Abstract

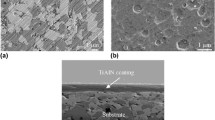

TiAlN/AlCrN coating was deposited on a tungsten carbide insert, using the plasma-enhanced physical vapor deposition (PEPVD) process. The microstructure of the coating was examined and it was found that the TiAlN/AlCrN coating was uniform, highly dense, and less porous. The different phases formed in the coating were analyzed using the x-ray diffraction. The hardness and scratch resistance were measured using the nanoindentation tester and scratch tester, respectively. TiAlN/AlCrN exhibited higher hardness, higher Young’s modulus, and superior scratch resistance when compared to the conventional coatings, such as TiAlN, AlCrN, and TiN. The surface morphology of the coating was characterized using the atomic force microscope (AFM). The surface roughness was found to be lesser in the TiAlN/AlCrN coating. The TiAlN/AlCrN coating has proved to have better corrosion resistance, compared to the uncoated carbide substrate.

Similar content being viewed by others

References

M. Sokovic, Quality Management in Development of Hard Coatings on Cutting Tools, J. Achiev. Mater. Manuf. Eng., 2007, 24(1), p 421–429

L.A. Ivashchenko and G.V. Russakov, Hard Coatings on Cutting Tools, Powder Metall. Met. Ceram., 2004, 43, p 11–12

J.S. Kim, G.J. Kim, M.C. Kang, J.W. Kim, and K.H. Kim, Cutting Performance of Ti-Al-Si-N-Coated Tool by a Hybrid-Coating System for High-Hardened Materials, Surf. Coat. Technol., 2005, 193, p 249–254

S. Veprek and A.S. Argon, Limits to the Strength of Super- and Ultrahard Nanocomposite Coatings, J. Vacuum Sci. Technol., 2003, 21(3), p 532–544

D. Zhu, X. Zhang, and H. Ding, Tool Wear Characteristics in Machining of Nickel-Based Superalloys, Int. J. Mach. Tools Manuf, 2013, 64, p 60–77

A. Knutsson, M.P. Johansson, L. Karlsson, and M. Oden, Thermally Enhanced Mechanical Properties of Arc Evaporated Ti0.34Al0.66N/TiN, J. Appl. Phys., 2010, 108(4), p 312–318

S. Zhang, D. Sun, Y. Fu, and H. Du, Recent Advances of Superhard Nanocomposite Coatings: A Review, Surf. Coat. Technol., 2003, 167, p 113–119

H. Sert, A. Can, K. Habali, and F. Okay, Wear Behavior of PVD TiAlN, CVD TiN Coated and Cermet Cutting Tools, Int. J. Tribol. Ind., 2005, 27(3–4), p 03–09

A.D. Korotaev, D.P. Borisov, and Yu. Moshkov, Nanocomposite and Nanostructured Superhard Ti-Si-B-N Coatings, Russ. Phys. J., 2007, 50(10), p 969–979

Y.-Y. Chang, S.-J. Yang, and D.-Y. Wang., Characterization of TiCr(C, N)/Amorphous Carbon Coatings Synthesized by a Cathodic Arc Deposition Process, J. Thin Solid Films, 2007, 515, p 4722–4726

V. Chawla, A. Chawla, Y. Mehta, D. Puri, S. Prakash, and B.S. Sidhu, Investigation of Properties and Corrosion Behavior of Hard TiAlN and ALCrN PVD Thin Coatings in the 3 wt% NaCl Solution, J. Aust. Ceram. Soc., 2011, 47(1), p 48–55

S. Veprek, S. Mukherjee, H.D. Mannling, and J. He. On the Reliability of the Measurements of Mechanical Properties of Superhard Coatings, J. Mater. Sci. Eng., 2003, A340, p 292–297

G. Matula, Study on Steel Matrix Composites with (Ti,Al)N Gradient PVD Coatings,J. Achiev. Mater. Manuf. Eng., 2006, 34(1), p 79–86

O.A. Tokarev, A.V. Demchyshyn, and G.A. Avtonomov, The Structure and Mechanical Properties of Multilayer Nanocrystalline TiN/ZrN Coatings Obtained by Vacuum-Arc Deposition, Process. Appl. Ceram., 2007, 1(01–02), p 43–47

J.L. Endrino, G.S. Fox-Rabinovich, and C. Gey, Hard AlTiN, AlCrN PVD Coatings for Machining of Austenitic Stainless Steel, Surf. Coat. Technol., 2006, 200, p 6840–6845

