Abstract

Cement is an essential material used in constructional activities. An emerging concern in the industry however is the CO2 emissions, which are triggered by cement manufacturing units. These emissions can be controlled to some extent by not using cement exclusively and instead replacing a percentage of it with waste material with properties similar to cement. Electric arc furnace dust (EAFD) and rice straw ash (RSA) are waste materials from industrial and agricultural sources which also contain similar constituents that are present in cement. Thus, the objective of this study is to check the effect of EAFD and RSA on concrete properties with the application of Aspergillus niger and Bacillus megaterium. Taguchi’s design of experiments has been utilised to explore the effect of operating parameters (i.e. EAFD and RSA replacement (5%, 10% and 15%), curing period of concrete cubes (7, 14 and 28 days) and cell count of fungus/bacteria (104, 106 and 108 CFU/ml)) on the compressive strength and water absorption capacity of concrete blocks in three different scenarios. Optimisation has then been carried out by using the multi-objective genetic algorithm to evaluate the maximum performance of concrete. However, the results of the study indicate best performance in the 2nd context where dust replacement, curing time and cell count were 5%, 18 days and 9.39 × 107 cells per ml of water, respectively, for concrete production utilising Aspergillus niger.

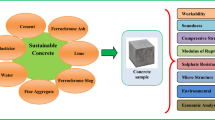

Graphical abstract

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article.

References

Abbass W, Khan MI, Mourad S (2018) Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr Build Mater 168:556–569. https://doi.org/10.1016/j.conbuildmat.2018.02.164

Al-Zaid RZ, Al-Sugair FH, Al-Negheimish AI (1997) Investigation of potential uses of electric-arc furnace dust (EAFD) in concrete. Cem Concr Res 27:267–278. https://doi.org/10.1016/S0008-8846(96)00204-9

Anastasiadou K, Christopoulos K, Mousios E, Gidarakos E (2011) Solidification/stabilization of fly and bottom ash from medical waste incineration facility. J Hazard Mater 207–208:165–170. https://doi.org/10.1016/j.jhazmat.2011.05.027

ASTM C 642 (2006) Standard test method for density, absorption, and voids in hardened concrete. ASTM Int West Conshohocken, PA 1–3

Banerjee G, Chakraborty R (2005) Management of arsenic-laden water plant sludge by stabilization. Clean Technol Environ Policy 7:270–278. https://doi.org/10.1007/s10098-005-0275-1

Bhaskar S, Anwar Hossain KM, Lachemi M, Wolfaardt G, Otini Kroukamp M (2017) Effect of self-healing on strength and durability of zeolite-immobilized bacterial cementitious mortar composites. Cem Concr Compos 11:151–162. https://doi.org/10.1016/j.cemconcomp.2017.05.013

Bildirici ME (2019) Cement production, environmental pollution, and economic growth: evidence from China and USA. Clean Technol Environ Policy 21:783–793. https://doi.org/10.1007/s10098-019-01667-3

Biswas L (2019) 7 Physical test of cement to justify its quality. In: Build. Mater. https://www.acivilengineer.com/cement-test/. Accessed 12 Mar 2020

Burgstaller W, Schinner F (1993) Leaching of metals with fungi. J Biotechnol 27:91–116

Cardoso C, Camões A, Eires R, Mota A, Araújo J, Castro F, Carvalho J (2018) Using foundry slag of ferrous metals as fine aggregate for concrete. Resour Conserv Recycl 138:130–141. https://doi.org/10.1016/j.resconrec.2018.05.020

Chahal N, Siddique R, Rajor A (2012) Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr Build Mater 28:351–356. https://doi.org/10.1016/j.conbuildmat.2011.07.042

da Silva Magalhães M, Faleschini F, Pellegrino C, Brunelli K (2017) Cementing efficiency of electric arc furnace dust in mortars. Constr Build Mater 157:141–150. https://doi.org/10.1016/j.conbuildmat.2017.09.074

Dauvalter VA (1998) Heavy metals in the bottom sediments of the Inari–Pasvik Lake – river system. Water Resour 25:451–457

Dhanya S, Soman K, Smitha MDMS et al (2016) Strength and water absorption of bacterial concrete prepared with M.sand – a study. Int J Eng Res Technol V5:354–356. https://doi.org/10.17577/ijertv5is090346

Dunuweera SP, Rajapakse RMG (2018) Cement types, composition, uses and advantages of nanocement, environmental impact on cement production, and possible solutions. Adv Mater Sci Eng 2018:1–11. https://doi.org/10.1155/2018/4158682

