Abstract

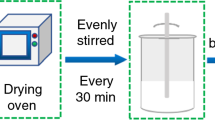

The application of stearic acid in the latent thermal energy storage (LTES) systems is hindered due to its lower heat transfer rate. Stearic acid (SA) was blended with copper foam (CF) of pore numbers per inch (PPI) of 5, 20, and 40 to prepare composite phase change materials via a molten impregnation method. The thermal physical properties including latent heat, phase change temperature, and thermal energy storage density of composites were characterized. The thermogravimetric analysis indicated that the loadages of SA of SA/CF(5 PPI), SA/CF(20 PPI), and SA/CF(40 PPI) were 74.69%, 71.03%, and 63.54%, respectively; The latent heat of SA/CF(5 PPI), SA/CF(20 PPI), and SA/CF(40 PPI) were determined to 139.9 J-g-1, 132.7 J-g-1, and 117.8 J-g-1, respectively. Meanwhile, the infrared thermal images of SA and SA/CF composites were provided to demonstrate the thermal energy storage and dissipation capability intuitively by the temperature response and surface temperature distribution. The infrared thermal images indicated the addition of CF also reduced the fluidity of liquid SA, and the SA/CF(40 PPI) had better internal heat transfer uniformity and thermal diffusion performance than SA/CF(5 PPI) and SA/CF(20 PPI). All these thermal properties suggested SA/CF(40 PPI) has the potential application in the latent thermal energy storage.

Similar content being viewed by others

References

Zhang N., Yuan Y., Cao X., Du Y., Zhang Z., Gui Y., Latent heat thermal energy storage systems with solid-liquid phase change materials: A review. Advanced Engineering Materials, 2018, 20: 1700753.

Li C., **e B., Chen D., Chen J., Li W., Chen Z., Gibb S.W., Long Y., Ultrathin graphite sheets stabilized stearic acid as a composite phase change material for thermal energy storage. Energy, 2019, 166: 246–255.

Alva G., Liu L., Huang X., Fang G., Thermal energy storage materials and systems for solar energy applications. Renewable and Sustainable Energy Reviews, 2017, 68: 693–706.

Liu S., Han J., Gao Q., Kang W., Ren R., Wang L., Chen D., Wu D., Laurie acid/bentonite/flake graphite composite as form-stable phase change materials for thermal energy storage. Materials Express, 2020, 10: 214–224.

Li C., Wang M., **e B., Ma H., Chen J., Enhanced properties of diatomite-based composite phase change materials for thermal energy storage. Renewable Energy, 2020, 147: 265–274.

Li C., Zhang B., **e B., Zhao X., Chen J., Tailored phase change behavior of Na2SO4T0H2O/expanded graphite composite for thermal energy storage. Energy Conversion and Management, 2020, 208: 112586.

Gao X., Yuan Y., Cao X., Wu H., Zhao X., Yan D., Coupled cooling method and application of latent heat thermal energy storage combined with pre-cooling of envelope: Temperature control using phase-change chair. Sustainable Cities and Society, 2018, 42: 38–51.

An Z., Jia L., Ding Y., Dang C., Li X., A review on lithium-ion power battery thermal management technologies and thermal safety. Journal of Thermal Science, 2017, 26: 391–412.

Li C., Zhang B., **e B., Zhao X., Chen J., Chen Z., Long Y., Stearic acid/expanded graphite as a composite phase change thermal energy storage material for tankless solar water heater. Sustainable Cities and Society, 2019, 44: 458–464.

Soni V., Kumar A., Jain V.K., Performance evaluation of nano-enhanced phase change materials during discharge stage in waste heat recovery. Renewable Energy, 2018, 127: 587–601.

**a M., Yuan Y., Zhao X., Cao X., Tang Z., Cold storage condensation heat recovery system with a novel composite phase change material. Applied Energy, 2016, 175: 259–268.

Romani J., Belusko M., Alemu A., Cabeza L.F., de Gracia A., Bruno E., Control concepts of a radiant wall working as thermal energy storage for peak load shifting of a heat pump coupled to a PV array. Renewable Energy, 2018, 118: 489–501.

Pereira da Cunha J., Eames P., Thermal energy storage for low and medium temperature applications using phase change materials - A review. Applied Energy, 2016, 177: 227–238.

Naplocha K., Dmitruk A., Kaczmar J., Lichota J., Smykowski D., Effects of cellular metals on the performances and durability of composite heat storage systems. International Journal of Heat and Mass Transfer, 2017, 114: 1214–1219.

Sivasamy P., Devaraju A., Harikrishnan S., Review on heat transfer enhancement of phase change materials (PCMs). Materials Today: Proceedings, 2018, 5: 14423–14431.

Cardenas B., Leon N., High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques. Renewable and Sustainable Energy Reviews, 2013, 27: 724–737.

Zhang Q., Wang H., Ling Z., Fang X., Zhang Z., RT100/expand graphite composite phase change material with excellent structure stability, photo-thermal performance and good thermal reliability. Solar Energy Materials and Solar Cells, 2015, 140: 158–166.

Ye S., Zhang Q., Hu D., Feng J., Core-shell-like structured graphene aerogel encapsulating paraffin: shape-stable phase change material for thermal energy storage. Journal of Materials Chemistry A, 2015, 3: 4018–4025.

Shang B., Hu J., Hu R., Cheng J., Luo X., Modularized thermal storage unit of metal foam/paraffin composite. International Journal of Heat and Mass Transfer, 2018, 125: 596–603.

Tauseef ur R., Ali H.M., Janjua M.M., Sajjad U., Yan W.-M., A critical review on heat transfer augmentation of phase change materials embedded with porous materials/foams. International Journal of Heat and Mass Transfer, 2019, 135: 649–673.

