Abstract

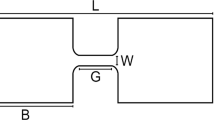

In this work an experimental technique to simultaneously measure the full-field temperature and deformation of composite material subjected to flame heating at high temperature is developed using the technique of image processing. The testing stage is integrated with an oxy-propane flame torch for flame heating, a CCD camera for image recording, a synchronized blue light source for light compensation and an infrared pyrometer for temperature calibration and comparison. The principle of the synchronous measurement of temperature and deformation field is demonstrated and discussed. Experiment on carbon fiber reinforced silicon carbide (C/SiC) composite was conducted to validate this method. The temperature was calculated using an improved two-color method while the displacement field and strain field were calculated using the digital image processing method. Results show that the proposed method is applicable for synchronous measurement of temperature and displacement by using one camera, and the mutual interference between the radiation and reflected light can also be effectively eliminated.

Similar content being viewed by others

References

Roewer G, Herzog U, Trommer K, Muller E, Fruhauf S (2002) Silicon carbide—a survey of synthetic approaches, properties and applications. In: Jansen M (ed) High performance non-oxide ceramics I, vol 101, Structure and bonding. Springer, Germany, pp 59–135

Krenkel W, Heidenreich B, Renz R (2002) C/C-SiC composites for advanced friction systems. Adv Eng Mater 4:427–436

Naslain R, Guette A, Rebillat F, Pailler R, Langlais F, Bourrat X (2004) Boron-bearing species in ceramic matrix composites for long-term aerospace applications. J Solid State Chem 177:449–456

Schmidt S, Beyer S, Knabe H, Immich H, Meistring R, Gessler A (2004) Advanced ceramic matrix composites materials for current and future propulsion technology applications. Acta Astronaut 55(3–9):409–420

Silvestroni L, Sciti D, Melandri C, Guicciardi S (2010) Toughened ZrB2-based ceramics through SiC whisker or SiC chopped fiber additions. J Eur Ceram Soc 30(11):2155–2164

Fang X, Liu F, Hengqiang S, Liu B, Xue F (2014) Ablation of C/SiC, C/SiC-ZrO2 and C/SiC-ZrB2 composites in dry air and air mixed with water vapor. Ceram Int 40(2):2985–2991

Suo T, Fan X, Hu G, Li Y, Tang Z, Xue P (2013) Compressive behavior of C/SiC composites over a wide range of strain rates and temperatures. Carbon 62:481–492

Yulong L, Tao S, Mingshuang L (2009) Influence of the strain rate on the mechanical behavior of the 3D needle-punched C/SiC composite. Mater Sci Eng A 507:6–12

LeBlanc J, Shukla A, Rousseau C et al (2007) Shock loading of three-dimensional woven composite materials. Compos Struct 79(3):344–355

LeBlanc J, Shukla A (2011) Dynamic response of curved composite panels to underwater explosive loading: experimental and computational comparisons. Compos Struct 93(11):3072–3081

Gauch E, LeBlanc J, Shukla A (2012) Response of preloaded thin composite panels subjected to underwater explosive loading. Comput Struct 112:342–353

Chu TC, Ranson WF, Sutton MA, Peters WH (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232–244

Bruck HA, Mcneill SR, Sutton MA, Peters WH (1989) Digital image correlation using Newton–Raphson method of partial differential correction. Exp Mech 29:261–267

Cofaru C, Philips W, van Paepegem W (2013) Pixel-level robust digital image correlation. Opt Express 21:29979–29999

Lyons JS, Liu J, Sutton MA (1996) High-temperature deformation measurements using digital-image correlation. Exp Mech 36(1):64–70

Swaminathan B, Lambros J, Sehitoglu H (2014) Digital image correlation study of mechanical response of nickel superalloy Hastelloy X under thermal and mechanical cycling: uniaxial and biaxial stress states. J Strain Anal Eng Des 49(4):233–243

Casperson MC, Carroll JD, Lambros J et al (2014) Investigation of thermal effects on fatigue crack closure using multiscale digital image correlation experiments. Int J Fatigue 61:10–20

Fang X, Yu H, Zhang G, Su H, Tang H, Feng X (2014) In-situ observation and measurement of composites subjected to extremely high temperature. Rev Sci Instrum 85(3):035104

Fang X, Jia J, Xue F (2015) Three-point bending test at extremely high temperature enhanced by real-time observation and measurement. Measurement 59:171–176

Grant BMB, Stone HJ, Withers PJ, Preuss M (2009) High-temperature strain field measurement using digital image correlation. J Strain Anal Eng Des 44:263–271

Su H, Fang X, Feng X, Ya B (2014) Temperature-dependent modulus of metals based on lattice vibration theory. J Appl Mech 81:041017

Su H, Fang X, Feng X, Yan B (2014) The temperature-dependent strength of metals: theory and experimental validation. J Appl Mech 81:091003

Hottel HC, Broughton FP (1932) Determination of true temperature and total radiation from luminous flame. Ind Eng Chem Anal Ed 4:166–175

Huang Y, Yan Y, Riley G (2000) Vision-based measurement of temperature distribution in a 500-kW model furnace using the two-colour method. Measurement 28:175–183

Hijazi A, Sachidanandan S, Singh R, Madhavan V (2011) A calibrated dual-wavelength infrared thermometry approach with non-graybody compensation for machining temperature measurements. Meas Sci Technol 22:025106. doi:10.1088/0957-0233/22/2/025106

Pan B, **e HM, Hua T, Asundi A (2009) Measurement of coefficient of thermal expansion of films using digital image correlation method. Polym Test 28:75–83

Schreier H, Orteu J-J, Sutton MA (2009) Image correlation for shape, motion and deformation measurements. Springer Science + Business Media, USA

Acknowledgments

We gratefully acknowledge the support of National Natural Science Foundation of China (Grant Nos. 11222220, 11320101001, 11227801), the National Basic Research Program of China (Grant No. 2015CB351900) and Tsinghua University Initiative Scientific Research Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Honghong Su and Xufei Fang contributed equally to this work.

Rights and permissions

About this article

Cite this article

Su, H., Fang, X., Qu, Z. et al. Synchronous Full-Field Measurement of Temperature and Deformation of C/SiC Composite Subjected to Flame Heating at High Temperature. Exp Mech 56, 659–671 (2016). https://doi.org/10.1007/s11340-015-0066-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0066-5