Abstract

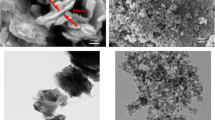

The tribological properties of combinative addition of nano-MoS2 and nano-SiO2 to the base oil have been investigated with a reciprocating ball-on-plate tribotester for magnesium alloy–steel contacts. The results demonstrate that the optimum mass ratio of nano-SiO2 to nano-MoS2 is 0.25:0.75. The optimum combinative addition into the base oil reduces the friction coefficient by 43.8% and the surface roughness (Sa) by 31.7% when compared to that found with the base oil. Meanwhile, the combinative addition of nano-MoS2 and nano-SiO2, in comparison with single nanoparticles addition, is more pronounced in terms of the lubrication film stability. The excellent tribological properties of the SiO2/MoS2 combinations are attributed to the formation of physical adsorption films and tribochemical products during the rubbing process and the micro-cooperation of various nanoparticles with different shapes and lubrication mechanisms.

Similar content being viewed by others

References

Selda Ucuncuoglu A E, Secgin G O, Duygulu O. Effect of asymmetric rolling proce ss on the microstructure, mechanical properties and texture of AZ31 magnesium alloys sheets produced by twin roll casting technique. J Magnes Alloy, 2014, 2: 92–98

Suh J, Victoria-Hernandez J, Letzig D, et al. Improvement in cold formability of AZ31 magnesium alloy sheets processed by equal channel angular pressing. J Mater Process Tech, 2015, 217: 286–293

Griffiths D. Explaining texture weakening and improved formability in magnesium rare earth alloys. Mater Sci Technol, 2015, 31: 10–24

Avvari M, Narendranath S. Influence of Route-R on wrought magnesium AZ61 alloy mechanical properties through equal channel angular pressing. J Magnes Alloy, 2014, 2: 159–164

Zhang Q, **ao F, Guo H, et al. Warm negative incremental forming of magnesium alloy AZ31 Sheet: New lubricating method. J Mater Process Tech, 2010, 210: 323–329

Heinrichs J, Jacobson S. Laboratory test simulation of aluminium cold forming–influence from PVD tool coatings on the tendency to galling. Surf Coat Tech, 2010, 204: 3606–3613

Peng D X, Kang Y, Hwang R M, et al. Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol Int, 2009, 42: 911–917

Jia Z F, Wang P, **a Y Q, et al. Tribological behaviors of diamond-like carbon coatings on plasma nitrided steel using three BN-containing lubricants. Appl Surf Sci, 2009, 255: 6666–6674

Huang W J, Du C H, Li Z F, et al. Tribological characteristics of magnesium alloy using N-containing compounds as lubricating additives during sliding. Wear, 2006, 260: 140–148

Huang W J, Fu Y, Wang J, et al. Effect of chemical structure of borates on the tribological characteristics of magnesium alloy during sliding. Tribol Int, 2005, 38: 775–780

**a Y Q, Jia Z F, Jia J H. Advanced Tribology. Berlin: Springer Berlin Heidelberg, 2010

Tang Z L, Li S H. A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr Opin Solid ST M, 2014, 18: 119–139

Li Z P, Li X F, Zhang Y W, et al. Tribological study of a highly hydrolytically stable phenylboronic acid ester containing benzothiazolyl in mineral oil. Appl Surf Sci, 2014, 308: 91–99

Somers A E, Khemchandani B, Howlett P C, et al. Ionic liquids as antiwear additives in base oils: influence of structure on miscibility and antiwear performance for steel on aluminum. ACS Appl Mater Inter, 2013, 5: 11544–11553

Ratoi M, Niste V B, Walker J, et al. Mechanism of action of WS2 lubricant nanoadditives in high-pressure contacts. Tribol Lett, 2013, 52: 81–91

Nan F, Xu Y, Xu B S, et al. Effect of natural attapulgite powders as lubrication additive on the friction and wear performance of a steel tribo-pair. Appl Surf Sci, 2014, 307: 86–91

Aldana P U, Vacher B, Le Mogne T, et al. Action mechanism of WS2 nanoparticles with ZDDP additive in boundary lubrication regime. Tribol Lett, 2014, 56: 249–258

