Abstract

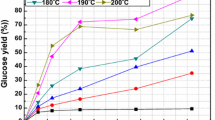

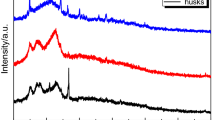

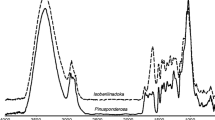

In this work, the thermal decomposition of exhausted sugar beet pulp (ESBP) at a heating rate of 10 °C min−1 and the resulting evolved gases were examined by thermogravimetric (TG) analysis coupled with Fourier transform infrared (FTIR) spectroscopy. The results obtained in the identification of biomass fiber components were compared with those of the Van Soest method. The TG curves obtained in the fast thermal pyrolysis of ESBP exhibited substantial mass loss peaks primarily associated with the decomposition of pectin, hemicellulose and cellulose at 233, 269 and 341 °C, respectively. Lignin, however, was more difficult to decompose since its mass loss occurred over a broad temperature range (200–800 °C). The FTIR spectra obtained at these temperatures were consistent with the formation of large amounts of gases such as CO2, CO, H2O and CH4 in addition to a mixture of organic products including aldehydes, ketones, organic acids, alkanes and phenols. Based on these results, the proposed approach allows lignocellulosic components in exhausted sugar beet pulp biomass to be efficiently screened. Also, the new approach is faster, operationally simpler and more economical than the Van Soest method.

Similar content being viewed by others

References

Matsuo Y, Yanagisawa A, Yamashita Y. A global energy outlook to 2035 with strategic considerations for Asia and Middle East energy supply and demand interdependencies. Energy Strategy Rev. 2013;2:79–91.

Liguori R, Faraco V. Biological processes for advancing lignocellulosic waste biorefinery by advocating circular economy. Biores Technol. 2016;215:13–20.

Mohan SV, Nikhil GN, Chiranjeevi P, Reddy CN, Rohit MV, Kumar AN, Sarkar O. Waste biorefinery models towards sustainable circular bioeconomy: critical review and future perspectives. Biores Technol. 2016;215:2–12.

Villamil JA, Mohedano AF, Rodriguez JJ, Rubia MA. Valorisation of the liquid fraction from hydrothermal carbonisation of sewage sludge by anaerobic digestion. Chem Technol Biotechnol. 2018;93:450–6.

Tripathi M, Sahub JN, Ganesana P. Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew Sustain Energy Rev. 2016;55:467–81.

Casoni AI, Zunino J, Piccolo MC, Volpe MA. Valorization of Rhizoclonium sp. algae via pyrolysis and catalytic pyrolysis. Biores Technol. 2016;216:302–7.

Varma A, Mondal P. Pyrolysis of pine needles: effects of process parameters on products yield and analysis of products. J Therm Anal Calorim. 2018;131:2057–72.

Virmond E, Rocha JD, Moreira RFPM, José HJ. Valorization of agroindustrial solid residues and residues from biofuel production chains by thermochemical conversion: a review, citing Brazil as a case study. Braz J Chem Eng. 2013;30(2):197–229.

González JF, Román S, Encinar JM, Martínez G. Pyrolysis of various biomass residues and char utilization for the production of activated carbons. J Anal Appl Pyrol. 2009;85(1–2):134–41.

Aboudi K, Álvarez-Gallego CJ, Romero-García LI. Improvement of exhausted sugar beet cossettes anaerobic digestion process by co-digestion with pig manure. Energy Fuels. 2015;29(2):754–62.

Aboudi K, Álvarez-Gallego CJ, Romero-García LI. Biomethanization of sugar beet byproduct by semi-continuous single digestion and co-digestion with cow manure. Biores Technol. 2016;200:311–9.

Fundación Española para el Desarrollo de la Nutrición. http://www.fundacionfedna.org/subproductos_fibrosos_humedos/pulpa-de-remolacha (2018). Accessed 25 May 2018.

Van Soest PJ, Robertson JB, Lewis BA. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci. 1991;74(10):3583–97.

Carrier M, Loppinet-Serani A, Denux D, MichelLasnier JM, Ham-Pichavant F, Cansell F, Aymonier C. Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenerg. 2011;35(1):298–307.

Bridgwater AV. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenerg. 2012;38:68–94.

Casoni AI, Hoch PM, Volpe MA, Gutierrez VS. Catalytic conversion of furfural from pyrolysis of sunflower seed hulls for producing bio-based furfuryl alcohol. J Clean Prod. 2018;178:237–46.

Wang P, Zhang J, Shao Q, Wang G. Physicochemical properties evolution of chars from palm kernel shell pyrolysis. J Therm Anal Calorim. 2018;133:1271–80.

Aslan DI, Özoğul B, Ceylan S, Geyikçi F. Thermokinetic analysis and product characterization of medium density fiberboard pyrolysis. Biores Technol. 2018;258:105–10.

Li M, Wang L, Li D, Cheng Y, Adhikari B. Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohyd Polym. 2014;102:136–43.

Colantoni A, Evic N, Lord R, Retschitzegger S, Proto AR, Gallucci F, Monarca D. Characterization of biochar produced from pyrolysis of pelletized agricultural residues. Renew Sustain Energy Rev. 2016;64:187–94.

Memon JR, Memon S, Bhanger MI, Memon GZ, El-Turki A, Allen GA. Characterization of banana peel by scanning electron microscopy and FT-IR spectroscopy and its use for cadmium removal. Colloids Surf B. 2008;66(2):260–5.