El Dieb AS, Kanaan DM (2018) Ceramic waste powder an alternative cement replacement – characterization and evaluation. Sustain Mater Technol 17:e00063. https://doi.org/10.1016/j.susmat.2018.e00063

Elinwa AU, Ejeh SP (2004) Effects of the incorporation of sawdust waste incineration fly ash in cement pastes and mortars. J Asian Archit Build Eng 3:1–7. https://doi.org/10.3130/jaabe.3.1

El-Sayed MA, El-Samni TM (2006) Physical and chemical properties of rice straw ash and its effect on the cement paste produced from different cement types. J King Saud Univ - Eng Sci 19:21–29. https://doi.org/10.1016/S1018-3639(18)30845-6

Falade F, Ikponmwosa E, Fapohunda C (2012) Potential of pulverized bone as a pozzolanic material. Int J Sci Eng Res 3:1–6

Filipponi P, Polettini A, Pomi R, Sirini P (2003) Physical and mechanical properties of cement-based products containing incineration bottom ash. Waste Manag 23:145–156. https://doi.org/10.1016/S0956-053X(02)00041-7

Ghosh S, Biswas M, Chattopadhyay BD, Mandal S (2009) Microbial activity on the microstructure of bacteria modified mortar. Cem Concr Compos 31:93–98. https://doi.org/10.1016/j.cemconcomp.2009.01.001

Guézennec AG, Huber JC, Patisson F, Sessiecq P, Birat JP, Ablitzer D (2005) Dust formation in electric arc furnace: birth of the particles. Powder Technol 157:2–11. https://doi.org/10.1016/j.powtec.2005.05.006

Hseu Z-Y, Chen Z-S, Tsai C-C, Tsui CC, Cheng SF, Liu CL, Lin HT (2002) Digestion methods for total heavy metals in sediments and soils. Water Air Soil Pollut 141:189–205. https://doi.org/10.1023/A:1021302405128

Hutton M (1987) Human health concerns of lead, mercury, cadmium and arsenic. Lead Mercur Cadmium Arsen Environ 31:53–68

IS 10262 (2009) Guidelines for concrete mix design proportioning. Bur Indian Stand Delhi:1–21

IS 383 (1970) Aggregates, specifications for fine aggregates and coarse concrete, plain and reinforced. Specif coarse fine aggregates from Nat sources Concr:1–24

IS 456 (2000) Concrete, plain and reinforced. Bureau of Indian Standards, New Delhi

IS 516 (1959) Method of tests for strength of concrete. Indian Stand:1–30

IS:8112 (2013) Ordinary Portland Cement, 43 Grade - specification. Bureau of Indian Standards,New Delhi, New Delhi

Kaur G, Siddique R, Rajor A (2013) Micro-structural and metal leachate analysis of concrete made with fungal treated waste foundry sand. Constr Build Mater 38:94–100. https://doi.org/10.1016/j.conbuildmat.2012.07.112

Kavak D (2013) Removal of lead from aqueous solutions by precipitation: statistical analysis and modeling. Desalin Water Treat 51:1720–1726. https://doi.org/10.1080/19443994.2012.714652

Khankhaje E, Rafieizonooz M, Salim MR, Khan R, Mirza J, Siong HC, Salmiati (2018) Sustainable clean pervious concrete pavement production incorporating palm oil fuel ash as cement replacement. J Clean Prod 172:1476–1485. https://doi.org/10.1016/j.jclepro.2017.10.159

Kim S, Dale BE (2004) Global potential bioethanol production from wasted crops and crop residues. Biomass and Bioenergy 26:361–375. https://doi.org/10.1016/j.biombioe.2003.08.002

Kočí V, Maděra J, Jerman M, Žumár J, Koňáková D, Čáchová M, Vejmelková E, Reiterman P, Černý R (2016) Application of waste ceramic dust as a ready-to-use replacement of cement in lime-cement plasters: an environmental-friendly and energy-efficient solution. Clean Technol Environ Policy 18:1725–1733. https://doi.org/10.1007/s10098-016-1183-2

Kourti I, Deegan D, Boccaccini AR, Cheeseman CR (2013) Use of DC plasma treated air pollution control (APC) residue glass as pozzolanic additive in portland cement. Waste and Biomass Valorization 4:719–728. https://doi.org/10.1007/s12649-013-9210-6

Kunal, Rajor A, Siddique R (2016) Bacterial treatment of alkaline cement kiln dust using Bacillus halodurans strain KG1. Brazilian J Microbiol 47:1–9. https://doi.org/10.1016/j.bjm.2015.11.001

