Abstract

When a textured ring rotates relatively against the other texture-free ring in a parallel thrust bearing, cavitation of liquid lubricant may occur in the divergent zones of the dimples or grooves on the textured surface due to local pressure drops. The Reynolds and Jakobsson–Floberg–Olsson (JFO) models are two widely used cavitation models in hydrodynamic lubrication theory, where the former lacks mass conservation while the latter enforces it. In order to investigate the applicability of the two models to the hydrodynamic lubrication analysis of parallel thrust bearings with surface textures, comparison between experiment and simulation results has been carried out on parallel thrust bearings in terms of cavitation zone morphology in a groove, friction coefficient, and bearing clearance. The results have shown that the observed cavitation morphology in steady state is more similar to the prediction from the JFO model than that from the Reynolds model.

Similar content being viewed by others

Abbreviations

- F :

-

Cavitation index

- F f :

-

Friction force (N)

- f c :

-

Friction coefficient

- h :

-

Local film thickness (m)

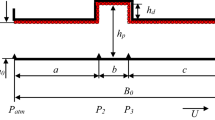

- h d :

-

Groove depth (m)

- \( \bar{h} \) :

-

Dimensionless local film thickness = h/h d

- h 0 :

-

Bearing clearance (m)

- h 01, h 02 :

-

Guess of bearing clearance (m)

- h 0g :

-

Average of h 01 and h 02 (m)

- N :

-

Number of grooves

- P :

-

Local pressure (Pa)

- P c :

-

Cavitation pressure (Pa)

- P ref :

-

Characteristic reference pressure (Pa)

- \( \bar{P} \) :

-

Dimensionless local pressure = P/P 0

- P 0 :

-

Ambient pressure (Pa)

- p :

-

Nominal mean contact pressure = W/(r 2o − r 2i )/π (Pa)

- r :

-

Radial coordinate in a polar coordinate system (m)

- r i, r o :

-

The inner and outer radii of the textured ring (m)

- \( \bar{r} \) :

-

Dimensionless radial coordinate = r/r i

- W :

-

Measured normal load (N)

- W g :

-

Calculated normal load (N)

- x, y :

-

Coordinates in a Cartesian coordinate system (m)

- \( \bar{x},\bar{y} \) :

-

Dimensionless coordinates, \( \bar{x} = x/r_{i} ,\bar{y} = y/r_{\text{i}} \)

- α :

-

Groove area ratio = ∆θ g/θ c

- ϕ :

-

Dimensionless dependent variable

- η :

-

Dynamic viscosity of lubricant (Pa s)

- λ Rey, λ JFO :

-

Dimensionless parameters: \( \lambda_{\text{Rey}} = 6\eta \omega r_{i}^{2} /P_{0} /h_{d}^{2} ,\lambda_{\text{JFO}} = 6\eta \omega r_{i}^{2} /\left( {P_{\text{ref}} - P_{\text{c}} } \right)/h_{\text{d}}^{2} \)

- θ :

-

Angular coordinate in a polar coordinate system (rad)

- θ c :

-

Angle of a periodic sector (rad)

- ∆θ g :

-

Angle of the groove in a periodic sector (rad)

- ρ :

-

Density (kg/m3): in the liquid film region, ρ = ρ c; in the cavitation region, ρ is the average density of the two-phase fluid of liquid and gas

- ρ c :

-

Lubricant density at the cavitation pressure (kg/m3)

- τ :

-

Viscous shear stress (Pa)

- ω :

-

Angular velocity (rad/s)

- i :

-

Index for the node number in the radial direction

- j :

-

Index for the node number in the angular direction

- k :

-

Iterative index

References

Wang, X.L., Adachi, K., Otsuka, K., Kato, K.: Optimization of the surface texture for silicon carbide sliding in water. Appl. Surf. Sci. 253, 1282–1286 (2006)

Wakuda, M., Yamauchi, Y., Kanzaki, S.: Effect of workpiece properties on machinability in abrasive jet machining of ceramic materials. Precis. Eng. 26, 193–198 (2002)

Etsion, I.: Improving tribological performance of mechanical components by laser surface texturing. Tribol. Lett. 17, 733–737 (2004)

Etsion, I., Halperin, G.: A laser surface textured hydrostatic mechanical seal. Tribol. Trans. 45, 430–434 (2002)

Brizmer, V., Kligerman, Y., Etsion, I.: A laser surface textured parallel thrust bearing. Tribol. Trans. 46, 397–403 (2003)

Ryk, G., Kligerman, Y., Etsion, I.: Experimental investigation of laser surface texturing for reciprocating automotive components. Tribol. Trans. 45, 444–449 (2002)

