Abstract

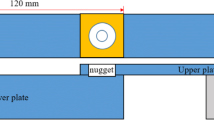

Joint quality of conventional refill friction stir spot welding (RFSSW) is sensitive to welding parameters, and the welding parameters are difficult to control. Thus, deep surface indentation, large hook angle, and void usually occur within the RFSSW joint. An extra-filling RFSSW method is proposed in accordance with defect characteristic. The additional filling method, which was implemented through feed by sidewall, aims to compensate for the material loss within the RFSSW joint. The effect of the filling material on the formation characteristics, triangle void, and mechanical properties of the joint is investigated. Results show that the filling material was stacked in the top region of the stir zone (SZ). Furthermore, the surface indentation of the welding spot, hook angle, and bonding ligament thickness of extra-filling RFSSW joint were reduced, and triangle void at the bottom of the sleeve-affected zone was eliminated. Thus, tensile-shear load of extra-filling RFSSW joint was higher than that of conventional RFSSW joint. This study reveals the filling mechanism of triangle void and fracture behavior of RFSSW joints simultaneously. The squeezing effect of filling material makes more material in the SZ and the lap interface outside the SZ fill the triangle void. The filling of triangle void increases joint net-section area and decreases the stress concentration, and the samples fracture along the bonding ligament.

Similar content being viewed by others

References

Iwashita T (2003) Method and apparatus for joining. United States patent US 6601751 B2

Tier MD, Rosendo TS, Santos JFD, Huber N, Mazzaferro JA, Mazzaferro CP, Strohaecker TR (2013) The influence of refill FSSW parameters on the microstructure and shear strength of 5042 aluminium weld. J Mater Process Technol 213:997–1005

Shen ZK, Yang XQ, Zhang ZH, Cui L, Li TL (2013) Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater Des 44:476–486

Tier MD, dos Santos JF, Olea CW et al (2008) The influence of weld microstructure on mechanical properties of Alclad AA2024-T3. Friction Spot Welded. SAE Technical Paper

Mazzaferro JAE, Rosendo TS, Mazzaferro CCP, Ramos FD, Tier MAD, Strohaecker TR, dos Santos JF (2009) Preliminary study on the mechanical behavior of friction spot welds. Soldagem Insp 14:238–247

Nasiri AM, Shen ZK, Shao J, Hou C, Gerlich AP (2017) Failure analysis of tool used in refill friction stir spot welding of Al 2099 alloy. Eng Fail Anal 84:25–33. https://doi.org/10.1016/j.engfailanal.2017.09.009

Boldsaikhan E, Fukada S, Fujimoto M, Kamimuki K, Okada H, Duncan B, Bui P, Yeshiambel M, Brown B, Handyside A (2017) Refill friction stir spot joining for aerospace aluminum alloys. In: Friction stir welding and processing IX, pp 237–246

Safarkhanian MA, Goodarzi M, Boutorabi SMA (2009) Effect of abnormal grain growth on tensile strength of Al–Cu–Mg alloy friction stir welded joints. J Mater Sci 44:5452–5458. https://doi.org/10.1007/s10853-009-3735-x

da Silva AAM, dos Santos JF, Rosendo TR, Fabiano DR (2007) Performance evaluation of 2-mm thick Alclad AA2024 T3 aluminium alloy friction spot welding. SAE Technical Paper

de Castro CC, Plaine AH, de Alcântara NG, dos Santos JF (2018) Taguchi approach for the optimization of refill friction stir spot welding parameters for AA2198-T8 aluminum alloy. Int J Adv Manuf Technol 99:1927–1936

Pieta G, dos Santos J, Strohaecker TR, Clarke T (2014) Optimization of friction spot welding process parameters for AA2198-T8 sheets. Mater Manuf Process 29:934–940

Yang XW, Fu T, Li WY (2014) Friction stir spot welding: a review on joint macro- and micro-structure, property, and process modelling. Adv Mater Sci Eng 2014:1–11

