Abstract

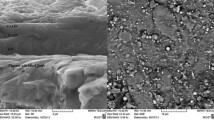

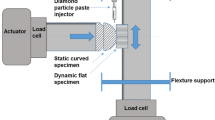

Fretting of mated electronic connectors may be due to extreme increase in contact resistance. We present a detailed analysis of contact resistance by fretting experiments using brass alloys/copper contact pairs. The relationship between wear mechanisms and contact resistance was determined. The influence of fundamental factors such as normal load, displacement amplitude, and current on contact resistance change was also evaluated. It was found out that displacement amplitude, normal load, and current are important parameters for infinite lifetime or stable electrical resistance during fretting condition. Influence of displacement amplitude on the electrical contact performance might be affected by wear debris in the contact area. Electric contact performance could be improved by increasing the power current, which could break down the thick oxide film formed. The predicted working lifetime and reliability requirements of the connector were determined to optimize and extend the service life under the working condition.

Similar content being viewed by others

References

H. Chang, C.H. Pitt, and G.B. Alexander, Novel Method for Preparation of Silver-Tin Oxide Electrical Contacts, J. Mater. Eng. Perform., 1992, 1, p 255–260

J.W. Mcbride, The Relationship Between Surface Wear and Contact Resistance During the Fretting of in vivo Electrical Contacts, IEEE Trans. Compon. Packag. Technol., 2008, 31, p 592–600

Z. Wei, L. Zhang, and T. Shen, Effects of Oxide-Modified Spherical ZnO on Electrical Properties of Ag/ZnO Electrical Contact Material, J. Mater. Eng. Perform., 2016, 134, p 1–10

L. Kogut and K. Komvopoulos, Electrical Contact Resistance Theory for Conductive Rough Surfaces, J. Appl. Phys., 2003, 94, p 3153–3162

J. Hu, K. Zhang, and Q. Yang, Fretting Behaviors of Interface Between CFRP and Coated Titanium Alloy in Composite Interference-Fit Joints Under Service Condition, Mater. Des., 2017, 134, p 91–102

Z. Kong and J. Swingler, Combined Effects of Fretting and Pollutant Particles on the Contact Resistance of the Electrical Connectors, Prog. Nat. Sci. Mater. Int., 2017, 27, p 385–390

S. Sett, K. Das, and A.K. Raychaudhuri, Investigation of Factors Affecting Electrical Contacts on Single Germanium Nanowires, J. Appl. Phys., 2017, 121, p 124503

Z. Kong, R. Huang, and L. Xu, in International Conference on Electrical Contacts. IET. Investigation of electrical properties and morphology of several contact materials after cyclic damp-heat and sliding, 2012, p 426–429

H. Sun, Q. Zhou, and J. Zhu, Analysis on the Fracture of Al-Cu Dissimilar Materials Friction Stir Welding Lap Joint, j. Mater. Eng. Perform., 2017, 26, p 1–8

J. Chen, F. Yang, and K. Luo, Experimental Investigation on the Electrical Contact Behavior of Rolling Contact Connector, Rev. Sci. Instrum., 2015, 86, p 125110

G. Li, X. Fang, and W. Feng, In situ Formation and Do** of Ag/SnO2 Electrical Contact Materials, J. Alloy. Compd., 2017, 716, p 106–111

B.D. Jensen, L.W. Chow, and K. Huang, Effect of Nanoscale Heating on Electrical Transport in RF MEMS Switch Contacts, J. Microelectromech. Syst., 2005, 14, p 935–946

H. Yu, M.T. Kesim, and Y. Sun, Extended Aging of Ag/W Circuit Breaker Contacts: Influence on Surface Structure, Electrical Properties, and UL Testing Performance, J. Mater. Eng. Perform., 2016, 25, p 91–101

E. Larsson, A.M. Andersson, and Å.K. Rudolphi, Grease Lubricated Fretting of Silver Coated Copper Electrical Contacts, Wear, 2017, 376, p 634–642

E. Mengotti, L.I. Duarte, and J. Pippola, Fretting Corrosion: Analysis of the Failure Mechanism for Low Voltage Drives Applications, Microelectron. Reliab., 2014, 54, p 2109–2114

X.L. Liu, Z.B. Cai, S.B. Liu et al., Effect of Roughness on Electrical Contact Performance of Electronic Components, Microelectron. Reliab., 2017, 74, p 100–109

M. Rashid, Some Tribological Influences on the Electrode-Worksheet Interface During Resistance Spot Welding of Aluminum Alloys, J. Mater. Eng. Perform., 2011, 20, p 456–462

J. Neijzen and J. Glashorster, Fretting Corrosion of Tin-Coated Electrical Contacts, IEEE Trans. Compon. Hybrids Manuf. Technol., 1987, 10, p 68–74

T. Liskiewicz, A. Neville, and S. Achanta, in IEEE Holm Conference on Proceedings of the Fifty-Second. IEEE. Impact of corrosion on fretting damage of electrical contacts, Electrical contacts-2006, 2006, p 257–262.

