Abstract

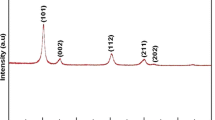

In the growing field of nanomaterials, SiC nanoparticles arouse interest for numerous applications. The inductively coupled plasma (ICP) technique allows obtaining large amount of SiC nanopowders from cheap coarse SiC powders. In this paper, the effects on the SiC structure of the process pressure, the plasma gas composition, and the precursor nature are addressed. The powders were characterized by X-ray diffraction (XRD), Raman and fourier transform infrared (FT-IR) spectroscopy, scanning electron microscopy (SEM) and high resolution electron microscopy (HREM), chemical analyses, BET and photon correlation spectroscopy (PCS) measurements. Whatever the precursor (α- or β-SiC), the nanoparticles were crystallised in the cubic β-SiC phase, with average sizes in the 20–40 nm range. Few residual grains of precursor were observed, and the decarburization due to the reductive Ar–H2 plasma lead to the appearance of Si nanograins. The stoichiometry of the final product was found to be controllable by the process pressure and the addition of methane.

Similar content being viewed by others

References

Vassen R, Stöver D (1997) Phil Mag B 76:585

Vassen R, Kaiser A, Stöver D (1996) J Nucl Mater 233–237:708

Donato A, Borsella E, Botti S, Martelli S, Nannetti CA, Mancini MR, Morjan IJ (1996) Nucl Mater 233–237:814

Chae KW, Niihara K, Kim DY (1995) J Mat Sci Lett 14:1332

Endo H, Ueki M, Kubo HJ (1991) Mat Sci 26:3769

Vassen R, Stöver D (2001) Mat Sci Eng A 301:59

Fu Z, Ning J, Yang B, Wu W, Pan H, Xu P (2003) Mater Lett 57:1910

Ledoux MJ, Pham-Huu C (2001) CaTTech 5:226

Guichelaar PJ (1997) In: Carbide, nitride and boride materials synthesis and processing. Chapman and Hall

Setiowati U, Kimura SJ (1997) Am Ceram Soc 80:757

Hatakeyama F, Kanzaki SJ (1990) Am Ceram Soc 73:2107

Seong IS, Kim CH (1993) J Mater Sci 28:3277

Klein S, Winterer M, Hahn H (1998) Chem Vapor Depos 4:143

Chen LD, Goto T, Hirai TJ (1989) Mater Sci 24:3824

Yamada O, Miyamoto Y, Koizumi MJ (1986) Mater Res 1:275

Satapathy LN, Ramesh PD, Agrawal D, Roy R (2005) Mater Res Bull 40:1871

Suyama Y, Marra RM, Haggerty JS, Bowen HK (1985) Am Ceram Soc Bull 64:1356

Cauchetier M, Croix O, Luce M (1998) Adv Ceram Mat 3:548

Ando Y, Ohkohchi M, Uyeda R (1980) Jpn J Appl Phys 19:693

Inoue Y, Nariki Y, Tanaka KJ (1989) Mater Sci 24:3819

Hollabaugh CM, Hull DE, Newkirk LR, Petrovic JJ (1983) J Mater Sci 18:3190

Kameyama T, Sakanaka K, Motoe A, Tsunoda T, Nakanaga T, Wakayama NI, Takeo H, Fukuda K (1990) J Mater Sci 25:1058

Guo JY, Gitzhofer F, Boulos MI (1995) J Mater Sci 30:5589

Kong P, Pfender E (1987) Langmuir 3:259

Lee HJ, Eguchi K, Yoshida T (1990) J Am Ceram Soc 73:3356

Leparoux M, Schreuders C, Shin JW, Siegmann S (2005) Adv Eng Mater 7:349

Shin JW, Miyazoe H, Leparoux M, Siegmann S, Dorier JL, Hollenstein C (2006) Plasma Sources Sci Technol 15:441

Nakashima S, Harima H (1997) Phys Stat Sol A 162:39

Burton JC, Sun L, Long FH, Feng ZC, Ferguson T (1999) Phys Rev B 59:7282

Papoular R, Cauchetier M, Begin S, Le Caer G (1998) Astron Astrophys 329:1035

Boulos MH, Fauchais P, Pfender E (1994) In: Thermal plasmas—fundamentals and applications. Plenum Press editors

Colder H, Rizk R, Morales M, Marie P, Vicens J, Vickridge I (2005) J Appl Phys 98:024313

Acknowledgements

The authors thank C. Schreuders, G. Bürki, and M. Aeberhard (EMPA Thun) for modelling, SEM observations, and XRD characterizations respectively, W. Graehlert (FhG-IWS, Dresden) for Raman spectroscopy, J. Glory and A. Habert (LFP Saclay) for PCS and BET measurements respectively, O. Syrdal (Saint-Gobain) for the SiC microscale powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leconte, Y., Leparoux, M., Portier, X. et al. Controlled Synthesis of β-SiC Nanopowders with Variable Stoichiometry Using Inductively Coupled Plasma. Plasma Chem Plasma Process 28, 233–248 (2008). https://doi.org/10.1007/s11090-007-9072-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-007-9072-4