Xu ZW, Li ZW, Ji SD, Zhang LG (2018) Refill friction stir spot welding of 5083-O aluminum alloy. J Mater Sci Technol 34:878–885

Li ZW, Xu ZW, Zhang LG, Yan ZJ (2017) Friction spot welding of dissimilar 6063/5083 aluminium alloys. Mater Sci Technol 33:1626–1634

Oliveira PHF, Amancio-Filho ST, Santos JFD, Hage E Jr (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64:2098–2101

Zhao YQ, Liu HJ, Chen SX, Lin Z, Hou JC (2014) Effects of sleeve plunge depth on microstructures and mechanical properties of friction spot welded alclad 7B04-T74 aluminum alloy. Mater Des 62:40–46

Zhou L, Luo LY, Zhang TP, He WX, Huang YX, Feng JC (2017) Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy. Int J Adv Manuf Technol 92:3425–3433

Yue YM, Shi Y, Ji SD, Zhang LG, Wang Y (2017) Effect of Sleeve Plunge depth on microstructure and mechanical properties of refill friction stir spot welding of 2198 aluminum alloy. J Mater Eng Perform. https://doi.org/10.1007/s11665-017-2929-7

Shi Y, Yue YM, Zhang LG, Wang Y (2017) Refill friction stir spot welding of 2198-T8 aluminum alloy. Trans Indian Inst Met 71:139–145. https://doi.org/10.1007/s12666-017-1146-2

Ibrahim HK, Khuder AWH, Muhammed MAS (2017) Effects of rotational speeds and tool pin geometry on microstructure and mechanical properties of refilled friction stir spot welds of similar AA2024-T3 aluminum alloy sheets. Int J Eng Res Technol 6(4):937–952

Heimendahl MV (1967) Precipitation in aluminum-gold. Acta Met 15(9):1441–1452

Rosendo T, Parra B, Tier MAD, da Silvae AAM, dos Santos JF, Strohaecker TR, Alcântara NG (2011) Mechanical and microstructural investigation of friction spot welded AA6181-T4 aluminium alloy. Mater Des 32:1094–1100

Parra B, Saccon VT, Alcântara NGD, Rosendo T, Santos JF (2011) An investigation on friction spot welding in AA6181-T4 alloy. Tecnologia Em Metalurgia Materiais E Mineraã§ã£o 8:184–190

Shen ZK, Yang XQ, Yang S, Zhang ZH, Yin YH (2014) Microstructure and mechanical properties of friction spot welded 6061-T4 aluminum alloy. Mater Des 54:766–778

Ji SD, Wang YX, Zhang J, Li ZW (2016) Influence of rotating speed on microstructure and peel strength of friction spot welded 2024-T4 aluminum alloy. Int J Adv Manuf Technol 90:717–723

Li ZW, Ji SD, Ma YN, Chai P, Yue YM, Gao SS (2016) Fracture mechanism of refill friction stir spot-welded 2024-T4 aluminum alloy. Int J Adv Manuf Technol 86:1925–1932

Li ZW, Gao SS, Ji SD, Yue YM, Chai P (2016) Effect of rotational speed on microstructure and mechanical properties of refill friction stir spot welded 2024 Al alloy. J Mater Eng Perform 25(4):1673–1682

Cao JY, Wang M, Kong L, Yin YH, Guo LJ (2017) Numerical modeling and experimental investigation of material flow in friction spot welding of Al 6061-T6. Int J Adv Manuf Technol 89:2129–2139

Cao JY, Wang M, Kong L, Zhao HX, Chai P (2017) Microstructure, texture and mechanical properties during refill friction stir spot welding of 6061-T6 alloy. Mater Charact 128:54–62

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Chai, P., Ma, H. et al. Formation mechanism and fracture behavior in extra-filling refill friction stir spot weld for Al–Cu–Mg aluminum alloy. J Mater Sci 55, 358–374 (2020). https://doi.org/10.1007/s10853-019-03940-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03940-8