Foundation (No. 2162024), Fundamental Research Funds for the Central Universities (No. FRF-GF-19-023B), and National Program on Key Basic Research Project (973 Program) (No. 2011CB605502).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Zhang, L. & Ge, G. Study of the Orientation Relationship of the Residual α2(Ti3Al) in γ(TiAl) Sheet After Heat Treatment. J. of Materi Eng and Perform 31, 4224–4231 (2022). https://doi.org/10.1007/s11665-021-06490-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06490-w