Abstract

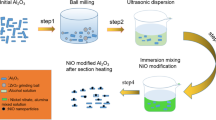

The addition of Al2O3 nanoparticles with 0.01, 0.03, 0.05, 0.07, and 0.1 wt% to eutectic solder Sn–3.5Ag was studied so as to be aware of the influence of Al2O3 addition as the particulate reinforcement to the microstructure, microhardness, and mechanical properties. By adding 0.1 wt% Al2O3 nanoparticles, the intermetallic compounds (IMCs; Ag3Sn) decreased from 95.55 to 45.22 nm. Additionally, the IMCs growth rates diminished by 30% to the plain solder. As a whole, the Al2O3 nanoparticles-embedded solder displayed better properties than plain solder in micro-creep and microhardness. Al2O3 nanoparticles fixed in the lead-free solder matrix impede the movement of dislocations by sticking and also stuck grain boundaries so as to enhance the mechanical properties of the lead-free solder matrix. The Sn–3.5Ag/Al2O3 lead-free solder showed improved properties compared with the traditional solder Sn63Pb37, which could substitute some Pb holding solder alloys in micro-electronic components and interconnections. The Scanning Electron Microscope (SEM) was carried out to study the morphology of the fabricated solders. The SEM revealed that the microstructure of solders was improved by do** Al2O3. According to X-ray diffraction analysis, the β-Sn (tetragonal phase) was formed as the main phase for all solders in addition to the peaks related to some intermetallic compound phase Ag3Sn. The results indicated that higher mechanical properties were obtained for composite solder Sn–3.5Ag/Al2O3 compared with plain solder. The melt-spun process is more resistant to indentation creep.

Similar content being viewed by others

References

M. Rette, P. Lombeacht, B. Kemp, M. Graff, High melting Pb-free solder alloys for die-attach applications. Adv. Eng. Mater. 7(10), 965 (2005)

A.K. Gian, Y.C. Chan, A. Sharif, N.B. Wong, W.K.C. Yung, Interfacial microstructure and shear strength of Ag nano particle doped Sn–9Zn solder in ball grid array packages. Microelectron. Reliab. 746, 49 (2009)

M.N. Islam, Y.C. Chan, A. Sharif, Rizvil MJ (2005) Effect of 9wt% in addition to Sn–3.5Ag–0.5Cu solder on the interfacial reaction with the Au/Nip metallization on Cu pads. J. Alloys Compd. 396, 217 (2005)

A.K. Gian, Y.C. Chan, W.K.C. Yung, Effect of nano Ni additions on the structure and properties of Sn–9Zn and Sn–Zn–3Bi solders in Au/Ni/Cu ball grid array packages. Mater. Sci. Eng. B 92, 162 (2009)

R.M. Shalaby, Effect of rapid solidification on mechanical properties of a lead free Sn–3.5Ag solder. J. Alloys Compd. 505(1), 113 (2010)

R.M. Shalaby, Effect of silicon addition on mechanical and electrical properties of Sn–Zn based alloys rapidly quenched from melt. Mater. Sci. Eng. A 112, 550 (2012)

R.M. Shalaby, Effect of silver and indium addition on mechanical properties and indentation creep behavior of rapidly solidified Bi–Sn based lead-free solder alloys. Mater. Sci. Eng. A 86, 560 (2013)

R.M. Shalaby, Indium, chromium and nickel-modified eutectic Sn–0.7wt% Cu lead–free solder rapidly solidified from molten state. J. Mater. Sci.: Mater. Electron. 26(9), 6625 (2015)

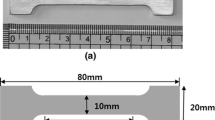

R.M. Shalaby, M. Kamal, E.A.M. Ali, M.S. Gumaan, Microstructural and mechanical characterization of melt–spun process Sn–3.5Ag and Sn–3.5Ag–xCu lead–free solders for low cost electronic assembly. Mater. Sci. Eng. A 690, 446 (2017)

G. Ghosh, Interfacial reaction between multicomponent lead free solders and Ag, Cu, Ni and Pd substrates. J. Electron. Mater. 33(10), 1080 (2004)