Darzi M.E., Golestaneh S.I., Kamali M., Karimi G., Thermal and electrical performance analysis of co-electrospun-electrosprayed PCM nanofiber composites in the presence of graphene and carbon fiber powder. Renewable Energy, 2019, 135: 719–728.

Gimenez P., Jove A., Prieto C., Fereres S., Effect of an increased thermal contact resistance in a salt PCM-graphite foam composite TES system. Renewable Energy, 2017, 106: 321–334.

Hsu T.H., Chung C.H., Chung F.J., Chang C.C., Lu M.C., Chueh Y.L., Thermal hysteresis in phase-change materials: Encapsulated metal alloy core-shell microparticles. Nano Energy, 2018, 51: 563–570.

Zhu Y., Chi Y., Liang S., Luo X., Chen K., Tian C., Wang J., Zhang L., Novel metal coated nanoencapsulated phase change materials with high thermal conductivity for thermal energy storage. Solar Energy Materials and Solar Cells, 2018, 176: 212–221.

Qureshi Z.A., Ali H.M., Khushnood S., Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: A review. International Journal of Heat and Mass Transfer, 2018, 127: 838–856.

Roller M., Walter H., Hameter M., Transient numerical simulation of the melting and solidification behavior of NaNO3 using a wire matrix for enhancing the heat transfer. Energies, 2016, 9: 205.

Johnson M., Vogel J., Hempel M., Hachmann B., Dengel A., Design of high temperature thermal energy storage for high power levels. Sustainable Cities and Society, 2017, 35: 758–763.

Ali H.M., Arshad A., Experimental investigation of n-eicosane based circular pin-fin heat sinks for passive cooling of electronic devices. International Journal of Heat and Mass Transfer, 2017, 112: 649–661.

Song X., Thermal analysis of metal foam matrix composite phase change material. Journal of Thermal Science, 2015, 24: 386–390.

Mustaffar A., Harvey A., Reay D., Melting of phase change material assisted by expanded metal mesh. Applied Thermal Engineering, 2015, 90: 1052–1060.

Tian H., Du L., Wei X., Deng S., Wang W., Ding J., Enhanced thermal conductivity of ternary carbonate salt phase change material with Mg particles for solar thermal energy storage. Applied Energy, 2017, 204: 525–530.

Gimenez-Gavarrell P., Fereres S., Glass encapsulated phase change materials for high temperature thermal energy storage. Renewable Energy, 2017, 107: 497–507.

Cao X., Yuan Y., **ang B., Sun L., **ngxing Z., Numerical investigation on optimal number of longitudinal fins in horizontal annular phase change unit at different wall temperatures. Energy and Buildings, 2018, 158: 384–392.

Arshad A., Ali H.M., Khushnood S., Jabbal M., Experimental investigation of PCM based round pin-fin heat sinks for thermal management of electronics: Effect of pin-fin diameter. International Journal of Heat and Mass Transfer, 2018, 117: 861–872.

Li T.X., Wu D.L., He E., Wang R.Z., Experimental investigation on copper foam/hydrated salt composite phase change material for thermal energy storage. International Journal of Heat and Mass Transfer, 2017, 115: 148–157.

Wang C., Lin T., Li N., Zheng H., Heat transfer enhancement of phase change composite material: Copper foam/paraffin. Renewable Energy, 2016, 96: 960–965.

Rehman T.-U., Ali H.M., Saieed A., Pao W., Ali M., Copper foam/PCMs based heat sinks: An experimental study for electronic cooling systems. International Journal of Heat and Mass Transfer, 2018, 127: 381–393.

Wang Z., Zhang Z., Jia L., Yang L., Paraffin and paraffin/aluminum foam composite phase change material heat storage experimental study based on thermal management of Li-ion battery. Applied Thermal Engineering, 2015, 78: 428–436.

Zhao C.Y., Wu Z.G., Heat transfer enhancement of high temperature thermal energy storage using metal foams and expanded graphite. Solar Energy Materials & Solar Cells, 2011, 95: 636–643.

Zhao C.Y., Zhou D., Wu Z.G., Heat transfer of phase change materials (PCMs) in porous materials. Frontiers inEnergy, 2011, 5: 174.

Xu Y., Zhu G., Lv S., Shan B., He Y., Preparation and thermal properties of metal-based composite phase change material for high temperature thermal energy storage. Journal of Engineering Thermophysics, 2016, 37: 1371–1376.

Li C., **e B., He Z., Chen J., Long Y., 3D structure fungi-derived carbon stabilized stearic acid as a composite phase change material for thermal energy storage. Renewable Energy, 2019, 140: 862–873.

Wang C., Zheng J., Yu Y., Influence of pore distribution on heat transfer characteristics of fractal foam metal based phase change materials. Chemical Industry and Engineering Progress, 2018, 37: 3540–3546.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51874047, 51504041); the Changsha City Fund for Distinguished and Innovative Young Scholars (kq1802007); the Fund for University Young Core Instructors of Hunan Province, China; the Outstanding Youth Project of Hunan Provincial Department of Education, China (18B148); the Innovation Program for Postgraduate of Hunan Province, China (CX20190688); and the Hunan Province 2011 Collaborative Innovation Center of Clean Energy and Smart Grid.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Zhao, X., Zhang, B. et al. Stearic Acid/Copper Foam as Composite Phase Change Materials for Thermal Energy Storage. J. Therm. Sci. 29, 492–502 (2020). https://doi.org/10.1007/s11630-020-1272-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-020-1272-8