Abstract

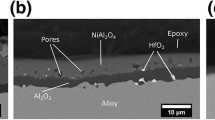

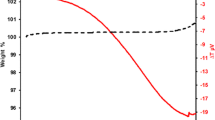

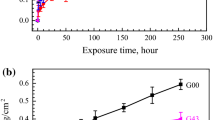

γ-NiCrAl alloys with relatively low Al contents tend to form a layered oxide scale during the early stages of oxidation, rather than an exclusive α-Al2O3 scale, the so-called “thermally grown oxide” (TGO). A layered oxide scale was established on a model γ-Ni–28Cr–11Al (at.%) alloy after isothermal oxidation for several minutes at 1100°C. The layered scale consisted of an NiO layer at the oxide/gas interface, an inner Cr2O3 layer, and an α-Al2O3 layer at the oxide/alloy interface. The evolution of such an NiO/Cr2O3/Al2O3 layered structure on this alloy differs from that proposed in earlier work. During heating, a Cr2O3 outer layer and a discontinuous inner layer of Al2O3 initially formed, with metallic Ni particles dispersed between the two layers. A rapid transformation occurred in the scale shortly after the sample reached maximum temperature (1100°C), when two (possibly coupled) phenomena occurred: (i) the inner transition alumina transformed to α-Al2O3, and (ii) Ni particles oxidized to form the outer NiO layer. Subsequently, NiO reacted with Cr2O3 and Al2O3 to form spinel. Continued growth of the oxide scale and development of the TGO was dominated by growth of the inner α-Al2O3 layer.

Similar content being viewed by others

References

G. R. Wallwork and A. Z. Hed, Oxidation of Metals 3, 171 (1971).

C. S. Gigins and F. S. Pettit, Journal of Electrochemical Society 118, 1782 (1971).

T. J. Nijdam, L. P. H. Jeurgens, and W. G. Sloof, Materials at High Temperatures 20, 311 (2003).

A. G. Evans, D. R. Mumm, J. W. Hutchinson, G. H. Meier, and F. S. Pettit, Progress in Materials Science 46, 505 (2001).

T. J. Nijdam, L. P. H. Jeurgens, and W. G. Sloof, Acta Materialia 53, 1643 (2005).

T. J. Nijdam, N. M. van der Pers, and W. G. Sloof, Materials and Corrosion 57, 269 (2006).

B. W. Veal, A. P. Paulikas, and P. Y. Hou, Nature Materials 5, 349 (2006).

A. Reddy, D. B. Hovis, A. H. Heuer, A. P. Paulikas, and B. W. Veal, Oxidation of Metals 67, 153 (2007).

D. Hovis and A. H. Heuer, Scripta Materialia 53, 347 (2005).

L. J. Grabner, Journal of Applied Physics 49, 580 (1978).

D. M. Lipkin and D. R. Clarke, Oxidation of Metals 45, 267 (1996).

A. Gil, V. Shemet, R. Vassen, M. Subanovic, J. Toscano, D. Naumenko, L. Singheiser, and W. J. Quadakkers, Surface and Coatings Technology 201, 3824 (2006).

F. A. Golightly, G. C. Wood, and F. H. Scott, Oxidation of Metals 14, 217 (1980).

K. Wefers and C. Misra, Oxides and Hydroxides of Aluminum, Alcoa Technical Paper No. 19, Alcoa Laboratories, Pittsburgh, PA (1987).

J. L. Smialek and R. Gibala, Metallurgical Transactions A 14A, 2143 (1983).

J. Doychak, J. L. Smialek, and T. E. Mitchell, Metallurgical Transactions A 20A, 499 (1989).

A. Vlad, A. Stierle, N. Kasper, H. Dosch, and M. Rühle, Journal of Materials Research 21, 3047 (2006).

L. Hu, D. Hovis, and A. H. Heuer, Scripta Materialia 61, 157 (2009).

M. W. Brumm and H. J. Grabke, Corrosion Science 33, 1677 (1992).

H. J. Grabke, Intermetallics 7, 1153 (1999).

G. C. Rybicki and J. L. Smialek, Oxidation of Metals 31, 275 (1989).

B. A. Pint, J. R. Martin, and L. W. Hobbs, Solid State Ionics 78, 99 (1995).

R. Prescott, D. F. Mitchell, M. J. Graham, and J. Doychak, Corrosion Science 37, 1341 (1995).

P. Y. Hou, A. P. Paulikas, and B. W. Veal, Materials at High Temperatures 22, 535 (2005).

Acknowledgments

Professor Carlos G. Levi (University of California, Santa Barbara) is acknowledged for providing the NiCrAl alloys. The Office of Naval Research supported this research, under Contract No. N-00014-06-1-0760, Dr. D. Schiffler, Program Monitor. We are grateful to Dr. Boyd Veal and Mr. A. Palukas for access to their in situ APS oxidation facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, L., Hovis, D.B. & Heuer, A.H. Transient Oxidation of a γ-Ni–28Cr–11Al Alloy. Oxid Met 73, 275–288 (2010). https://doi.org/10.1007/s11085-009-9179-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-009-9179-5