Y.C. Chim, X.Z. Ding, X.T. Zeng, and S. Zhang, Oxidation Resistance of TiN, CrN, TiAlN and CrAlN Coatings Deposited by Lateral Rotating Cathode Arc, Int. J. Thin Solid Films, 2010, 517(17), p 4845–4849

G.S. Fox-Rabinovich, K. Yamamoto, M.H. Aguirre, D.G. Cahill, S.C. Veldhuis, A. Biksa, G. Dosbaeva, and L.S. Shuster, Multi-Functional Nano-Multilayered AlTiN/Cu PVD Coating for Machining of Inconel 718 Superalloy, Surf. Coat. Technol., 2010, 204, p 2465–2471

G. Cabrera, F. Torres, J.C. Caicedo, W. Aperador, C. Amaya, and P. Prieto, Improvement of Electrochemical Surface Properties in Steel Substrates Using a Nanostructured CrN/AlN Multilayer Coating, J. Mater. Eng. Perform., 2012, 21, p 128–136

S. Veprek and M.J.G. Veprek-Hejiman, Industrial Applications of Superhard Nanocomposite Coatings, Surf. Coat. Technol., 2008, 202, p 5063–5073

A. Khatibi, J. Sjolen, G. Greczynski, J. Jensen, P. Eklund, and L. Hultman, Structural and Mechanical Properties of Cr-Al-O-N Thin Films Grown by Cathodic Arc Deposition, Acta Mater., 2012, 60, p 6494–6507

J.G. Han, H.S. Myung, H.M. Lee, and L.R. Shaginyan, Microstructure and Mechanical Properties of Ti-Ag-N and Ti-Cr-N Superhard Nanostructured Coatings, Surf. Coat. Technol., 2003, 174–175, p 738–743

P. Zeman, R. Cerstvy, P.H. Mayrhofer, C. Mitterer, and J. Musil, Structure and Properties of Hard and Superhard Zr-Cu-N Nanocomposite Coatings, Mater. Sci. Eng., 2000, A289, p 189–197

Y.-Y. Chang, D.Y. Wang, and C.-Y. Hung, Structural and Mechanical Properties of Nanolayered TiAlN/CrN Coatings Synthesized by a Cathodic Arc Deposition Process, Surf. Coat. Technol., 2005, 200, p 1702–1708

H.S. Myung, H.M. Lee, L.R. Shaginyan, and J.G. Han, Microstructure and Mechanical Properties of Cu Doped TiN Superhard Nanocomposite Coatings, Surf. Coat. Technol., 2003, 163–164, p 591–596

A.C. Fischer-Cripps, Critical Review of Analysis and Interpretation of Nanoindentation Test Data, Surf. Coat. Technol., 2006, 200, p 4153–4165

S. Veprek, A. Niederhofer, K. Moto, T. Bolom, H.D. Mannling, P. Nesladek, G. Dollinger, and A. Bergmaier, Composition, Nanostructured and Origin of the Ultrahardness in nc-TiN/a-Si3 N4/a – and nc-TiSi2 Nanocomposites with Hv = 80 to >105 GPa, Surf. Coat. Technol., 2000, 133–134, p 152–159

S. Veprek and A.S. Argon, Mechanical Properties of Superhard Composites, Surf. Coat. Technol., 2001, 146–147, p 175–182

S. Veprek, P. Nesladek, A. Niederhofer, F. Glatz, M. Jilek, and M. Sima, Recent Progress in the Superhard Nanocrystalline Composite: Towards Their Industrialization and Understanding of the Origin of the Superhardness, Surf. Coat. Technol., 1998, 108–109, p 138–147

J. Musil, F. Kunc, H. Zeman, and H. Polakova, Relationships Between Hardness, Young’s and Elastic Recovery in Hard Nanocomposite Coatings, Surf. Coat. Technol., 2002, 154, p 304–313

A. Niederhofer, P. Nesladek, H.D. Mannling, K. Moto, S. Veprek, and M. Jilek, Structural Properties, Internal Stress and Thermal Stability of nc-TiN/a-Si3N4, nc-TiN/TiSix and nc-(Ti1−yAlySix)N Superhard Nanocomposite Coatings Reaching the Hardness of Diamond, Surf. Coat. Technol., 1999, 120–121, p 173–178

N. Panich, P. Wangyao, N. Vattanaprateep, and S. Yong, Techniques to Improve Coating Adhesion of Superhard Coatings, J. Met. Mater. Miner., 2006, 16(2), p 19–23

