Abstract

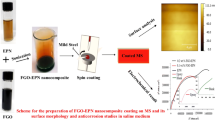

Garcinia gummigutta vegetable oil (GGVO) is a rich source of stearic and oleic acid which on heat treatment at around 300 °C, will get polymerized with highly conjugated network system. The present work intended to exploit the properties of GGVO for the production of eco-friendly anti-corrosion coating material. The oil extracted from GG seeds was used to prepare graphene oxide (GO) dispersion in oil and successfully employed as an efficient anti-corrosion coating material on mild steel (MS). All coatings are done by simple heat treatment of dip-coated MS specimen. The corrosion prevention ability of the coating was studied by potentiodynamic polarization and electrochemical impedance spectroscopy techniques in 3.5% NaCl solution. Electrochemical results showed that the addition of GO significantly enhances the corrosion inhibition performance of the GGVO coating. The inhibition efficiency of the GGVO coating increased from 93.0 to 99.8% on the incorporation of 0.3 wt% of GO into the oil. The enhancement of the corrosion prevention ability of the GO ink is discussed based on the impermeable action of GO to the corrosive ions and also suppression of the number of pores in the polymer that is formed during the curing of the coating.

Graphic Abstract

Similar content being viewed by others

References

Armelin E, Pla R, Liesa F (2008) Corros Sci 50:721–728

Husain E, Narayanan TN, Taha-Tijerina JJ (2013) ACS Appl Mater Interfaces 5:4129–4135

Chen L, Zhou S, Song S, Zhang B, Gu G (2011) J Coat Technol Res 8:481–487

Liu Y, Sun D, You H, Chung JS (2005) Appl Surf Sci 246:82–89

Yu D, Tian J, Dai J, Wang X (2013) Electrochim Acta 97:409–419

Gao W, Li Z (2004) Mater Res 7:175–182

Kirkland NT, Schiller T, Medhekar N, Birbilis N (2012) Corros Sci 56:1–4

Chen S, Brown L, Levendorf M (2011) ACS Nano 5:1321–1327

Chang KC, Hsu MH, Lu HI (2014) Carbon N Y 66:144–153

Mondal J, Marques A, Aarik L, Kozlova J, Simoes A, Sammelselg V (2016) Corros Sci 105:161–169

Yoo BM, Shin HJ, Yoon HW, Park HB (2014) J Appl Polym Sci 131:1–23

Su Y, Kravets VG, Wong SL (2014) Nat Commun 5:1–5

Chaudhry AU, Mittal V, Mishra B (2015) Mater Chem Phys 163:130–137

**e W, Huang M (2018) Energy Convers Manag 159:42–53

Comlekci GK, Ulutan S (2019) Prog Org Coat 129:292–299

Miao S, Wang P, Su Z, Zhang S (2014) Acta Biomater 10:1692–1704

Alam M, Alandis NM (2011) J Polym Environ 19(2):391–397

Balakrishnan T, Sathiyanarayanan S, Mayavan S (2015) ACS Appl Mater Interfaces 7:19781–19788

Singhbabu YN, Sivakumar B, Singh JK (2015) Nanoscale 7:8035–8047

Choppa T, Selvaraj CI, Zachariah A (2015) J Food Sci Technol 52(9):5906–5913

Parthasarathy U, Nandakishore OP, Senthil Kumar R, Parthasarathy VA (2014) J Glob Biosci 3(6):872–880

Narasimharao K, Venkata Ramana G, Sreedhar D, Vasudevarao V (2016) J Mater Sci Eng 5:284. https://doi.org/10.4172/2169-0022.1000284

Sims RPA (1957) J Am Oil Chem Soc 34(9):466–469

Wang C, Erhan S (1999) J Am Oil Chem Soc 76:1211–1216

Guner FS (1997) J Am Oil Chem Soc 74:1525–1529

Brioude MM, Guimaraes DH, Fiuza RP, Prado LASA, Boaventura JS, Jose NM (2007) Mater Res 10(4):335–339

Pakhomov P, Khizhnyak S, Tshmel A (2010) Laser Phys 20:936–947

Pakhomov P, Khizhnyak S, Galitsyn V, Rogova E, Hartmann B, Tshmel A (2011) Macromol Symp 305(1):63–72

Emran MY, Shenashen MA, Morita H, El-Safty SA (2018) Adv Healthc Mater 7(16):1701459

Emran MY, Shenashen MA, Abdelwahab AA, Khalifa H, Mekawy M, Akhtar N, Abdelmottaleb M, El-Safty SA (2018) J Appl Electrochem 48(5):529–542

Shi X, Nguyen TA, Suo Z (2009) Surf Coat Technol 204:237–245

Liang G, Schmauder S, Lyu M, Schneider Y, Zhang C, Han Y (2018) Materials (Basel) 11(2):237

Siu JHW, Li LKY (2000) Wear 237:283–287

Li J, Ecco L, Delmas G, Whitehouse N, Collins P, Deflorian F, Pan J (2014) J Electrochem Soc 162:55–63

Almansour A, Azizi M, Jesri AM, Entakly S (2015) Int J Acad Sci Res 3:37–45

Li W, Li DY (2006) Acta Mater 54:445–452

Han D, Yan L, Chen W, Li W (2011) Carbohydr Polym 83:653–658

Sangaj NS, Malshe VC (2004) Prog Org Coat 50:28–39

Yuan S, Pehkonen SO, Liang B, Ting YP, Neoh KG, Kang ET (2011) Corros Sci 53:2738–2747

Lorenz WJ (1981) Corros Sci 21:647–672

Palimi MJ, Rostami M, Mahdavian M, Ramezanzadeh B (2015) J Coat Technol Res 12:277–292

Ramezanzadeh B, Niroumandrad S, Ahmadi A, Mahdavian M, Moghadam MM (2016) Corros Sci 103:283–304

Mansfeld F (1990) Electrochim Acta 35(10):1533–1544

Alsamuraee A, Jaafer H (2011) Am J Sci Ind Res 2:761–768

Mayavan S, Siva T, Sathiyanarayanan S (2013) RSC Adv 3:24868–24871

Yu YH, Lin YY, Lin CH, Chan CC, Huang YC (2014) Polym Chem 5:535–550

Gomez-Aguilar JF, Escalante-Martinez JE, Calderon-Ramon C, Morales-Mendoza LJ, Benavidez-Cruz M, Gonzalez-Lee M (2016) Adv Math Phys 2016, Article ID 9720181

Dhoke SK, Rajgopalan N, Khanna AS (2012) Int J Mater Sci 2:47–55

Nayak SR, Mohana KNS (2018) Surf Interfaces 11:63–73

Yu D, Tian J, Dai J, Wang X (2014) Corrosion 70:329–336

Chaitra TK, Mohana KNS, Tandon HC (2015) J Mol Liq 211:1026–1038

Acknowledgements

The corresponding author and co-authors acknowledges Institution of Excellence and Center for Material Science and Technology, University of Mysore, Mysuru, India, for the instrumentation facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The corresponding author and co-authors declared that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hegde, M.B., Nayak, S.R., Mohana, K.N.S. et al. Garcinia gummigutta Vegetable Oil–Graphene Oxide Nano-composite: An Efficient and Eco-friendly Material for Corrosion Prevention of Mild Steel in Saline Medium. J Polym Environ 28, 483–499 (2020). https://doi.org/10.1007/s10924-019-01611-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01611-y