Abstract

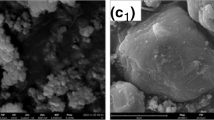

Intumescent flame retardant (FR) system containing acid source, foaming agent and carbonizing agent becomes popular to improve flame suppression. It is still challenging to improve FR performance by directly utilizing polymer matrix as carbonizing agent. Herein, we selected polylactide (PLA) matrix as carbonizing agent, APP encapsulated with melamine formaldehyde (MF) resin (MF@APP) as FR system, and acidic molecular sieve (HZ) as a synergist to improve the flame suppression performance in PLA/MF@APP composites. The APP surfaces were encapsulated with MF particles to protect APP from moisture, which could be supported by scanning electron microscopy (SEM) and Fourier transform infrared spectrometer spectra (FTIR). Temperature-programmed desorption of ammonia (NH3-TPD) measurement proved that HZ particle exhibited more weak and strong acid sites. As an effective synergist, PLA/MF@APP composites with 0.5% synergist exhibit higher (~ 60%) limited oxygen index (LOI) of 28.8% and lower (50%) peak heat release rate (pHRR) of 211 kW/m2 than that of neat PLA. In order to investigate the acidic role of molecular sieve synergist, we exploit neat molecular sieve as a control sample for the comparative study. As a result of protective char layer formation, the total smoke release (TSR) value further decreased from 130.4 to 76.6 m2/m2 in the PLA/MF@APP composites with acidic synergists.

Similar content being viewed by others

References

Zhang Y, **ong ZQ, Ge HD, Ni LK, Zhang T, Huo SQ, Song PA, Fang ZP (2020) Core–shell bioderived flame retardants based on chitosan/alginate coated ammonia polyphosphate for enhancing flame retardancy of polylactic acid. ACS Sustain Chem Eng 8:6402–6412. https://doi.org/10.1021/acssuschemeng.0c00634

He L, Song F, Li DF, Zhao X, Wang XL, Wang YZ (2020) Strong and tough polylactic acid based composites enabled by simultaneous reinforcement and interfacial compatibilization of microfibrillated cellulose. ACS Sustain Chem Eng 8:1573–1582. https://doi.org/10.1021/acssuschemeng.9b06308

Liu T, **g J, Zhang Y, Fang ZP (2018) Synthesis of a novel polyphosphate and its application with APP in flame retardant PLA. RSC Adv 8:4483–4493. https://doi.org/10.1039/c7ra12582h

Wen X, Liu ZQ, Li Z, Zhang J, Wang DY, Szymanska K, Chen XC, Mijowska E, Tang T (2020) Constructing multifunctional nanofiller with reactive interface in PLA/CB-g-DOPO composites for simultaneously improving flame retardancy, electrical conductivity and mechanical properties. Compos Sci Technol 188:107988

** XD, Cui SP, Sun SB, Gu XY, Li HF, Sun J, Zhang S, Bourbigot S (2019) The preparation of an intumescent flame retardant by ion exchange and its application in polylactic acid. ACS Appl Polym Mater 1:755–764. https://doi.org/10.1021/acsapm.8b00278

Wang DY, Song YP, Lin L, Wang XL, Wang YZ (2011) A novel phosphorus-containing poly(lactic acid) toward its flame retardation. Polymer 52:233–238. https://doi.org/10.1016/j.polymer.2010.11.023

Lazar ST, Kolibaba TJ, Grunlan JC (2020) Flame-retardant surface treatments Nature Reviews Materials 5:259–275. https://doi.org/10.1038/s41578-019-0164-6

Tawiah B, Yu B, Fei B (2018) Advances in flame retardant poly(Lactic Acid). Polymers (Basel) 10. https://doi.org/10.3390/polym10080876

Shaw S (2010) Halogenated flame retardants: do the fire safety benefits justify the risks? Rev Environ Health 25:261–306

Zhang S, Yan YX, Wang WJ, Gu XY, Li HF, Li JH, Sun J (2018) Intercalation of phosphotungstic acid into layered double hydroxides by reconstruction method and its application in intumescent flame retardant poly (lactic acid) composites. Polym Degrad Stab 147:142–150. https://doi.org/10.1016/j.polymdegradstab.2017.12.004

Chen XL, Yu J, Guo SY (2006) Structure and properties of polypropylene composites filled with magnesium hydroxide. J Appl Polym Sci 102:4943–4951. https://doi.org/10.1002/app.24938

Horacek H, Grabner R (1996) Advantages of flame retardants based on nitrogen compounds. Polym Degrad Stab 54:205–215

