Abstract

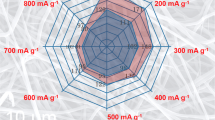

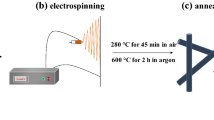

Metal oxide nanofibers are prepared by electrospinning and are developed to be the electrodes for lithium-ion batteries (LIBs). The effect of calcination temperature and the Li:Co mole ratio of LiCoO2 nanofibers was investigated on the electrochemical cathode performance in a coin cell battery. The higher temperature calcination and Li:Co mole ratio have improved the electrochemical performance of the nanofibers. Lithium cobalt oxide (LiCoO2) nanofibers obtained at 400 and 700 °C retain 65% and 90% of the initial capacity, respectively, after the high-current test and the C-rate reverted to 0.1 C. When doubling the mole ratio of Li:Co (2:1), an increase in specific capacity values from 78 to 148 mAh g−1 has been provided. Additionally, colloidal titania nanoparticles (TiO2 NPs)-doped LiCoO2 nanofibers were obtained and investigated as a cathode material. While the increment in calcination temperature results in higher crystallinity and stability of the LiCoO2 phase, in the presence of the TiO2 NPs causes a transformation of binary (LiCoO2/TiO2) to ternary Li-based transition metal oxide (Li2CoTi3O8/TiO2). An initial discharge capacity of 82 mAh g−1 was found at 0.1 C for the Li2CoTi3O8/TiO2 nanoparticles and the capacity retention was 83% when returned to 0.1 C after 25 cycles.

Similar content being viewed by others

References

H. Li, Z. Wang, L. Chen, X. Huang, Adv. Mater. 21, 45 (2009)

H. Wang, H. Dai, Chem. Soc. Rev. 42, 7 (2013)

J.-W. Jung, C.-L. Lee, S. Yu, I.-D. Kim, J. Mater. Chem. A 4, 3 (2016)

R. Yazami, Nanomaterials for lithium-ion batteries: fundamentals and applications, 1st edn. (Jenny Stanford Publishing, New York, 2013), pp. 139–165

A. Shukla, T.P. Kumar, Curr. Sci. 94, 3 (2008)

N. Nitta, F. Wu, J.T. Lee, G. Yushin, Mater. Today 18, 5 (2015)

Y.G. Guo, J.S. Hu, L.J. Wan, Adv. Mater. 20, 15 (2008)

X. Kong, R. Zhou, J. Wang, J. Zhao, A.C.S. Appl, Energy Mater. 2, 7 (2019)

L. de Biasi, A. Schiele, M. Roca-Ayats, G. Garcia, T. Brezesinski, P. Hartmann, J. Janek, Chemsuschem 12, 10 (2019)

M.M. Thackeray, S.-H. Kang, C.S. Johnson, J.T. Vaughey, R. Benedek, S. Hackney, J. Mater. Chem. 17, 30 (2007)

M. Büyükyazi, S. Mathur, Nano Energy 13, 28–35 (2015)

G.-N. Zhu, Y.-G. Wang, Y.-Y. **a, Energy Environ. Sci. 5, 5 (2012)

J. Liu, X. Wei, F. Meng, Advanced battery materials, 1st edn. (Wiley VCH, Weinheim, 2019), pp. 87–157

Y. Wang, G. Cao, Adv. Mater. 20, 12 (2008)

Y. Tang, L. Yang, Z. Qiu, J.S. Huang, Electrochem. Commun. 10, 10 (2008)

H. Kawai, M. Tabuchi, M. Nagata, H. Tukamoto, A.R. West, J. Mater. Chem. 8, 5 (1998)

Z. Liu, X. Zhou, Graphene: energy storage and conversion applications (CRC Press, Boca Raton, 2014), pp. 65–13

J.-G. Kim, D. Shi, K.-J. Kong, Y.-U. Heo, J.H. Kim, M.R. Jo, Y.C. Lee, Y.-M. Kang, S.X. Dou, A.C.S. Appl, Mater. Interfaces 5, 3 (2013)

S.Y. Liu, C.Y. Fan, H.C. Wang, J.P. Zhang, X.L. Wu, Chem. Eur. J. 23, 36 (2017)

D.H. Doughty, E.P. Roth, Electrochem. Soc. Interface 21, 2 (2012)