Hu K H, Liu M, Wang Q J, et al. Tribological properties of molybdenum disulfide nanosheets by monolayer restacking process as additive in liquid paraffin. Tribol Int, 2009, 42: 33–39

Kogovšek J, Remškar M, Mrzel A, et al. Influence of surface roughness and running-in on the lubrication of steel surfaces with oil containing MoS2 nanotubes in all lubrication regimes. Tribol Int, 2013, 61: 40–47

Mosleh M, Atnafu N D, Belk J H, et al. Modification of sheet metal forming fluids with dispersed nanoparticles for improved lubrication. Wear, 2009, 267: 1220–1225

Kalin M, Kogovšek J, Kovac J, et al. The formation of tribofilms of MoS2 nanotubes on steel and DLC-Coated surfaces. Tribol Lett, 2014, 55: 381–291

Kogovšek J, Remškar M, Kalin M. Lubrication of DLC-coated surfaces with MoS2 nanotubes in all lubrication regimes: Surface roughness and running-in effects. Wear, 2013, 303: 361–370

Sayuti M, Erh O M, Sarhan A A D, et al. Investigation on the morphology of the machined surface in end milling of aerospace AL6061-T6 for novel uses of SiO2 nanolubrication system. J Clean Prod, 2014, 66: 655–663

Sayuti M, Sarhan A A, Hamdi M. An investigation of optimum SiO2 nanolubrication parameters in end milling of aerospace Al6061-T6 alloy. Int J Adv Manuf Technol, 2013, 67: 833–849

Sia S Y, Sarhan A A D. Morphology investigation of worn bearing surfaces using SiO2 nanolubrication system. Int J Adv Manuf Technol, 2013, 70: 1063–1071

Qu J, Bansal D G, Yu B, et al. Antiwear performance and mechanism of an oil-miscible ionic liquid as a lubricant additive. ACS Appl Mater Inter, 2012, 4: 997–1002

Hu K H, Hu X G, Xu Y F, et al. The effect of morphology on the tribological properties of MoS2 in liquid paraffin. Tribol Lett, 2010, 40: 155–165

Tannous J, Dassenoy F, Lahouij I, et al. Understanding the tribochemical mechanisms of IF-MoS2 nanoparticles under boundary lubrication. Tribol Lett, 2011, 41: 55–64

Koroteev V O, Bykysgeva L G, Okotrub A V, et al. Formation of MoS2 nanoparticles on the surface of reduced graphite oxide. Phys Status Solidi B, 2011, 248: 2740–2743

Han X H, Wang A J, Wang X S, et al. Catalytic performance of P-modified MoO3/SiO2 in oxidative desulfurization by cumene hydroperoxide. Catal Commun, 2013, 42: 6–9

Rabaso P, Ville F, Dassenoy F, et al. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear, 2014, 320: 161–178

Li X H, Cao Z, Zhang Z J, et al. Surface-modification in situ of nano-SiO2 and its structure and tribological properties. Appl Surf Sci, 2006, 252: 7856–7861

Hu K H, Huang F, Hu X G, et al. Synergistic effect of nano-MoS2 and anatase nano-TiO2 on the lubrication properties of MoS2/TiO2 nano-clusters. Tribol Lett, 2011, 43: 77–87

Tannous J, Dassenoy F, Lahouij I, et al. Understanding the tribochemical mechanisms of IF-MoS2 nanoparticles under boundary lubrication. Tribol Lett, 2011, 41: 55–64

Sia S Y, Sarhan A A D. Morphology investigation of worn bearing surfaces using SiO2 nanolubrication system. Int J Adv Manuf Technol, 2014, 70: 1063–1071

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

**e, H., Jiang, B., Wang, Q. et al. Effects of combined additions of SiO2 and MoS2 nanoparticles as lubricant additive on the tribological properties of AZ31 magnesium alloy. Sci. China Technol. Sci. 59, 689–698 (2016). https://doi.org/10.1007/s11431-015-5990-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-015-5990-1