Abstract

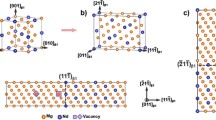

Nanoscale δ′/θ′/δ′ composite precipitate, as another important strengthening phase in the latest generation of Al–Li alloys, exhibits excellent resistance to coarsening. Here, we propose two thickening models for an anomalous δ′/θ′/δ′ that is discovered recently, by analyzing various influencing factors, including the static energy barrier, aging temperature-dependent nucleation conditions, and the elastic distortion suffered during growth. It indicates that the thickness of the δ′/θ′/δ′ composite precipitate seems to depend on the nucleation of the δ′. At elevated aging temperatures, θ′ precipitates can grow and thicken rapidly until the δ′ nucleates on them. This is strikingly different from the dislocation-induced growth mechanism. Subsequently, we propose a vacuum-added methodology to accurately extract the interfacial energy. The results show that this nano-composite precipitate can realize supra-nanostructure in thickness at low aging temperatures due to the spontaneous nucleation of the δ′ upon the pre-precipitate θ′. Cu atoms segregated at the interface suppress the nucleation of the δ′, but release the lattice distortion to some extent. Using Griffith fracture model-assisted ab-initio uniaxial tensile tests, the cohesion strength and fracture process of this composite precipitate with and without Cu segregation have been captured. It indicates that the Cu atoms induced interfacial expansion and the fracture of strong Al–Al covalent bond, resulting in a reduction of fracture strength of this nano-composite precipitate.

Similar content being viewed by others

References

Dorin T, Vahid A, Lamb J (2018) Chapter 11: aluminium lithium alloys. In: Lumley RN (ed) Fundamentals of aluminium metallurgy. Woodhead Publishing, Cambridge, pp 387–438. https://doi.org/10.1016/B978-0-08-102063-0.00011-4

Jiang B, Wang HS, Yi DQ, Tian Y, Shen FH, Wang B, Liu HQ, Hu Z (2020) Effect of Ag addition on the age hardening and precipitation behavior in an Al–Cu–Li–Mg–Zn–Mn–Zr alloy. Mater Charact 162:110184. https://doi.org/10.1016/j.matchar.2020.110184

Ma PP, Zhan LH, Liu CH, Wang Q, Li H, Liu DB, Hu ZG (2019) Pre-strain-dependent natural ageing and its effect on subsequent artificial ageing of an Al–Cu–Li alloy. J Alloys Compd 790:8–19. https://doi.org/10.1016/j.jallcom.2019.03.072

Kim K, Zhou BC, Wolverton C (2018) First-principles study of crystal structure and stability of T1 precipitates in Al–Li–Cu alloys. Acta Mater 145:337–346. https://doi.org/10.1016/j.actamat.2017.12.013

Gumbmann E, Lefebvre W, De Geuser F, Sigli C, Deschamps A (2016) The effect of minor solute additions on the precipitation path of an Al–Cu–Li alloy. Acta Mater 115:104–114. https://doi.org/10.1016/j.actamat.2016.05.050

Miao J, Sutton S, Luo AA (2020) Microstructure and hot deformation behavior of a new aluminium–lithium–copper based AA2070 alloy. Mater Sci Eng A 777:139048. https://doi.org/10.1016/j.msea.2020.139048

Duan SY, Wu CL, Gao Z, Cha LM, Fan TW, Chen JH (2017) Interfacial structure evolution of the growing composite precipitates in Al–Cu–Li alloys. Acta Mater 129:352–360. https://doi.org/10.1016/j.actamat.2017.03.018

Duan SY, Le Z, Chen ZK et al (2016) Li-atoms-induced structure changes of Guinier–Preston–Bagaryatsky zones in AlCuLiMg alloys. Mater Charact 121:207–212. https://doi.org/10.1016/j.matchar.2016.09.037

Yoshimura R, Konno TJ, Abe E, Hiraga K (2003) Transmission electron microscopy study of the early stage of precipitates in aged Al–Li–Cu alloys. Acta Mater 51:2891–2903. https://doi.org/10.1016/s1359-6454(03)00104-6

Wang S, Zhang C, Li X, Huang H, Wang J (2020) First-principle investigation on the interfacial structure evolution of the δ’/θ’/δ’ composite precipitates in Al–Cu–Li alloys. J Mater Sci Technol 58:205–214. https://doi.org/10.1016/j.jmst.2020.03.065

Terrones LAH, Monteiro SN (2007) Composite precipitates in a commercial Al–Li–Cu–Mg–Zr alloy. Mater Charact 58:156–161. https://doi.org/10.1016/j.matchar.2006.04.008

Zheng YH, Liu YX, Wilson N et al (2020) Solute segregation induced sandwich structure in Al–Cu(–Au) alloys. Acta Mater 184:17–29. https://doi.org/10.1016/j.actamat.2019.11.011

Bourgeois L, Zhang Y, Zhang Z, Chen Y, Medhekar NV (2020) Transforming solid-state precipitates via excess vacancies. Nat Commum 11(1):1248. https://doi.org/10.1038/s41467-020-15087-1

Bourgeois L, Dwyer C, Weyland M, Nie J-F, Muddle BC (2011) Structure and energetics of the coherent interface between the θ′ precipitate phase and aluminium in Al–Cu. Acta Mater 59:7043–7050. https://doi.org/10.1016/j.actamat.2011.07.059

