Abstract

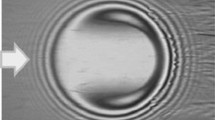

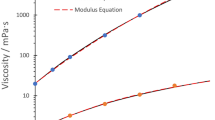

The free-volume viscosity model can accurately predict the temperature–pressure–viscosity relationship of lubricants. However, it is seldom used in elastohydrodynamic lubrication (EHL) simulation. This paper presents the application of the free-volume viscosity model in a Newtonian EHL simulation of a squalane-lubricated circular contact. Good agreement is observed between available experimental data and simulation results. The pressure–viscosity coefficients fit from viscometer data are also discussed. A recently developed definition of the coefficient is used to compare the coefficient value extracted from EHL film thickness interference measurements. Results indicate that the coefficient values from the curve fitting and EHL film thickness extraction agree well which has not been previously observed. Two factors help achieve this agreement: the new coefficient definition and smaller prediction error when using the Hamrock–Dowson formula in the cases studied. The effects of different pressure–viscosity relationships, including the exponential model, the Roelands model and the free-volume model, are investigated through an example with bright stock mineral oil. It is found that the real pressure–viscosity behavior predicted by the free-volume model yields a higher viscosity at the low-pressure area which results in a larger central film thickness. Therefore, due to use of the free-volume model, the present results are more consistent with experimental observations than previously reported numerical results.

Similar content being viewed by others

Abbreviations

- a :

-

Hertzian contact radii, (m)

- A 1, A 2 :

-

Yasutomi parameters

- b :

-

Intercept of the straight line in the coordinate of Log(h cen) vs. Log(u) in equation (14)

- B :

-

Doolittle parameter

- B 1, B 2 :

-

Yasutomi parameters

- c :

-

Constant in equations (15) and (16)

- C E :

-

Coefficients for elastic deformation in the film thickness equation, \(C_{\rm E}=\frac{2p_{\rm h}}/({\pi{E}^{\prime}})\)

- C G :

-

Coefficients for geometry term in the film thickness equation, \(C_{\rm G}=\frac{a}/({2R})\)

- c a , c b :

-

Coefficients for pressure–density equation, c a = 0.6 × 10−9, c b = 1.7 × 10−9

- C a , C b :

-

Dimensionless coefficients for pressure–density equation, C a = c a p h, C b = c b p h

- C 1, C 2 :

-

Yasutomi parameters

- E 1, E 2 :

-

Young’s modulus of two surfaces, (Pa)

- E′:

-

Reduced Young’s modulus of two surfaces, \(1/E^{\prime}=((1-\mu_1^2)/E_1+(1-\mu_2^2)/E_2)/2\), (Pa)

- F :

-

Relative free-volume expansivity

- G * :

-

Dimensionless material parameter, G * = α E′

- h, H :

-

Film thickness, (m), and its dimensionless value, H = h/a

- h 0, H 0 :

-

Normal approach of two surfaces, (m), and its dimensionless value, H 0 = h 0/a

- h cen, h min :

-

Central film thickness and minimum film thickness, (nm)

- K 0 :

-

Bulk modulus at p = 0, (GPa)

- K ′0 :

-

Pressure rate of change of bulk modulus at p = 0

- p :

-

Pressure, (Pa)

- p iv(∞):

-

Asymptotic isoviscous pressure, (Pa)

- p iv(p):

-

Isoviscous pressure, (Pa)

- p h :

-

Maximum Hertzian pressure, (Pa)

- P :

-

Dimensionless pressure, P = p/p h

- R :

-

Ball radii

- T :

-

Temperature, (°C)

- T g :

-

Glass transition temperature, (°C)

- \(T_{\rm g_{0}}\) :

-

Glass transition temperature for p = 0, (°C)

- u 1, u 2 :

-

Velocities of two surfaces, (m/s)

- u :

-

Entrainment velocity, u = (u 1 + u 2)/2, (m/s)

- U * :

-

Dimensionless speed parameter, U * = uη0/(E′R)

- v :

-

Volume, (m3)

- v 0 :

-

Volume at ambient pressure or p = 0, (m3)

- v occ :

-

Occupied volume, (m3)

- V(X, Y):

-

Dimensionless elastic deformation, see equations (2) and (3)

- w :

-

Load, (N)

- W * :

-

Dimensionless load parameter, W * = w/(E′R 2)

- x, y :

-

Coordinates, (m)

- X, Y :

-

Dimensionless coordinates X = x/a,Y = y/a

- Z :

-

Roelands pressure–viscosity exponential

- α:

-

Pressure–viscosity coefficient, (1/Pa)

- α0 :

-

Conventional pressure–viscosity coefficient, (1/Pa)

- α* :

-

Reciprocal asymptotic isoviscous pressure coefficient, (1/Pa)

- αB :

-

Secant pressure–viscosity coefficient, (1/Pa)

- αfilm :

-

New definition of pressure–viscosity coefficient, (1/Pa)

- αexp :

-

Pressure–viscosity coefficient extracted from film thickness measurement, (1/Pa)

- αf :

-

Thermal expansion coefficient, (1/°C)

- ΔX, ΔY :

-

Dimensionless mesh spacing in x- and y- directions

- \(\varepsilon\) :

-

Dimensionless coefficients for Poiseuille flow

- η:

-

Viscosity, (Pa·s)

- η0 :

-

Viscosity at ambient pressure, (Pa·s)

- ηg :

