Abstract

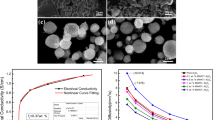

Carbon nanotubes (CNTs)-reinforced Al2O3-matrix nanocomposites were fabricated by a serious of physical dispersion methods and subsequent spark plasma sintering. Crystalline structure, density, mechanical properties and electrical conductivity of the composites were evaluated, and the strengthening and toughening mechanisms were discussed. The results show that there exist angular drifts of the X-ray diffraction peaks for the Al2O3 matrix, which indicates the presence of residual compressive stress in the matrix. The bending strength increased initially with the increase of CNTs content, and reached the maximum with 1.0 wt% CNTs content. The fracture toughness of the nanocomposites also increased with the addition of CNTs, and the composite with 0.5 wt% CNTs has the maximum. The resistivity of composites decreased significantly with the increase in CNTs content, decreasing by seven orders of magnitude when the CNTs content is 2.0 wt%. According to the observations of crack propagation path and fractographs, four toughening mechanisms are summarized: CNTs pull-out, grain interface bridging, crack deflection and crack bridging.

Similar content being viewed by others

References

Puchy V, Hvizdos P, Dusza J, Kovac F, Inam F, Reece MJ (2013) Wear resistance of Al2O3–CNT ceramic nanocomposites at room and high temperatures. Ceram Int 39:5821–5826

Kumari L, Zhang T, Du G, Li W, Wang Q, Datye A, Wu K (2008) Thermal properties of CNT-Alumina nanocomposites. Compos Sci Technol 68:2178–2183

Inam F, Yan H, Peijs T, Reece MJ (2010) The sintering and grain growth behaviour of ceramic–carbon nanotube nanocomposites. Compos Sci Technol 70:947–952

Inam F, Peijs T, Reece MJ (2011) The production of advanced fine-grained alumina by carbon nanotube addition. J Eur Ceram Soc 31:2853–2859

Kumari L, Zhang T, Du GH, Li WZ, Wang QW, Datye A, Wu KH (2009) Synthesis, microstructure and electrical conductivity of carbon nanotube–alumina nanocomposites. Ceram Int 35:1775–1781

Bocanegra-Bernal MH, Dominguez-Rios C, Echeberria J, Reyes-Rojas A, Garcia-Reyes A, Aguilar-Elguezabal A (2016) Spark plasma sintering of multi-, single/double- and single-walled carbon nanotube-reinforced alumina composites: is it justifiable the effort to reinforce them? Ceram Int 42:2054–2062

Duszová A, Dusza J, Tomášek K, Blugan G, Kuebler J (2008) Microstructure and properties of carbon nanotube/zirconia composite. J Eur Ceram Soc 28:1023–1027

Siegel RW, Chang SK, Ash BJ, Stone J, Ajayan PM, Doremus RW, Schadler LS (2001) Mechanical behavior of polymer and ceramic matrix nanocomposites. Scripta Mater 44:2061–2064

Keiichi S, Miho A, Takamichi M, Yamamoto G, Hashida T (2019) Stack-coating of multishell carbon layers templated with carbon nanotubes. Mater Today Commun 21:100608

Peigney A, Laurent C, Dumortier O, Rousset A (1998) Carbon nanotubes–Fe–alumina nanocomposites. Part I: influence of the Fe content on the synthesis of powders. J Eur Ceram Soc 18:1995–2004

Padture NP, Curtin WA (2008) Comment on “Effect of sintering temperature on a single-wall carbon nanotube-toughened alumina-based composite”. Scripta Mater 58:989–990

Zhan G, Kuntz JD, Wan J, Mukherjee AK (2003) Single-wall carbon nanotubes as attractive toughening agents in alumina-based nanocomposites. Nat Mater 2:38–42

Kim SW, Chung WS, Sohn K, Son C, Lee S (2009) Improvement of flexure strength and fracture toughness in alumina matrix composites reinforced with carbon nanotubes. Mater Sci Eng, A 517:293–299

Yamamoto G, Shirasu K, Nozaka Y, Wang W, Hashida T (2014) Microstructure–property relationships in pressureless-sintered carbon nanotube/alumina composites. Mater Sci Eng, A 617:179–186

Jiang D, Thomson K, Kuntz J, Ager J, Mukherjee A (2007) Effect of sintering temperature on a single-wall carbon nanotube-toughened alumina-based nanocomposite. Scripta Mater 56:959–962

Yi J, Xue W, **e Z, Chen J, Zhu L (2015) A novel processing route to develop alumina matrix nanocompositesreinforced with multi-walled carbon nanotubes. Mater Res Bull 64:323–326

Yamamoto G, Omori M, Hashida T, Kimura H (2008) A novel structure for carbon nanotube reinforced alumina composites with improved mechanical properties. Nanotechnology 19:315708

Castillo-Rodríguez M, Muñoz A, Domínguez-Rodríguez A (2018) Creep study on alumina and alumina/SWCNT nanocomposites. J Eur Ceram Soc 38:5497–5502

Kasperski A, Weibel A, Estournès C, Laurent C, Peigney A (2014) Multi-walledcarbon nanotube–Al2O3 composites: covalent or non-covalent functional-ization for mechanical reinforcement. Scripta Mater 75:46–49

Yamamoto G, Suk JW, An J, Piner RD, Hashida T, Takagi T, Ruoff RS (2010) The influence of nanoscale defects on the fracture of multi-walled carbon nanotubes under tensile loading. Diam Relat Mater 19:748–751