Zhou, L., Kato, K., Vurens, G., Talke, F.E.: The effect of slider surface texture on flyability and lubricant migration under near contact conditions. Tribol. Int. 36, 269–277 (2003)

Suh, N.P., Mosleh, M., Howard, P.S.: Control of friction. Wear 175, 151–158 (1994)

Tian, H., Saka, N., Suh, N.P.: Boundary lubrication studies on undulated titanium surfaces. Tribol. Trans. 32, 289–296 (1989)

Wakuda, M., Yamauchi, Y., Kanzaki, S., Yasuda, Y.: Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254, 356–363 (2003)

Wang, Q.J., Zhu, D.: Virtual texturing: modeling the performance of lubricated contacts of engineered surfaces. J. Tribol. Trans. ASME 127, 722–728 (2005)

Dowson, D., Taylor, C.M.: Cavitation in bearings. Ann. Rev. Fluid Mech. 11, 35–66 (1979)

Brewe, D.E., Ball, J.H., Khonsari, M.M.: Current research in cavitating fluid films. NASA Technical Memorandum, AVSCOM 89-C-007 (1988)

Heshmat, H.: The mechanism of cavitation in hydrodynamic lubrication. Tribol. Trans. 34, 177–186 (1991)

Jakobsson, B.O., Floberg, L.: The finite journal bearing considering vaporization. Report No. 190, Chalmers University of Technology, Goteborg, Sweden (1957)

Olsson, K.O.: Cavitation in dynamically loaded journal bearings. Report No. 308, Chalmers University of Technology, Goteborg, Sweden (1965)

Etsion, I., Halperin, G., Brizmer, V., Kligerman, Y.: Experimental investigation of laser surface textured parallel thrust bearings. Tribol. Lett. 17, 295–300 (2004)

Yu, H.W., Wang, X.L., Zhou, F.: Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces. Tribol. Lett. 37, 123–130 (2010)

Ausas, R., Ragot, P., Leiva, J., Jai, M., Bayada, G., Buscaglia, G.C.: The impact of the cavitation model in the analysis of microtextured lubricated journal bearings. J. Tribol. Trans. ASME 129, 868–875 (2007)

Qiu, Y., Khonsari, M.M.: On the prediction of cavitation in dimples using a mass-conservative algorithm. J. Tribol. Trans. ASME 131, (2009)

Costa, H.L., Hutchings, I.M.: Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 40, 1227–1238 (2007)

Zhang, J.Y., Meng, Y.G.: A study of surface texturing of carbon steel by photochemical machining. J. Mater. Process. Technol. (under review)

Harp, S.R., Salant, R.F.: An average flow model of rough surface lubrication with inter-asperity cavitation. J. Tribol. Trans. ASME 123, 134–143 (2001)

Braun, M.J., Hannon, W.M.: Cavitation formation and modelling for fluid film bearings: a review. Proc. Inst. Mech. Eng. J 224, 839–863 (2010)

Szeri, A.Z.: Tribology: friction, lubrication, and wear. Hemisphere Publishing Corp., New York (1980)

Elrod, H.G.: A cavitation algorithm. J. Lubr. Technol. Trans. ASME 103, 350–354 (1981)

Payvar, P., Salant, R.F.: A computational method for cavitation in a wavy mechanical seal. J. Tribol. Trans. ASME 114, 199–204 (1992)

Wen, S.Z., Huang, P.: Principles of tribology. Tsinghua University Press, Bei**g (2002)

Yu, T.H., Sadeghi, F.: Groove effects on thrust washer lubrication. J. Tribol. Trans. ASME 123, 295–304 (2001)

Etsion, I., Ludwig, L.P.: Observation of pressure variation in the cavitation region of submerged journal bearings. J. Lubr. Technol. Trans. ASME 104, 157–163 (1982)

Groper, M., Etsion, I.: The effect of shear flow and dissolved gas diffusion on the cavitation in a submerged journal bearing. J. Tribol. Trans. ASME 123, 494–500 (2001)

Groper, M., Etsion, I.: Reverse flow as a possible mechanism for cavitation pressure build-up in a submerged journal bearing. J. Tribol. Trans. ASME 124, 320–326 (2002)

Acknowledgments

This study was supported by the Natural Science Foundation of China (NSFC, Grant Nos. 50823003 and 51021064) and the National Basic Resaerch Program of China with the grant No. 2012CB934101.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Meng, Y. Direct Observation of Cavitation Phenomenon and Hydrodynamic Lubrication Analysis of Textured Surfaces. Tribol Lett 46, 147–158 (2012). https://doi.org/10.1007/s11249-012-9935-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-9935-6