Y. Gu, D. Chen, X. Jiao, J. Phys. Chem. B 109, 38 (2005)

X. Zhang, L. Ji, O. Toprakci, Y. Liang, M. Alcoutlabi, Polym. Rev. 51, 3 (2011)

A.F. Ismail, N. Hilal, J. Jaafar, C. Wright, Nanofiber membranes for medical, environmental, and energy applications (CRC Press, Boca Raton, 2019), pp. 215–235

W. Chee, H. Lim, Z. Zainal, I. Harrison, N. Huang, Y. Andou, K. Chong, A. Pandikumar, RSC Adv. 7, 20 (2017)

S. Santangelo, Appl. Sci. 9, 6 (2019)

C.T. Lim, Prog. Polym. Sci. 70, 1–17 (2017)

X. Shi, W. Zhou, D. Ma, Q. Ma, D. Bridges, Y. Ma, A. Hu, J. Nanomater. 16, 1 (2015)

N. Horzum, R. Muñoz-Espí, G. Glasser, M.M. Demir, K. Landfester, D. Crespy, A.C.S. Appl, Mater. Interfaces 4, 11 (2012)

N. Sebastian, B. George, B. Mathew, Polym. Degrad. Stab. 60, 2–3 (1998)

B. Jaquet, D. Wei, B. Reck, F. Reinhold, X. Zhang, H. Wu, M. Morbidelli, Colloid Polym. Sci. 291, 7 (2013)

L. Li, Y.-L. Hsieh, Polymer 46, 14 (2005)

S.A. Simakov, Y. Tsur, J. Nanopart. Res. 9, 3 (2007)

N. Daels, M. Radoicic, M. Radetic, S.W. Van Hulle, K. De Clerck, Sep. Purif. Technol. 133, 282e290 (2014)

M. Catauro, E. Tranquillo, G. Dal Poggetto, M. Pasquali, A. Dell’Era, S. Vecchio Ciprioti, Materials 11, 12 (2018)

M. Krissanasaeranee, T. Vongsetskul, R. Rangkupan, P. Supaphol, S. Wongkasemjit, J. Am. Ceram. Soc. 91, 9 (2008)

J.I. Langford, A. Wilson, J. Appl. Crystallogr. 11, 2 (1978)

J. Wang, H. Zhao, Y. Shen, Z. Du, X. Chen, Q. **a, ChemPlusChem 78, 12 (2013)

S. Pinilla, A. Machín, S.-H. Park, J.C. Arango, V. Nicolosi, F. Márquez-Linares, C. Morant, J. Phys. Chem. B 122, 2 (2017)

G. Ning, B. Haran, B.N. Popov, J. Power Sour. 117, 160–169 (2003)

T.-F. Yi, Y. **e, J. Shu, Z. Wang, C.-B. Yue, R.-S. Zhu, H.-B. Qiao, J. Electrochem. Soc. 158, 3 (2011)

Y. Ou, J. Wen, H. Xu, S. **e, J. Li, J. Phys. Chem. Solids 74, 322–327 (2013)

Y. Mizuno, E. Hosono, T. Saito, M. Okubo, D. Nishio-Hamane, K. Oh-ishi, T. Kudo, H. Zhou, J. Phys. Chem. C 116, 19 (2012)

H.G. Wang, S. Yuan, D.L. Ma, X.B. Zhang, J.M. Yan, Energy Environ. Sci. 8, 1660–1681 (2015)

Z. Hong, X. Zheng, X. Ding, L. Jiang, M. Wie, and K. Wie, Energy Environ. Sci. 4 (2011)

Y. Yu, Y. Liu, X. Yang, in Alkali-Ion Batteries, ed. by D. Yang (IntechOpen, London, 2016), pp. 111–125

C. Daniel, D. Mohanty, J. Li, D.L. Wood, AIP Conf. Proc. 1597, 26 (2014)

X. Feng, Nanocarbons for Advanced Energy Storage (Wiley, Hoboken, 2015), pp. 59–87

Acknowledgements

The authors gratefully acknowledge the financial support from the Izmir Katip Celebi University Scientific Research Project 2014-1-MÜH-15. The authors also thank Dr. Davut Uzun for the electrochemical measurements. Iztech Center for Materials Research is also acknowledged for SEM micrographs.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kap, Ö., Inan, A., Er, M. et al. Li-ion battery cathode performance from the electrospun binary LiCoO2 to ternary Li2CoTi3O8. J Mater Sci: Mater Electron 31, 8394–8402 (2020). https://doi.org/10.1007/s10854-020-03374-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03374-y