Lam CHK, Barford JP, McKay G (2011) Utilization of municipal solid waste incineration ash in Portland cement clinker. Clean Technol Environ Policy 13:607–615. https://doi.org/10.1007/s10098-011-0367-z

Legret M, Baron J, Astruc M (1990) Study of interactions between heavy metals and sewage sludges. Determination of stability constants and complexation capacities of complexes formed with Cu and Cd. Environ Technol (United Kingdom) 11:151–162. https://doi.org/10.1080/09593339009384850

Lertwattanaruk P, Makul N, Siripattarapravat C (2012) Utilization of ground waste seashells in cement mortars for masonry and plastering. J Environ Manage 111:133–141. https://doi.org/10.1016/j.jenvman.2012.06.032

Lim JS, Abdul Manan Z, Wan Alwi SR, Hashim H (2012) A review on utilisation of biomass from rice industry as a source of renewable energy. Renew Sustain Energy Rev 16:3084–3094. https://doi.org/10.1016/j.rser.2012.02.051

Maiorella BL (1985) Ethanol. In: Young M (ed) Comprehensive biotechnology. Pergamon Press, Oxford, pp 861–914

Mangi SA, Jamaluddin N, Wan Ibrahim MH, Abdullah AH, Abdul Awal ASM, Sohu S, Ali N (2017) Utilization of sugarcane bagasse ash in concrete as partial replacement of cement. Mater Sci Eng 271:012001. https://doi.org/10.1088/1757-899X/271/1/012001

Manoharan T, Laksmanan D, Mylsamy K, Sivakumar P, Sircar A (2018) Engineering properties of concrete with partial utilization of used foundry sand. Waste Manag 71:454–460. https://doi.org/10.1016/j.wasman.2017.10.022

Manso JM, Gonzalez JJ, Polanco JA (2004) Electric arc furnace slag in concrete. J Mater Civ Eng 16:639–645. https://doi.org/10.1061/(ASCE)0899-1561(2004)16:6(639)

Martínez-Lage I, Velay-Lizancos M, Vázquez-Burgo P, Rivas-Fernández M, Vázquez-Herrero C, Ramírez-Rodríguez A, Martín-Cano M (2016) Concretes and mortars with waste paper industry: biomass ash and dregs. J Environ Manage 181:1–11. https://doi.org/10.1016/j.jenvman.2016.06.052

Maslehuddin M, Awan FR, Shameem M, Ibrahim M, Ali MR (2011) Effect of electric arc furnace dust on the properties of OPC and blended cement concretes. Constr Build Mater 25:308–312. https://doi.org/10.1016/j.conbuildmat.2010.06.024

Method 1311 (1992) Toxicity characteristic leaching procedure. https://www.epa.gov/sites/production/files/2015-12/documents/1311.pdf

Munshi S, Dey G, Prasad Sharma R (2013) Use of rice straw ash as pozzolanic material in cement mortar. Int J Eng Technol.:603–606. https://doi.org/10.7763/ijet.2013.v5.626

Nayaka RR, Alengaram UJ, Jumaat MZ, Yusoff SB, Alnahhal MF (2018) High volume cement replacement by environmental friendly industrial by-product palm oil clinker powder in cement – lime masonry mortar. J Clean Prod 190:272–284. https://doi.org/10.1016/j.jclepro.2018.03.291

Pei R, Liu J, Wang S, Yang M (2013) Use of bacterial cell walls to improve the mechanical performance of concrete. Cem Concr Compos 39:122–130. https://doi.org/10.1016/j.cemconcomp.2013.03.024

Reijnders L (2005) Disposal, uses and treatments of combustion ashes: a review. Resour Conserv Recycl 43:313–336. https://doi.org/10.1016/j.resconrec.2004.06.007

Sable KS, Rathi MK (2012) Effect of different type of steel fibre and aspect ratio on mechanical properties of self compacted concrete. Int J Eng Innov Technol 2:184–188

Saxena V, Nielsen J (2004) Novel integrated bio-optical system for oxygen saturation measurement. In: Proc. SPIE 5368, Medical Imaging 2004: Physics of Medical Imaging

Sepehr MN, Zarrabi M, Amrane A (2012) Removal of CR(III) from model solutions by isolated Aspergillus niger and Aspergillus oryzae living microorganisms: equilibrium and kinetic studies. J Taiwan Inst Chem Eng 43:420–427. https://doi.org/10.1016/j.jtice.2011.12.001

Siddique R, Singh K, Kunal P et al (2016) Properties of bacterial rice husk ash concrete. Constr Build Mater 121:112–119. https://doi.org/10.1016/j.conbuildmat.2016.05.146

