Abstract

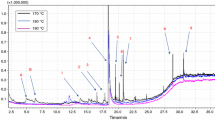

Polymer blends between lignin, a natural, widely available, no-cost material, and Poly(ε-caprolactone) (PCL), a biodegradable polymer, have been prepared using the ‘clean’, friendly to the environment, technique of the High Energy Ball Milling (HEBM). Two kinds of lignin have been used, Straw lignin, obtained through the Steam Explosion process (SE lignin), and/or Lignosulphonated one (LS lignin). The tensile mechanical tests have shown that, at certain specific compositions, the blends, in particular those with both SE and LS lignin, have good mechanical properties. In particular, by varying the blend composition it is possible to obtain materials with tuneable properties, therefore useful for different applications. Dynamic-Mechanical-Thermal Analysis (DMTA) reveals substantial immiscibility of the blends. Experiments of UV irradiation show that lignin acts as an UV stabilizer for PCL. The effect is higher with SE lignin, likely due to its low molecular weight, which allows the short lignin chains to diffuse more easily within the amorphous regions of PCL.

Similar content being viewed by others

References

Glasser WG, Sarkanen S (1989) Lignin: properties and materials. ACS Symposium Series 398, American Chemical Society, Washington DC

Mai C, Majcherczyk A, Schormann W, Hüttermann A (2002) Polym Degrad Stab 75:107

Mai C, Milstein O, Huttermann A (2000) J Biotechnol 79:173

Meister JJ, Damodar RP, Harvey C (1984) J Appl Polym Sci 29:3457

Meister JJ, Chen MJ (1991) Macromolecules 24:6843

Meister JJ, Chen MJ (1993) J Appl Polym Sci 49:935

Chen M-J, Gunnells DW, Gardner DJ, Milstein O, Gersonde R, Feine HJ, Huttermann A, Frund R, Ludemann HD, Meister JJ (1996) Macromolecules 29:1389

De Oliveira W, Glasser WG (1994) Macromolecules 27:5

Kadla JF, Kubo S (2004) Composites Part A: Appl Sci Manufact 35:395

Koikova A, Podstranka G (2000) Polymer 41:4901

Pucciariello R, Villani V, Bonini C, D’Auria M, Vetere T (2004) Polymer 45:4159

Kadla JF, Kubo S (2003) Macromolecules 4:561

Kubo S, Kadla JE (2004) Macromolecules 37:6904

Kubo S, Kadla JF (2005) J Appl Polym Sci 98:1437

Li Y, Sarkanen S (2002) Macromolecules 35:9707

Kubo S, Kadla JF (2003) Biomacromolecules 4:561

Corradini E, Pineda EAG, Hechleitner AAW (1999) Polym Degrad Stab 66:199

El Raghi S, Zahran RR, Gebril BE (2000) Mater Lett 46:332

Bonini C, D’Auria M, Mauriello G, Pucciariello R, Teghil R, Tofani D, Viggiani L, Viaggiano D, Zimbardi F (2001) J Appl Polym Sci 79:72

Bonini C, D’Auria M, Ferri R, Pucciariello R, Sabia A (2003) J Appl Polym Sci 90:1163

Bonini C, D’Auria M, Emanuele L, Ferri R, Pucciariello R, Sabia A (2005) J Appl Polym Sci 98:1451

Pucciariello R, Bonini C, D’Auria M, Villani V, Giammarino G, Gorrasi G (2008) J Appl Polym Sci 109:309

Rowlands SA, Hall AK, Mc Cormick PG, Street R, Hart RJ, Ebell GF et al (1994) Nature 22:367

Shaw WJD (1998) Mater Sci Forum 19:269

Magini M, Bugio N, Iasonna A, Martelli S, Padella F, Paradiso E (1993) J Mater Synth Proc 3:1

Sorrentino A, Gorrasi G, Tortora M, Vittoria V, Costantino U, Marmottini F, Padella F (2005) Polymer 46:1601

Shulga G, Kalyuzhnava R, Zezin A, Kabanov V (2002) Cellulose Chem Technol 36:225

Bamford CH, Norrish RGW (1935) J Chem Soc 1504

Ikada E (1997) J Photopol Technol 10:265

Tsuji H, Echizen Y, Nishimura Y (2006) Polym Degrad Stab 91:1128

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pucciariello, R., D’Auria, M., Villani, V. et al. Lignin/Poly(ε-Caprolactone) Blends with Tuneable Mechanical Properties Prepared by High Energy Ball-Milling. J Polym Environ 18, 326–334 (2010). https://doi.org/10.1007/s10924-010-0212-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-010-0212-1