Hanzel O, Sedláček J, Šajgalík P (2014) New approach for distribution of carbon nanotubes in alumina matrix. J Eur Ceram Soc 34:1845–1851

Liu Y, Ramirez C, Zhang L, Wu W, Padture NP (2017) In situ direct observation of toughening in isotropic nanocomposites of alumina ceramic and multiwall carbon nanotubes. Acta Mater 127:203–210

Chen M, Fan G, Tan Z, Yuan C, **ong D, Guo Q, Su Y, Naito M, Li Z (2019) Tailoring and characterization of carbon nanotube dispersity in CNT/6061Al composites. Mater Sci Eng, A 757:172–181

Najimi AA, Shahverdi HR (2017) Effect of milling methods on microstructures and mechanical properties of Al6061-CNT composite fabricated by spark plasma sintering. Mater Sci Eng, A 702:87–95

Castillo-Rodríguez M, Muñoz A, Domínguez-Rodríguez A (2016) Comparative study on high temperature mechanical behavior in 3YTZP containing SWCNTs or MWCNTs. J Eur Ceram Soc 36:2573–2578

Bengisu M (2001) Engineering ceramics. Springer, Berlin

ASTM E399 (1991) Annual book of ASTM standards: standard test method for plain strain fracture toughness of metallic materials. ASTM, Philadelphia

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) A critical evaluation of indentation techniques for measuring fracture toughness: I. Direct crack measurement. J Am Ceram Soc 64:533–538

Maniwa Y, Fujiwara R, Kira H, Tou H (2001) Thermal expansion of single-walled carbon nanotube (SWNT) bundles: x-ray diffraction studies. Phys Rev B 64:1402–1404

Jiang K, Wang J, Jian S, Li B (2009) Thermal expansion in single-walled carbon nanotubes and graphene: nonequilibrium green’s function approach. Phys Rev B 80:205429

Kwon YK, Berber S, David T (2004) Thermal contraction of carbon fullerenes and nanotubes. Phys Rev Lett 92:015901

Shirasu K, Yamamoto G, Tamaki I, Ogasawara T, Shimamura Y, Inoue Y, Hashida T (2015) Negative axial thermal expansion coefficient of carbon nanotubes: experimental determination based on measurements of coefficient of thermal expansion for aligned carbon nanotube reinforced epoxy composites. Carbon 95:904–909

Poyato R, Gallardo-López A, Gutiérrez-Mora F, Morales-Rodríguez A, Muñoz A, Domínguez-Rodríguez A (2014) Effect of high SWNT content on the room temperature mechanical properties of fully dense 3YTZP/SWNT composites. J Eur Ceram Soc 34:1571–1579

Wei F, Wei T, Fan Z, Luo G (2008) A new structure for multi-walled carbon nanotubes reinforced alumina nanocomposite with high strength and toughness. Mater Lett 62:641–644

Ahmad K, Pan W (2015) Microstructure-toughening relation in alumina based multiwall carbon nanotube ceramic composites. J Eur Ceram Soc 35:663–671

Miyahara N, Yamaishi K, Mutoh Y, Uematsu K, Inoue M (1994) Effect of grain-size on strength and fracture-toughness in alumina. JSME Int J, Ser A 37:231–237

Seidel J, Claussen N, Rodela J (1995) Reliability of alumina ceramics-effect of grain-size. J Eur Ceram Soc 15:395–404

Zimmermann A, Hoffman M, Flinn BD, Bordia RK, Chuang TJ, Fuller ER, Rodel J (1998) Fracture of alumina with controlled pores. J Am Ceram Soc 81:2449–2457

Shirasu K, Yamamoto G, Hashida T (2019) How do the mechanical properties of carbon nanotubes increase? An experimental evaluation and modeling of the engineering tensile strength of individual carbon nanotubes. Mater Res Express 6:055047

Ahmad I, Cao H, Chen H, Zhao H, Kennedy A, Zhu YQ (2010) Carbon nanotube toughened aluminium oxide nanocomposite. J Eur Ceram Soc 30:865–873

Sarkar S, Das PK (2015) Indentation fracture resistance vs conventional fracture toughness of carbon nanotube/alumina nanocomposites. Metall Mater Trans A 46:5072–5079

**a ZH, Riester L, Curtin WA, Li H, Sheldon BW, Liang J, Chang B, Xu JM (2004) Direct observation of toughening mechanisms in carbon nanotube ceramic matrix composites. Acta Mater 52:931–944

Fan J, Zhuang D, Zhao D, Zhang G, Wu M, Wei F, Fan Z (2006) Toughening and reinforcing alumina matrix composite with single-wall carbon nanotubes. Appl Phys Lett 89:121910

Yamamoto G, Shirasu K, Hashida T, Takagi T, Suk JW, An J, Piner RD, Ruoff RS (2011) Nanotube fracture during the failure of carbon nanotube/alumina composites. Carbon 49:3709–3716

Nozaka Y, Wang W, Shirasu K, Yamamoto G, Hashida T (2014) Inclined slit-based pullout method for determining interfacial strength of multi-walled carbon nanotube–alumina composites. Carbon 78:439–445

Acknowledgements

Thanks are given to the financial supports of the National Natural Science Foundation of China (No. 51601148) and the Aviation Science Foundation of China (No. 2016ZE53046).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, C., Luo, X., Shah, W.A. et al. Mechanical and electrical properties of carbon nanotube-reinforced Al2O3 nanocomposites. J Mater Sci 55, 8728–8740 (2020). https://doi.org/10.1007/s10853-019-04173-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04173-5