Abstract

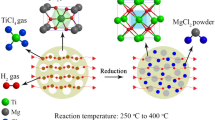

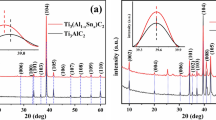

Titanium aluminum carbide (Ti3AlC2 and Ti2AlC) powders were synthesized from TiH2 powders instead of Ti powders as Ti source by a tube furnace under argon atmosphere without preliminary dehydrogenation. 95 wt% pure Ti3AlC2 powders were synthesized from TiH2/1.1Al/2TiC at 1 450 °C for 120 min. High-purity Ti2AlC powders were also prepared from 3TiH2/1.5Al/C and 2TiH2/1.5Al/TiC powders at 1 400 °C for 120 min. The as-synthesized samples were porous and easy to be ground into powders. Sn or Si additives in starting materials increased the purity of synthesized Ti3AlC2 obviously and expanded the temperature range for the synthesis of Ti3AlC2. With Si or Sn as additives, high pure Ti3AlC2 was synthesized at 1 200 °C for 60 min from TiH2/x Si/Al/2TiC and TiH2/x Sn/Al/2TiC (x = 0.1, 0.2), respectively.

Similar content being viewed by others

References

N V Tzenov, M W Barsoum. Synthesis and Characterization of Ti3AlC2 [J]. J. Am. Ceram. Soc., 2000, 83(4): 825–832

A G Zhou, C A Wang, Y Huang. A Possible Mechanism on Synthesis of Ti3AlC2 [J]. Mater. Sci. Eng. A, 2003, 352(1–2): 333–339

Y Bao, J Chen, X Wang, et al. Shear Strength and Shear Failure of Layered Machinable Ti3AlC2 Ceramics [J]. J. Eur. Ceram. Soc., 2004, 24(5): 855–860

M Pietzka, J Schuster. Summary of Constitution Data of the System Al-C-Ti [J]. J. Phase Equilib., 1994, 15(4): 392–400

P Wang, B Mei, X Hong, et al. Fabrication of Ti2AlC by Spark Plasma Sintering from Elemental Powders and Thermodynamics Analysis of Ti-Al-C System [J]. J. Wuhan Univ. Tech. -Mater. Sci. Ed., 2007, 22(2): 325–328

B Mei, X Hong, J Zhu, et al. Gradient Structure of Ti-Al-C Ternary Carbide Prepared by Hot-Pressing Sintering [J]. J. Wuhan Univ. Tech.-Mater. Sci. Ed., 2005, 20(2): 5–7

C Peng, C A Wang, Y Song, et al. A Novel Simple Method to Stably Synthesize Ti3AlC2 Powder with High Purity [J]. Mater. Sci. Eng., A, 2006, 428(1–2): 54–58

J Song, H Yang. Fabrication of High-Purity Ternary Carbide Ti3AlC2 by Spark Plasma Sintering (SPS) Technique [J]. J. Wuhan Univ. Tech.-Mater. Sci. Ed., 2008, 23(2): 177–180

C L Yeh, Y G Shen. Combustion Synthesis of Ti3AlC2 from Ti/Al/C/ TiC Powder Compacts [J]. J. Alloys Compd., 2008, 466(1–2): 308–313

Y Zou, Z Sun, S Tada, et al. Rapid Synthesis of Single-Phase Ti3AlC2 Through Pulse Discharge Sintering a TiH2/Al/TiC Powder Mixture [J]. Scripta Mater., 2007, 56(9): 725–728

Y Zou, Z M Sun, H Hashimoto, et al. Synthesis Reactions For Ti3AlC2 Through Pulse Discharge Sintering TiH2/Al/C Powder Mixture [J]. J. Alloys Compd., 2009, 468(1-2): 217–221

S Amini, M W Barsoum. On the Effect of Texture on the Mechanical and Dam** Properties of Nanocrystalline Mg-Matrix Composites Reinforced with MAX Phases[J]. Mater. Sci. Eng. A, 2010, 527(16–17): 3 707–3 718

B Liang, M Wang, J Sun, et al. Preparation of Ti3AlC2 by Mechanically Activated Sintering with Sn Aids [J]. Int. J. Refract. Met. Hard Mater., 2009, 27(5): 927–930

X Yin, M Li, T Li, et al. Diffusion Bonding of Ti3AlC2 Ceramic via a Si Interlayer[J]. J. Mater. Sci., 2007, 42(17): 7 081–7 085

X Min, Y Ren. Electronic Structures and Bonding Properties of Ti2AlC and Ti3AlC2 [J]. J. Wuhan Univ. Tech.-Mater. Sci. Ed., 2007, 22(1): 27–30

V Bhosle, E Baburaj, M Miranova, et al. Dehydrogenation of TiH2 [J]. Mater. Sci. Eng., A, 2003, 356(1–2): 190–199

C A Wang, A Zhou, L Qi, et al. Quantitative Phase Analysis in the Ti-Al-C Ternary System by X-Ray Diffraction [J]. Powder Diffr., 2005, 20(3): 218–223

Y L Chen, M Yan, Y M Sun, et al. The Phase Transformation and Microstructure of TiAl/Ti2AlC Composites Caused by Hot Pressing [J]. Ceram. International, 2009, 35(5): 1 807–1 812

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by National Natural Science Foundation of China (Nos. 51002045, 51205111), Program for Innovative Research Team (in Science and Technology) in the University of Henan Province (No.2012IRTSTHN007), IRTHPU (No.T2013-4), and Opening Project of Henan Key Discipline Open Laboratory of Mining Engineering Materials (No.MEM12-5)

Rights and permissions

About this article

Cite this article

Li, L., Zhou, A., Xu, L. et al. Synthesis of high pure Ti3AlC2 and Ti2AlC powders from TiH2 powders as Ti source by tube furnace. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 28, 882–887 (2013). https://doi.org/10.1007/s11595-013-0786-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-013-0786-2