Tian NN, Wen X, Gong J, Ma L, Xue J, Tang T (2013) Synthesis and characterization of a novel organophosphorus flame retardant and its application in polypropylene. Polym Adv Technol 24:653–659. https://doi.org/10.1002/pat.3129

Almeras X, Dabrowski F, Le Bras M, Poutch F, Bourbigot S, Marosi G, Anna P (2002) Using polyamide-6 as charring agent in intumescent polypropylene formulationsI. Effect of the compatibilising agent on the fire retardancy performance. Polym Degrad Stab 77(2):305–313. https://doi.org/10.1016/S0141-3910(02)00068-X

Bras ML, Bugajny M, Lefebvre JM, Bourbigot S (2000) Use of polyurethanes as char-forming agents in polypropylene intumescent formulations. Polym Int 49(10):1115–1124

Fontaine G, Bourbigot S (2009) Intumescent polylactide: A nonflammable material. J Appl Polym Sci 113:3860–3865. https://doi.org/10.1002/app.30379

Zhao X, Chen L, Li DF, Fu T, He L, Wang XL, Wang YZ (2021) Biomimetic construction peanut-leaf structure on ammonium polyphosphate surface: Improving its compatibility with poly(lactic acid) and flame-retardant efficiency simultaneously. Chem Eng J. https://doi.org/10.1016/j.cej.2021.128737

Gao DD, Wen X, Guan YY, Czerwonko W, Li YH, Gao Y, Mijowska E, Tang T (2020) Flame retardant effect and mechanism of nanosized NiO as synergist in PLA/APP/CSi-MCA composites. Compos Commun 17:170–176. https://doi.org/10.1016/j.coco.2019.12.007

Chen JL, Wang JH, Chen HD, Ni AQ, Ding AX (2020) Synergistic effect of intumescent flame retardant and attapulgite on mechanical properties and flame retardancy of glass fibre reinforced polyethylene composites. Compos Struct 246:112404

Qian Y, Wei P, Jiang PK, Li Z, Yan YG, Ji KJ (2013) Aluminated mesoporous silica as novel high-effective flame retardant in polylactide. Compos Sci Technol 82:1–7. https://doi.org/10.1016/j.compscitech.2013.03.019

Wang N, Mi L, Wu YX, Wang XZ, Fang QH (2013) Enhanced flame retardancy of natural rubber composite with addition of microencapsulated ammonium polyphosphate and MCM-41 fillers. Fire Saf J 62:281–288. https://doi.org/10.1016/j.firesaf.2013.09.008

Gu XY, Wang YF, Liu XD, Zhang S, Li HF, Sun J, ** XD, Tang WF (2019) Efficient approach to enhancing the fire resistance of polypropylene by modified microporous aluminosilicate from kaolinite as synergist. Polym Adv Technol 31:1047–1058. https://doi.org/10.1002/pat.4839

Khanal S, Lu YH, Ahmed S, Ali M, Xu SA (2020) Synergistic effect of zeolite 4A on thermal, mechanical and flame retardant properties of intumescent flame retardant HDPE composites. Polym Testing 81:106177

Kaeding W, Chu C, Young L, Weinstein B, Butter S (1981) Selective alkylation of toluene with methanol to produce para-xylene. J Catal 67:159–174

Rahimi N, Karimzadeh R (2011) Catalytic cracking of hydrocarbons over modified ZSM-5 zeolites to produce light olefins: A review. Appl Catal A Gen 398:1–17. https://doi.org/10.1016/j.apcata.2011.03.009

Qiu Y, Wang L, Zhang XW, Liu GZ (2015) Different roles of CNTs in hierarchical HZSM-5 synthesis with hydrothermal and steam-assisted crystallization. RSC Adv 5:78238–78246. https://doi.org/10.1039/c5ra17071k

Zeng S, Xu ST, Gao SS, Gao MB, Zhang WN, Wei YX, Liu ZM (2019) Differentiating diffusivity in different channels of ZSM-5 zeolite by pulsed field gradient (PFG) NMR. ChemCatChem 12:463–468. https://doi.org/10.1002/cctc.201901689

Bourbigot S, Bras ML, Bréant P, Trémillon JM, Delobel R (1996) Zeolites: new synergistic agents for intumescent fire retardant thermoplastic formulations—criteria for the choice of the zeolite. Fire Mater 20:145–154

Felipe RB, Michelle JCR, de Victor OR, Regina SVN, Simone PSR (2019) Synthesis and application of H-ZSM-5 zeolites with different levels of acidity as synergistic agents in flame retardant polymeric materials. Polymers (Basel) 11(12):2110. https://doi.org/10.3390/polym11122110

