Abstract

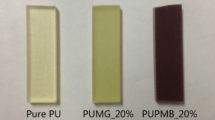

The energy dissipation characteristics of polyurea and polyurea/carbon black composites are determined under cycling loading at different amplitudes and excitation frequencies. These characteristics are measured experimentally and validated against the predictions of finite element models (FEM). Further validation of the energy dissipated is carried out by comparisons with the product of the storage modulus and the loss factor of the polymer as obtained from the measurement of the complex moduli using the Dynamic Mechanical Thermal Analyzer (DMTA). The obtained results indicate an excellent agreement between the experiments and the predictions of the FEM. Furthermore, it is observed that the energy dissipated per unit volume of pristine polyurea is, on average, about 10% higher than that of polyurea/carbon black composites.

Similar content being viewed by others

References

Amini, M.R., Simon, J., Nemat-Nasser, S.: Numerical modeling of effect of polyurea on response of steel plates to impulsive loads in direct pressure-pulse experiments. Mech. Mater. 42, 615–627 (2010a)

Amini, M.R., Simon, J., Nemat-Nasser, S.: Investigation of effect of polyurea on response of steel plates to impulsive loads in direct pressure-pulse experiments. Mech. Mater. 42, 628–639 (2010b)

Amirkhizi, A.V., Isaacs, J., Mcgee, J., Nemat-Nasser, S.: An experimentally-based viscoelastic constitutive model for polyurea, including pressure and temperature effects. Philos. Mag. 86(36), 5847–5866 (2006)

ASTM Standards D638: Standard test method for tensile properties of plastics. ASTM International, West Conshohocken, PA (2014)

Bahei-El-Din, Y.A., Dvorak, G.J., Fredricksen, O.J.: A impact tolerant sandwich plate design with a polyurea interlayer. Int. J. Solids Struct. 43, 7644–7658 (2006)

Bodin, C.: Energy storage and dissipation in polyurea composites. Master of Science in Mechanical Engineering Thesis, Massachusetts Institute of Technology (2013)

Carbone, G., Persson, B.N.J.: Crack motion in viscoelastic solids: the role of the flash temperature. Eur. Phys. J. E 17, 261–281 (2005)

Darab, B.: Dissipation of vibration energy using viscoelastic granular materials. Ph.D. Thesis, University of Sheffield (2013)

El-Sabbagh, A., Baz, A.: Topology optimization of unconstrained dam** treatments for plates. Eng. Optim. 46(9), 1153–1168 (2014)

Fuith, A., Reinecker, M., Sánchez-Ferrer, A., Mezzenga, R., Mrzel, A., Knite, M., Aulika, I., Dunce, M., Schranz, W.: Dynamic- and thermo-mechanical analysis of inorganic nanotubes/elastomer composites. Sens. Transducers J. 12, 71–79 (2011)

Gardner, N., Wang, E., Kumar, P., Shukla, A.: Blast mitigation in a sandwich composite using graded core and polyurea interlayer. Exp. Mech. 2012(52), 119–133 (2012)

Han, S., Chung, D.D.L.: Mechanical energy dissipation using carbon fiber polymer–matrix structural composites with filler incorporation. J. Mater. Sci. 47, 2434–2453 (2012)

Huang, W., Yang, Y., Li, H., Lyu, P., Zhang, R.: Characterization and Dam** Property of a Modified Polyurea Material. International Conference on Transportation Infrastructure and Materials (ICTIM 2017) (2017). ISBN 978-1-60595-442-4

Iqbal, N., Tripathi, M., Parthasarathy, S., Kumar, D., Roy, P.K.: Polyurea coatings for enhanced blast-mitigation: a review. RSC Adv. 6, 109706–109717 (2016)

Kanchwala, M.Z.: Testing and design life modeling of polyurea liners for potable water pipes. Master of Science Thesis, Department of Civil Engineering, the University of Texas at Arlington (2010)

Kolenda, J.: Dissipation energy in viscoelastic solids under multiaxial loads. Pol. Marit. Res. 1(15), 19–28 (2008)

Lakes, R.S.: Viscoelastic Materials. Cambridge University Press, Cambridge (2009)

Li, Y., Xu, M.: Hysteresis loop and energy dissipation of viscoelastic solid models. Mech. Time-Depend. Mater. 11(1), 1–14 (2007)

Mott, P.H., Giller, C.B., Fragiadakis, D., Rosenberg, D.A., Roland, C.M.: Deformation of polyurea: where does the energy go? Polymer 105, 227–233 (2016)

Oh, J., Ray, M.C., Baz, A.M.: Engineered dam** treatments. In: Inman, D. (ed.) Smart Structures and Materials 2001: Dam** and Isolation, 4–8 March 2001, Newport Beach, CA. Proceedings of the SPIE, vol. 4331, pp. 43–59 (2001). https://doi.org/10.1117/12.432730

Ramirez, B.J.: Manufacturing and characterization of temperature-stable, novel, viscoelastic polyurea based foams for impact management. Ph.D. Thesis in Mechanical Engineering, University of California Los Angeles (2017)

Shim, J.: Finite strain behavior of polyurea for a wide range of strain rates. Ph.D. Thesis, MIT, Cambridge, Massachusetts (2010)

Shim, J., Moh, D.: Punch indentation of polyurea at different loading velocities: experiments and numerical simulations. Mech. Mater. 43(7), 349–360 (2011)

Symans, M.D., Charney, F.A., Whittaker, A.S., Constantinou, M.C., Kircher, C.A., Johnson, M.W., McNamara, R.J.: Energy dissipation systems for seismic applications: current practice and recent developments. J. Struct. Eng. 134(1), 3–21 (2008)

Tekalur, S.A., Shukla, A., Shivakumar, K.: Blast resistance of polyurea based layered composite materials. Compos. Struct. 84, 271–281 (2008)

Vulcan, M.A., Damian, C., Stanescu, P.O., Vasile, E., Petre, R., Hubca, G.: Polymeric composites based on polyurea matrix reinforced with carbon nanotubes. Mater. Plast. 54(1), 41–44 (2017)

Wang, M.-J.: The role of filler networking in dynamic properties of filled rubber. In: Conference of the Rubber Division, Indianapolis, Indiana, May 5–8, 1998. Am. Chem. Soc., Washington (1998). Paper No. CRP-213-292

Xu, Z.D., Shi, C.F.: Energy dissipation analysis on real application by using viscoelastic dampers. In: The 14th World Conference on Earthquake Engineering, October 12–17, 2008, Bei**g, China (2008)

Yurekli, K., Krishnamoorti, R., Tse, M.F., Mcelrath, K.O., Tsou, A.H., Wang, H.-C.: Structure and dynamics of carbon black-filled elastomers. J. Polym. Sci., Part B, Polym. Phys. 39, 256–275 (2001)

Zhang, J.-F., Yi, X.-S.: Dynamic rheological behavior of high-density polyethylene filled with carbon black. J. Appl. Polym. Sci. 86, 3527–3531 (2002)

Acknowledgements

This research has been funded by King Abdulaziz City of Science and Technology (KACST) under grant number 819-33.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akl, W., Nouh, M., Aldraihem, O. et al. Energy dissipation characteristics of polyurea and polyurea/carbon black composites. Mech Time-Depend Mater 23, 223–247 (2019). https://doi.org/10.1007/s11043-018-9397-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-018-9397-9