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond Ser A Contain Pap Math Phys Character 221:163–198. https://doi.org/10.1098/rsta.1921.0006

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54:11169–11186. https://doi.org/10.1103/PhysRevB.54.11169

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77:3865–3868. https://doi.org/10.1103/PhysRevLett.77.3865

Monkhorst HJ, Pack JD (1976) Special points for Brillouin-zone integrations. Phys Rev B 13:5188–5192. https://doi.org/10.1103/PhysRevB.13.5188

Vaithyanathan V, Wolverton C, Chen LQ (2004) Multiscale modeling of θ′ precipitation in Al–Cu binary alloys. Acta Mater 52:2973–2987. https://doi.org/10.1016/j.actamat.2004.03.001

Wang Y, Liu ZK, Chen LQ, Wolverton C (2007) First-principles calculations of β″-Mg5Si6/α-Al interfaces. Acta Mater 55:5934–5947. https://doi.org/10.1016/j.actamat.2007.06.045

Butler KT, Gautam GS, Canepa P (2019) Designing interfaces in energy materials applications with first-principles calculations. NPJ Comput Mater 5:19. https://doi.org/10.1038/s41524-019-0160-9

Spowage AC, Bray S (2010) Characterization of nanoprecipitation mechanisms during isochronal aging of a pseudo-binary Al-8.7 at. pct Li alloy. Metall Mater Trans A 42:227–230. https://doi.org/10.1007/s11661-010-0498-6

Neibecker P, Leitner M, Kushaim M, Boll T, Anjum D, Ta A-K, Haider F (2017) L12 ordering and δ′ precipitation in Al–Cu–Li. Sci Rep 7:3254. https://doi.org/10.1038/s41598-017-03203-z

Okuda H, Tanaka I, Osamura K, Osawa M, Amemiya Y (1997) Simultaneous SAS and 100 experiments on phase decomposition and reversion in Al–Li binary alloys. J AppI Cryst 30:586–591. https://doi.org/10.1107/S0021889897002409

Yoshimura R, Konno TJ, Abe E, Hiraga K (2003) Transmission electron microscopy study of the evolution of precipitates in aged Al–Li–Cu alloys: the θ′ and T1 phases. Acta Mater 51:4251–4266. https://doi.org/10.1016/s1359-6454(03)00253-2

Biswas A, Siegel DJ, Wolverton C, Seidman DN (2011) Precipitates in Al–Cu alloys revisited: atom-probe tomographic experiments and first-principles calculations of compositional evolution and interfacial segregation. Acta Mater 59:6187–6204. https://doi.org/10.1016/j.actamat.2011.06.036

Hui J, Wang L, Wang B (2020) Theoretical study of the effects of alloying elements on Cu nanotwins. Sci China Phys Mech Astron 63:104612. https://doi.org/10.1007/s11433-020-1543-8

Zhao DD, Li YJ (2018) Carbon segregation at Σ3{1 1 2} grain boundaries in silicon. Comput Mater Sci 143:80–86. https://doi.org/10.1016/j.commatsci.2017.11.001

Tian JZ, Zhao YH, Hou H, Han PD (2017) First-principles investigation of the structural, mechanical and thermodynamic properties of Al2Cu phase under various pressure and temperature conditions. Solid State Commun 268:44–50. https://doi.org/10.1016/j.ssc.2017.09.016

Wang Y, Meng Y, Wang J, Zhang C, Huang H (2020) Mechanical properties of defective L12–Al3X (X = Sc, Lu) phase: a first-principles study. J Rare Earths 39:217–224. https://doi.org/10.1016/j.jre.2020.04.006

Lazar P, Podloucky R (2008) Cleavage fracture of a crystal: density functional theory calculations based on a model which includes structural relaxations. Phys Rev B 78:10414. https://doi.org/10.1103/PhysRevB.78.104114

Janisch R, Ahmed N, Hartmaier A (2010) Ab initio tensile tests of Al bulk crystals and grain boundaries: universality of mechanical behavior. Phys Rev B 81:184108. https://doi.org/10.1103/PhysRevB.81.184108

Zhao DD, Løvvik OM, Marthinsen K, Li YJ (2018) Segregation of Mg, Cu and their effects on the strength of Al Σ5 (210)[001] symmetrical tilt grain boundary. Acta Mater 145:235–246. https://doi.org/10.1016/j.actamat.2017.12.023

Khachaturyan AG, Lindsey TF, Morris JW (1988) Theoretical investigation of the precipitation of δ’ in Al–Li. Metall Mater Trans A 19:249–258. https://doi.org/10.1007/BF02652533

Acknowledgements

The authors would like to thank the helps from all lab mates at the Integrated Computational Materials Engineering (ICME) laboratory, Bei**g Institute of Technology, China. The funding support from the Key Laboratories at Bei**g Institute of Technology (funding#6142902180305, and #61409220124) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: N. Ravishankar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, S., Zhang, C., Li, X. et al. Uncovering the influence of Cu on the thickening and strength of the δ′/θ′/δ′ nano-composite precipitate in Al–Cu–Li alloys. J Mater Sci 56, 10092–10107 (2021). https://doi.org/10.1007/s10853-021-05894-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05894-2