Abstract

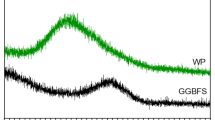

Ground granulated blast furnace slag (ggbf slag) and metakaolin were blended and the combination was activated by sodium hydroxide solution. Two mix series were investigated, one with low NaOH concentration (9–16 wt%) and the other with a high NaOH concentration of 25 wt%. The reaction progress of the alkali-activated pastes was indirectly measured by isothermal calorimetry as well as by ultrasonic measurements. Both methods show an acceleration of the condensation reaction of the alkali-activated blends compared to both single phases. The acceleration effect is more considerable at the higher activator concentration related to a higher reaction degree of the metakaolin.

Similar content being viewed by others

References

Davidovits J (1976) In: IUPAC international symposium on macromolecules. Topic III, New polymers of high stability, Stockholm

Davidovits J (1999) In: Davidovits J (ed) Proceedings of the second international conference geopolymere ’99, St. Quentin, France, p 9

Kühl H (1908) US Patent 900939

Purdon AO (1940) J Soc Chem Ind 59(9):191

Schilling PJ, Butler LG, Roy A, Eaton HC (1994) J Am Ceram Soc 77(9):2363

Wang S-D, Scrivener KL (2003) Cem Concr Res 33:769

Richardson IG, Brough AR, Brydson R, Groves GW, Dobson CM (1993) J Am Ceram Soc 76(9):2285

Scrivener KL, Wang S-D (1995) Cem Concr Res 25(3):561

Granizo ML, Alonso S, Blanco-Varela MT, Palomo A (2002) J Am Ceram Soc 85(1):225

Palomo A, Blanco-Varela T, Alonso S, Granizo L (2003) In: Proceedings of the 11th congress on the chemistry of cement (ICCC), Durban, South Africa, p 425

Yip CK, van Deventer JSJ (2003) J Mater Sci 38:3851. doi:10.1023/A:1025904905176

Yip CK, Lukey GC, van Deventer JSJ (2005) Cem Concr Res 35:1688

Buchwald A, Hilbig H, Kaps C (2007) J Mater Sci 42(9):3024. doi:10.1007/s10853-006-0525-6

Hilbig H, Buchwald A (2006) J Mater Sci 41(19):6488. doi:10.1007/s10853-006-0755-7

Alonso S, Palomo A (2001) Cem Concr Res 31(1):25

Granizo ML, Blanco MT (1998) J Therm Anal 52:957

Fernandez-Jimenez A, Puertas F, Artega A (1998) J Therm Anal 52:945

Gruskovnjak A, Lothenbach B, Holzer L, Figi R, Winnefeld F (2006) Adv Cem Res 18(3):119

Tatarin R, Erfurt W, Stark J (2004) ZKG Int 57(8):69

Grosse CU, Reinhardt H-W, Krüger M, Beutel R (2006) In: Reinhardt H-W (ed) Proceedings of the advanced testing of fresh cementitious materials, Stuttgart, p 83

Lawson JL (2008) Diploma thesis for the degree of Master of Science in Mechanical Engineering, Rochester Institute of Technology, Rochester, NY. https://ritdml.rit.edu/dspace/bitstream/1850/7356/1/JLawsonThesis09-2008.pdf. Accessed 27 July 2009

Lawson J, Varela B, Panandiker RSP, Helguera M (2008) In: Lin H-T, Koumoto K, Kriven WM (eds) Developments in strategic materials: ceramic engineering and science proceedings, vol 29, issue 10, p 143. ISBN: 978-0-0470-34500-9

Granizo ML, Blanco-Varela MT, Palomo A (2000) J Mater Sci 35:6309. doi:10.1023/A:1026790924882

Shi C, Krivenko P, Roy D (2006) Alkali-activated cements and concretes. Taylor and Francis, London, p 376. ISBN: 0-4157-0004-3

Sayers CM, Dahlin A (1993) Adv Cem Based Mater 1:12

Robeyst N, Gruyaert E, Grosse CU, Belie ND (2008) Cem Concr Res 38:1169

Herb A (2003) Indirekte Beobachtungen des Erstarrens und Erhärtens von Zementleim, Mörtel und Beton mittels Schallwellenausbreitung. Universität Stuttgart, Stuttgart

Fernandez-Jimenez A, Puertas F (1997) Cem Concr Res 27(3):359

Wassing W, Tigges VE (2008) Cem Int 6(5):62

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buchwald, A., Tatarin, R. & Stephan, D. Reaction progress of alkaline-activated metakaolin-ground granulated blast furnace slag blends. J Mater Sci 44, 5609–5617 (2009). https://doi.org/10.1007/s10853-009-3790-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3790-3