R. Ramesh and R. Gnanamoorthy, Artificial Neural Network Prediction of Fretting Wear Behavior of Structural Steel, En 24 Against Bearing Steel, En 31, J. Mater. Eng. Perform., 2007, 16, p 703–709

H.J. Noh, J.W. Kim, and S.M. Lee, Effect of Grain Size on the Electrical Failure of Copper Contacts in Fretting Motion, Tribol. Int., 2017, 111, p 39–45

V. Deeva and S. Slobodyan, Influence of Gravity and Thermodynamics on the Sliding Electrical Contact, Tribol. Int., 2017, 105, p 299–303

J. Xu and K. Li, The Research on Resistance of Electrical Contact, Electr. Eng. Mater., 2011, 1, p 003

K. Mashimo, and Y. Ishimaru, in 2011 IEEE 57th Holm Conference on Electrical Contacts (Holm). Computational modeling and analysis of a contact pair for the prediction of fretting dependent electrical contact resistance. 2011, p. 1–6.

J. Yifu, K. Weicheng, and S. Tianyuan, Effect of Load on Friction-Wear Behavior of HVOF-Sprayed WC-12Co Coatings, J. Mater. Eng. Perform., 2017, 26, p 3465–3473

K.S. Weil, High-Temperature Electrical Testing of a Solid Oxide Fuel Cell Cathode Contact Material, J. Mater. Eng. Perform., 2004, 13, p 309–315

M. Tan, X. Wang, and Y. Hao, Novel Ag Nanowire Array with High Electrical Conductivity and Fast Heat Transfer Behavior as the Electrode for Film Devices, J. Alloy. Compd., 2017, 701, p 49–54

D.D.L. Chung, Electrical Conduction Behavior of Cement-Matrix Composites, J. Mater. Eng. Perform., 2002, 11, p 194–204

K. Krishnaveni, T.S.N.S. Narayanan, and S.K. Seshadri, Electrodeposited Ni–B Coatings: Formation and Evaluation of Hardness and Wear Resistance, Surf. Coat. Technol., 2006, 99, p 300–308

Z. Wei, L. Zhang, and T. Shen, Effects of Oxide-Modified Spherical ZnO on Electrical Properties of Ag/ZnO Electrical Contact Material, J. Mater. Eng. Perform., 2016, 25, p 3662–3671

X.Q. Wei, B.Y. Man, and M. Liu, Blue Luminescent Centers and Microstructural Evaluation by XPS and Raman in ZnO Thin Films Annealed in Vacuum, N2, and O2, Phys. B Phys. Condens. Matter., 2007, 388, p 145–152

G.D. Khattak, A. Mekki, and M.A. Gondal, Effect of Laser Irradiation on the Structure and Valence States of Copper in Cu-Phosphate Glass by XPS Studies, Appl. Surf. Sci., 2010, 256, p 3630–3635

J.P. Espinós, J. Morales, and A. Barranco, Interface Effects for Cu, CuO, and Cu2O Deposited on SiO2 and ZrO2 XPS Determination of the Valence State of Copper in Cu/SiO2 and Cu/ZrO2 Catalysts, J. Phys. Chem. B, 2002, 106, p 6921–6929

Y.K. Hsu, Y.C. Chen, and Y.G. Lin, Characteristics and Electrochemical Performances of Lotus-Like CuO/Cu(OH) 2, Hybrid Material Electrodes, J. Electroanal. Chem., 2012, 673, p 43–47

S. Anandan, G.J. Lee, and J.J. Wu, Sonochemical Synthesis of CuO Nanostructures with Different Morphology, Ultrason. Sonochem., 2012, 19, p 682–686

J. Xu, Y. Chang, and Y. Zhang, Effect of Silver Ions on the Structure of ZnO and Photocatalytic Performance of Ag/ZnO Composites, Appl. Surf. Sci., 2008, 255, p 1996–1999

W. Yang, Z. Liu, and D.L. Peng, Room-Temperature Deposition of Transparent Conducting Al-Doped ZnO Films by RF Magnetron Sputtering Method, Appl. Surf. Sci., 2009, 255, p 5669–5673

R. Al-Gaashani, S. Radiman, and A.R. Daud, XPS and Optical Studies of Different Morphologies of ZnO Nanostructures Prepared by Microwave Methods, Ceram. Int., 2013, 39, p 2283–2292

M. Chen, X. Wang, and Y.H. Yu, X-ray Photoelectron Spectroscopy and Auger Electron Spectroscopy Studies of Al-Doped ZnO Films, Appl. Surf. Sci., 2000, 158, p 134–140

G. Ballerini, K. Ogle, and M.G. Barthés-Labrousse, The Acid-Base Properties of the Surface of Native Zinc Oxide Layers: an XPS Study of Adsorption of 1,2-Diaminoethane, Appl. Surf. Sci., 2007, 253, p 6860–6867

Acknowledgments

This research was supported by National Natural Science Foundation of China (Contract numbers (U1534209, 51575459, U1530136, 51627806), supported by Young Scientific Innovation Team of Science and Technology of Sichuan (No. 2017TD0017).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, X., Cai, Z., Liu, S. et al. Influence of Wear Test Parameters on the Electrical Contact Performance of Brass Alloy/Copper Contactors Under Fretting Wear. J. of Materi Eng and Perform 28, 817–827 (2019). https://doi.org/10.1007/s11665-018-3821-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3821-9