J. Stallard, S. Poulat, and D.G. Teer, The Study of the Adhesion of a TiN Coating on Steel and Titanium Alloy Substrates Using a Multi-Mode Scratch Tester, Tribol. Int., 2006, 39, p 159–166

Y. **e and H.M. Hawthorne, A Model for Compressive Coating Stresses in the Scratch Adhesion Test, Surf. Coat. Technol., 2001, 141, p 25–154

X. Pang, K. Gao, F. Luo, Y. Emirov, A.A. Levin, and A.A. Volinsky, Investigation of Microstructure and Mechanical Properties of Multi-Layer Cr/Cr2O3 Coatings, Thin Solid Films, 2009, 517, p 922–1927

L.A. Dobrzanski, S. Skrzypek, D. Pakula, J. Mikula, and A. Kriz, Influence of the PVD and CVD Technologies on the Residual Macro Stresses and Functional Properties of the Coated Tool Ceramics, J. Achiev. Mater. Manuf. Eng., 2009, 35(2), p 162–168

M. Hagarova, Experimental Methods of Assessment of PVD Coatings Properties, J. Met. Mater. Miner., 2007, 17(2), p 29–35

C.-L. Chang, C.-S. Huang, and J.-Y. Jao, Microstructural, Mechanical and Wear Properties of Cr-Al-B-N Coatings Deposited by DC Reactive Magnetron Co-Sputtering, Surf. Coat. Technol., 2011, 205, p 2730–2737

G. Zhang, T. Fan, T. Wang, and H. Chen, Microstructure, Mechanical and Tribological Behavior of MoN x /SiN x Multilayer Coatings Prepared by Magnetron Sputtering, Appl. Surf. Sci., 2013, 274, p 231–236

C.J. Tavares, L. Rebouta, E. Alves, A. Cavaleiro, P. Goudeau, and J.P. Riviere, A Structural and Mechanical Analysis on PVD-Grown (Ti, Al)N/Mo Multilayers, Thin Solid Films, 2000, 377–378, p 425–429

P.V. Zinin, V.L. Solozhenko, A.J. Malkin, and L.C. Ming, Atomic Force Microscopy Studies of Cubic BC2N, A New Superhard Phase, J. Mater. Sci., 2005, 40, p 3009–3011

H.C. Barshilia, B. Deepthi, K.S. Rajam, K.P. Bhatti, and S. Chaudhary, Growth and Characterization of TiAlNCrAlN Superlattices Prepared by Reactive Direct Current Magnetron Sputtering, J. Vacuum Sci. Technol. A, 2009, 27(1), p 29–36

H.C. Barshilia, M.S. Prakash, A. Jain, and K.S. Rajam, Structure, Hardness and Thermal Stability of TiAlN and Nanolayered TiAlN/CrN Multilayer Films, Vacuum, 2005, 77(2), p 169–179

P. Lima, M. Araujo, M.T. Mathew, L.A. Rocha, A.M. Pinto, J.M. Chappe, M.D. Ramos, L. Marques, J.F. Pierson, and F. Vaz, Tribocorrosion Behavior of Ti–C– O-N Nanostructured Thin Films (Black) for Decorative Applications, Tribol. Int., 2013, 68, p 01–10

R. Ananthakumar, B. Subramanian, A. Kobayashi, and M. Jayachandran, Electrochemical Corrosion and Materials Properties of Reactively Sputtered TiN/TiAlN Multilayer Coatings, Ceram. Int., 2012, 38, p 477–485

V. Braic, M. Balaceanu, M. Braic, A. Vladescu, S. Panseri, and A. Russo, Characterization of Multi-Principal-Element (TiZrNbHfTa)N and (TiZrNbHfTa)C Coatings for Biomedical Applications, J. Mech. Behav. Biomed. Mater., 2012, 1, p 197–205

Acknowledgments

The authors wish to express their thanks to Oerlikon balzers coating India Ltd., Irrungattukottai, NAL-Bangalore and Sathyabama University, for providing the facilities to carry out these studies and to prepare this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sampath Kumar, T., Balasivanandha Prabu, S. & Manivasagam, G. Metallurgical Characteristics of TiAlN/AlCrN Coating Synthesized by the PVD Process on a Cutting Insert. J. of Materi Eng and Perform 23, 2877–2884 (2014). https://doi.org/10.1007/s11665-014-1057-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1057-x