Feng XM, Wei JL, Yin B, Yang MB (2012) Properties of flame retardant polypropylene with melamine-formaldehyde resin microencapsulated ammonium polyphosphate. China Synthetic Resin and Plastics 29(02):16–19

Groen JC, Peffer LAA, Moulijn JA, Perez-Ramirez J (2004) Mesoporosity development in ZSM-5 zeolite upon optimized desilication conditions in alkaline medium. Colloid Surf A-Physicochem Eng Asp 241:53–58. https://doi.org/10.1016/j.colsurfa.2004.04.012

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Chai YQ, Zhao TB, Gao X, Zhang JJ (2018) Low cracking ratio of paraffin microcapsules shelled by hydroxyl terminated polydimethylsiloxane modified melamine-formaldehyde resin. Colloid Surf A-Physicochem Eng Asp 538:86–93. https://doi.org/10.1016/j.colsurfa.2017.10.078

Zhou YX, Cui YX, Wang X, Zhang M, Gao YY, Wang HY (2021) Melamine-formaldehyde microcapsules encapsulating HEDP for sustained scale inhibition. Colloid Surf A-Physicochem Eng Asp 628:127361

Calzaferri G, Huber S, Maas H, Minkowski C (2003) Host–guest antenna materials. Angew Chem Int Ed 42(32):3732–3758

Ma Q, Fu TJ, Wang YJ, Li H, Cui LP, Li Z (2020) Development of mesoporous ZSM-5 zeolite with microporosity preservation through induced desilication. J Mater Sci 55:11870–11890. https://doi.org/10.1007/s10853-020-04855-5

Rodríguez-González L, Hermes F, Bertmer M, Rodríguez-Castellón E, Jiménez-López AU (2007) The acid properties of H-ZSM-5 as studied by NH3-TPD and 27Al-MAS-NMR spectroscopy. Appl Catal A 328:174–182. https://doi.org/10.1016/j.apcata.2007.06.003

Groen JC, Moulijn JA, Pérez-Ramírez J (2005) Decoupling mesoporosity formation and acidity modification in ZSM-5 zeolites by sequential desilication–dealumination. Microporous Mesoporous Mater 87:153–161. https://doi.org/10.1016/j.micromeso.2005.07.050

Liu XD, Guo J, Tang WF, Li HF, Gu XY, Sun J, Zhang S (2019) Enhancing the flame retardancy of thermoplastic polyurethane by introducing montmorillonite nanosheets modified with phosphorylated chitosan. Compos Part a-Appl S 119:291–298. https://doi.org/10.1016/j.compositesa.2019.02.009

Xu WZ, Wang XL, Wu Y, Li W, Chen CY (2019) Functionalized graphene with Co-ZIF adsorbed borate ions as an effective flame retardant and smoke suppression agent for epoxy resin. J Hazard Mater 363:138–151. https://doi.org/10.1016/j.jhazmat.2018.09.086

Tawiah B, Zhou YY, Yuen RKK, Sun J, Fei B (2020) Microporous boron based intumescent macrocycle flame retardant for poly (lactic acid) with excellent UV protection. Chem Eng J 402:126209. https://doi.org/10.1016/j.cej.2020.126209

Yan HW, Wei JL, Yin B, Yang MB (2015) Effect of the surface modification of ammonium polyphosphate on the structure and property of melamine–formaldehyde resin microencapsulated ammonium polyphosphate and polypropylene flame retardant composites. Polym Bull 72:2725–2737

**ong ZQ, Zhang Y, Du XY, Song PA, Fang ZP (2019) Green and scalable fabrication of core–shell biobased flame retardants for reducing flammability of polylactic acid. ACS Sustain Chem Eng 7:8954–8963. https://doi.org/10.1021/acssuschemeng.9b01016

Acknowledgements

We appreciate the funding support from the Ningxia Key R&D plan, the open project of State Key Laboratory of High-efficiency Utilization of Coal and Green Chemical Engineering and First-class discipline construction (Chemical Engineering and Technology) in Ningxia University (Grant/Award Numbers are 2020BDE03004, 2020BEG03037, 2019-KF-17 and NXYLXK2017A04, respectively).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ma, Q., Lu, J., Yao, J. et al. The synergistic role of acidic molecular sieve on flame retardant performance in PLA/MF@APP composite. J Polym Res 29, 192 (2022). https://doi.org/10.1007/s10965-022-03037-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03037-y