Cherian BM, Pothan LA, Nguyen-Chung T, Mennig G, Kottaisamy M, Thomas S. A Novel method for the synthesis of cellulose nanofibril whiskers from banana fibers and characterization. J Agric Food Chem. 2008;56(14):5617–27.

Monsoor MA. Effect of drying methods on the functional properties of soy hull pectin. Carbohyd Polym. 2005;61(3):362–7.

Shen DK, Gu S, Bridgwater AV. Study on the pyrolytic behaviour of xylan-based hemicellulose using TG-FTIR and Py-GC-FTIR. J Anal Appl Pyrol. 2010;87(2):199–206.

Peng Y, Wu S. The structural and thermal characteristics of wheat straw hemicellulose. J Anal Appl Pyrol. 2010;88(2):134–9.

Collard FX, Blin J. A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sustain Energy Rev. 2014;38:594–608.

Patwardhan PR, Dalluge DL, Shanks BH, Brown RC. Distinguishing primary and secondary reactions of cellulose pyrolysis. Bioresour Technol. 2011;102(8):5265–9.

Hosoya T, Kawamoto H, Saka S. Pyrolysis behaviors of wood and its constituent polymers at gasification temperature. J Anal Appl Pyrol. 2007;78(2):328–36.

Tomczak F, Sydenstricker THD, Satyanarayana KG. Studies on lignocellulosic fibers of Brazil. Part II: morphology and properties of Brazilian coconut fibers. Compos A Appl Sci Manuf. 2007;38(7):1710–21.

Liu Q, Zhong Z, Wang S, Luo Z. Interactions of biomass components during pyrolysis: a TG-FTIR study. J Anal Appl Pyrol. 2011;90(2):213–8.

Yang H, Yan R, Chen H, Lee DH, Liang DT, Zheng C. Pyrolysis of palm oil wastes for enhanced production of hydrogen rich gases. Fuel Process Technol. 2006;87(10):935–42.

Ma Z, Chen D, Gu J, Bao B, Zhang Q. Determination of pyrolysis characteristics and kinetics of palm kernel shell using TGA–FTIR and model-free integral methods. Energy Convers Manag. 2015;89:251–9.

Pasangulapati V, Kumar A, Jones CL, Huhnke RL. Characterization of switchgrass, cellulose, hemicellulose and lignin for thermochemical conversions. J Biobased Mater Bioenergy. 2012;6(3):249–58.

Meng A, Zhou H, Qin L, Zhang Y, Li Q. Quantitative and kinetic TG–FTIR investigation on three kinds of biomass pyrolysis. J Anal Appl Pyrol. 2013;104:28–37.

Shaoli G, Yingbo X, Zhenfeng T, Shike S, Lan H, Zhao Z, Yonghua H, Junjie W, Maoqi G, Liusi S. Pyrolysis study of pectin by tunable synchrotron vacuum ultraviolet photoionization mass spectrometry. J Therm Anal Calorim. 2015;120(2):1399–405.

Kaushik A, Singh M. Isolation and characterization of cellulose nanofibrils from wheat straw using steam explosion coupled with high shear homogenization. Carbohyd Res. 2011;346(1):76–85.

Yang H, Yan R, Chen H, Lee DH, Zheng C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel. 2007;86(12–13):1781–8.

Morán JI, Alvarez VA, Cyras VP, Vázquez A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose. 2008;15(1):149–59.

Oudghiri F, Allali N, Quiroga JM, Rodríguez-Barroso MR. TG–FTIR analysis on pyrolysis and combustion of marine sediment. Infrared Phys Technol. 2016;78:268–74.

Oudghiri F, García-Morales JL, Rodríguez-Barroso MR. Novel use of TGA–FTIR technique to predict the pollution degree in marine sediments. Infrared Phys Technol. 2015;72:52–7.

Oudghiri F, García-Morales JL, Allali N, Rodríguez-Barroso MR. Investigation on possible contamination of port sediments by means of ATR–FTIR spectroscopy and thermal analysis. Int J Environ Res. 2014;8(4):1093–104.

Liu Q, Wang S, Zheng Y, Luo Z, Cen K. Mechanism study of wood lignin pyrolysis by using TG–FTIR analysis. J Anal Appl Pyrol. 2008;82(1):170–7.

Yang C, Lu X, Lin W, Yang X, Yao J. TG–FTIR study on corn straw pyrolysis-influence of minerals. Chem Res Chin Univ. 2006;22(4):524–32.

López-Velázquez MA, Santes V, Balmaseda J, Torres-García E. Pyrolysis of orange waste: a thermo-kinetic study. J Anal Appl Pyrol. 2013;99:170–7.

Acknowledgements

The authors are grateful to the University of Cadiz for award of a research grant to the main author. Thanks are also due to Dr. Carlos Alvarez for supplying the sugar pulp biomass and Dr. Luis I. Romero and Ildefonso Caro for their valuable help and access to the Dosi-fiber equipment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sidi-Yacoub, B., Oudghiri, F., Belkadi, M. et al. Characterization of lignocellulosic components in exhausted sugar beet pulp waste by TG/FTIR analysis. J Therm Anal Calorim 138, 1801–1809 (2019). https://doi.org/10.1007/s10973-019-08179-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08179-8