Statista (2018) Major countries in worldwide cement production from 2012 to 2017 (in a million metric tons). In: Stat. Portal. https://www.statista.com/statistics/267364/world-cement-production-by-country/. Accessed 1 Sep 2020

Tashima MM, Silva CAD, Akasaki JL, Barbosa MB (2004) The possibility of adding the rice husk ash (RHA) to the concrete. In: International RILEM Conference on the Use of Recycled Materials in Building and Structures. pp 778–786

Taştan BE, Ertuǧrul S, Dönmez G (2010) Effective bioremoval of reactive dye and heavy metals by Aspergillus versicolor. Bioresour Technol 101:870–876. https://doi.org/10.1016/j.biortech.2009.08.099

The Environmental Protection Rules (1986) General standards for discharge of environmental pollutants part-a : effluents. 545–560

Tiwari MK, Bajpai S, Dewangan UK, Tamrakar RK (2015) Suitability of leaching test methods for fly ash and slag: a review. J Radiat Res Appl Sci 8:523–537. https://doi.org/10.1016/j.jrras.2015.06.003

van Deventer JSJ, White CE, Myers RJ (2020) A roadmap for production of cement and concrete with low-CO2 emissions. Waste Biomass Valor 12:4745–4775. https://doi.org/10.1007/s12649-020-01180-5

Vieira CMF, Sanchez R, Monteiro SN, Lalla N, Quaranta N (2013) Recycling of electric arc furnace dust into red ceramic. J Mater Res Technol 2:88–92. https://doi.org/10.1016/j.jmrt.2012.09.001

Vijayakumar G, Vishaliny H, Govindarajulu D (2013) Studies on glass powder as partial replacement of cement in concrete production. Int J Emerg Technol Adv Eng 3:153–157

Acknowledgements

The authors also acknowledge the valuable comments raised by reviewers and support by Mr. Jay Kumar (M.Tech, Guru Nanak Dev Engineering College, Ludhiana) in improving the quality of the mansucript.

Funding

The authors are grateful to the Raytheon Chair for Systems Engineering, Advanced Manufacturing Institute, King Saud University, Saudi Arabia, for the funding.

Author information

Authors and Affiliations

Contributions

Conceptualisation: Amanpreet Kaur Sodhi and Neeraj Bhanot. Formal analysis: Amanpreet Kaur Sodhi, Neeraj Bhanot and Rajwinder Singh. Funding acquisition: Mohammed Alkahtani. Methodology: Neeraj Bhanot and Rajwinder Singh. Software: Rajwinder Singh. Supervision: Amanpreet Kaur Sodhi, Neeraj Bhanot and Mohammed Alkahtani. Validation: Amanpreet Kaur Sodhi and Mohammed Alkahtani. Writing—original draft: Neeraj Bhanot and Rajwinder Singh. Writing—review and editing: Amanpreet Kaur Sodhi, Neeraj Bhanot and Mohammed Alkahtani.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Statement of novelty

The current study reports on the combined utilisation of industrial (electric arc furnace dust) and agricultural waste (rice straw ash) along with microbes (Bacillus megaterium and Aspergillus niger) in concrete manufacturing in order to reduce the negative impacts of the wastes on the environment. This study has been conducted in three scenarios while observing the concrete properties vis-a-vis compressive strength and water absorption rate. Efforts have also been made to obtain optimal set of operating parameters being replacement percentage, curing days and cell concentration through integrated Taguchi-based design of experiments and genetic algorithm approach. The outcome of the study facilitated elimination of hazardous wastes to reduce their harmful impacts on environment along with improvement in concrete performance.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The current study reports on the combined utilisation of industrial (electric arc furnace dust) and agricultural waste (rice straw ash) along with microbes (Bacillus megaterium and Aspergillus niger) in concrete manufacturing in order to reduce the negative impacts of the wastes on the environment.

• This study has been conducted in three scenarios while observing the concrete properties vis-a-vis compressive strength and water absorption rate.

• Efforts have also been made to obtain optimal set of operating parameters being replacement percentage, curing days and cell concentration through integrated Taguchi-based design of experiments and genetic algorithm approach.

• The outcome of the study facilitated elimination of hazardous wastes to reduce their harmful impacts on environment along with improvement in concrete performance.

Supplementary information

ESM 1

(DOCX 26 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sodhi, A.K., Bhanot, N., Singh, R. et al. Effect of integrating industrial and agricultural wastes on concrete performance with and without microbial activity. Environ Sci Pollut Res 29, 86092–86108 (2022). https://doi.org/10.1007/s11356-021-16445-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-16445-2