M.N. Islam, Y.C. Chan, M.J. Rizvil, W. Jellek, Investigations of interfaced reactions of Sn–Zn based and Sn–Ag–Cu lead–free solder alloys as replacement for Sn–Pb solder. J. Alloys Compd. 136, 400 (2005)

T. Ichitsubo, E. Matsubara, K. Ugiwara, M. Yomaguchi, H. Irie, S. Kumamoto et al., Control of compound forming reaction at the interface between Sn–Zn solder and Cu substrate. J. Alloys Compd. 392, 200 (2005)

J. Shen, Y.C. Liu, Han YJ, Tian YM, Gao HX, Strengthening effects of ZrO2 nanoparticles on the microstructure and microhardness of Sn–3.5Ag lead-free solder. Mater. Sci. Eng. A 441, 135 (2006)

Z.X. Li, M. Gupta, High strength lead–free composite solder materials using hypoeutectic Sn–Zn as lead–free solder. Mater. Lett. 655, 61 (2007)

J. Shen, Y.C. Chan, Effects of ZrO2 nanoparticles on the mechanical properties of Sn–Zn solder joints on Au/Ni/Cu pads. J. Alloys Compd. 477(1–2), 552 (2009)

M.S. Gumaan, R.M. Shalaby, E.A.M. Ali, M. Kamal, Copper effects in mechanical, thermal and electrical properties of rapidly solidified eutectic Sn–Ag alloy. J. Mater. Sci.: Mater. Electron. 29(11), 8886–8894 (2018)

R.M. Shalaby, M. Kamal, E.A.M. Ali, M.S. Gumaan, Design and properties of new lead-free solder joints using Sn-3.5Ag-Cu solder. Silicon J. 10(5), 1861–1871 (2018)

G. Ren, I.J. Wilding, M.N. Collins, Alloying influences on low melt temperature SnZn and SnBi solder alloys for electronic interconnections. J. Alloys Compd. 251, 665 (2016)

L.C. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, C.H. Chiang, Effects of nano–Al2O3 additions on microstructure development and hardness of Sn3.5Ag0.5Cu solder. Mater. Des. 31, 4831 (2010)

A. Yakymovych, Y. Plevachuk, P. Švec Sr., D. Janičkovič, P. Šebo, N. Beronská, M. Nosko, L. Orovcik, A. Roshanghias, H. Ipser, Nanocomposite SAC solders: morphology, electrical and mechanical properties of Sn–3.8Ag–0.7Cu solders by adding Co nanoparticles. J. Mater. Sci.: Mater. Electron. 28, 10965 (2017)

E. Schreiber, O.L. Anderson, N. Soga (1973) Elastic Constant and Their Measurements. (McGraw–Hill, New York, 1973), p. 82.

S. Timoshenko, J. N. Goddier, Theory of Elasticity, 2nd edn. (McGraw–Hill, New York, 1951), p. 277.

T.R. Bieler, H. Jiang, Influence of Sn grain size and orientation on the thermo mechanical response and reliability of Pb–free solder joints. IEEE Trans. Compd. Packag. Technol. 31(2), 1462 (2006)

B.D. Cullity, Elements of X-ray Diffraction, 2nd edn. (Addision-Wesely, Boston, 1978), p. 248

D.Q. Yu, J. Zhao, L. Wang, Improvement on the microstructure stability, mechanical and wetting properties of Sn–Ag–Cu lead-free solder with the addition of rare earth elements. J. Alloys Compd. 376, 170–175 (2004)

R.M. Shalaby, Effect of indium content and rapid solidification on microhardness and micro–creep of Sn–Zn eutectic lead free solder alloy. Cryst. Res. Technol. 45(4), 427 (2010)

Z. Zhu, Y.C. Chan, C. Zhong, C.L. Gan, F. Wu, Effect of the size of carbon nanotubes (CNTs) on the microstructure and mechanical strength of CNTs-doped composite Sn0.3Ag0.7Cu-CNTs solder. Mater. Sci. Eng. A 160, 727 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shalaby, R.M., Elzanaty, H. Effect of nano-Al2O3 particles on the microstructure and mechanical performance of melt-spun process Sn–3.5Ag composite solder. J Mater Sci: Mater Electron 31, 5907–5913 (2020). https://doi.org/10.1007/s10854-019-02821-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02821-9