-

Glass transition viscosity, (Pa·s)

- \(\bar{\eta}\) :

-

Dimensionless viscosity, \(\bar{\eta}=\eta/\eta_{0}\)

- μ1, μ2 :

-

Poisson ratios of two surfaces

- ρ:

-

Density of lubricant, (kg/m3)

- ρ0 :

-

Density at ambient pressure, (kg/m3)

- \(\bar{\rho}\) :

-

Dimensionless density, \(\bar{\rho}=\rho/\rho_{0}\)

- Ω:

-

Solution domain

References

Barus C. (1983) Am. J. Sci. 45:87

C.J.A. Roelands, Correlational Aspects of the Viscosity–Temperature–Pressure Relationship of Lubricating Oils, PhD thesis (Delft University, Delft, 1996)

Bair S. (2002) Proc. Instn. Mech. Engrs. 216(J) :223

Bair S. (2004) Proc. Instn. Mech. Engrs. 218(J1) :57

Doolittle A.D. (1951) J. Appl. Phys. 22(12) :1471

Williams M.L., Landel R.F., Ferry J.D. (1955) J. Am. Chem. Soc. 77:3701

Yasutomi S., Bair S., Winer W.O. (1984) ASME J. Lubr. Techn. 106(2):291

Cook R.L., Herbst C.A., King H.E. Jr. (1993) J. Phys. Chem. 97:2355

Bair S. (2001) ASME J. Tribol. 123(1) :50

Ehret P., Dowson D., Taylor C.M. (1998) Proc. Roy. Soc. London A 454:763

Kaneta M., Nishikawa H., Kameishi K. et al. (1992) ASME J. Tribol. 114:75

Jacob B., Venner C.H., Lugt P.M. (2003) ASME J. Tribol. 125(4):739

S. Bair, Y.C. Liu and Q.J. Wang, ASME J. Tribol. 128(3) (2006) 624

Yang P., Kaneta M., Masuda S. (2005) ASME J. Tribol. 127(2):457

Bair S. (2005) ASME J. Tribol. 127(2) :458

Hartl M., Molimard J., Krupka I. et al. (2001) STLE Tribol. Trans. 44(2):270

M. Kaneta, N. Tani and H. Nishikawa, in: Tribological Research and Design for Engineering System, eds. D. Dowson et al. (Elsevier, 2003) 101

Hu Y.Z., Zhu D. (2000) ASME J. Tribol. 122(1) :1

Liu S.J., Wang Q.J., Liu G. (2000) Wear 243(1–2) :101

Wang W.Z., Liu Y.C., Hu Y.Z., Wang H. (2004) ASME J. Tribol. 126(1):162

Y.C. Liu, Q.J. Wang, W.Z. Wang, Y.Z. Hu and D. Zhu, ASME J. Tribol. 128(3) (2006) 641

Dowson D., Higginson G.R. (1966) Elastohydrodynamic Lubrication. Pergamon Press, Oxford

Foord C.A., Hammann W.C., Cameron A. (1968) ASLE Trans. 11:31

Johnson G.J., Wayte R., Spikes H.A. (1991) STLE Tribol. Trans. 34:187

Glovnea R.P., Olver A.V., Spikes H.A. (2005) STLE Tribol. Trans. 48:328

Hamrock B.J., Dowson D. (1977) ASME J. Lubr. Tech. 99(2) :264

Krupka I., Hartl M., Liska M. (2005) ASME J. Tribol. 127(4) :890

Cooper D., Moore A.J. (1994) Wear 175:93

Bair S. (2000) Proc. Instn. Mech. Engrs. 214(J) :515

Jones W.R. (1995) STLE Tribol. Trans. 38:560

Zhao J., Sadeghi F. (2003) ASME J. Tribol. 125(1) :76

S. Bair, in: IUTAM Symposium on Elastohydrodynamics and Micro-Elastohydrodynamics, eds. R.W. Snidle and H.P. Evans (Springer-Verlag, 2006)

Glovnea R.P., Spikes H.A. (2001) ASME J. Tribol. 123:254

H. Blok, in: Proceedings of the International Symposium on Lubrication and Wear, eds. D. Muster and B. Sternlicht (McCutchan, 1963) 74

Venner C.H., Lubrecht A.A. (1994) ASME J. Tribol. 116(4) :751

Kaneta M., Sakai T., Nishikawa H. (1992) ASME J. Tribol. 114:779

Felix-Quinonez A., Ehret P., Summers J.L. (2004) Proc. Instn. Mech. Engrs. 218(J) :109

Krupka I., Hartl M., Poliscuk R. et al. (2000) ASME J. Tribol. 122(4) :689

Acknowledgments

Yuchuan Liu and Q. Jane Wang would like to express their gratitude for the support from Office of Naval Research, Department of Energy, Eaton Corporation and Center for Surface Engineering & Tribology (CSET) at Georgia Institute of Technology & Northwestern University. The experimental results were obtained with the support of the Ministry of Education, Youth and Sports of the Czech Republic (Project MSM0021630508). Dr. Scott Bair of Georgia Institute of Technology should be acknowledged for providing the viscosity measurements. Ms. Ashlie Martini should also be acknowledged for her help in manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., J. Wang, Q., Wang, W. et al. EHL simulation using the free-volume viscosity model. Tribol Lett 23, 27–37 (2006). https://doi.org/10.1007/s11249-006-9101-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-006-9101-0