Abstract

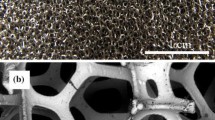

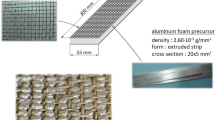

Sandwich structures are considered as viable engineering constructions due to their unique structural, physical, and mechanical properties. An investigation of the mechanical characteristics of sandwich structures suitable for high temperature application is presented. A process has developed to produce high temperature sandwich structures by depositing alloy 625 skins on Ni alloy foam cores using air plasma spraying (APS). The experimental investigation consisted of fabrication of sandwich structures and testing of mechanical performance of sandwich specimens under flexural loading conditions. The responses of the as-fabricated sandwich structure to heat treatment were investigated. The strength of the sandwich structure was significantly increased after heat treatment. The influence of skin thickness on mechanical behavior of sandwich structures was examined by performing four-point bending test on sandwich samples with skin thicknesses of 0.5 and 0.1 mm. The larger the skin thickness, the higher the strength of the sandwich beams. Comparison between the results of four-point bending tests on sandwich structures with different skin thicknesses will help us to understand the effect of skin thickness on the failure mechanism of sandwich structures.

Similar content being viewed by others

References

Vinson JR (1999) The behavior of sandwich structures of isotropic and composite materials. Technomic Publishing Company, Lancaster

Wahll MJ (1979) Handbook of superalloys. International Alloy Compositions and Designations Series, Battelle Press, Columbus

Swellam M, Yi S, Fouad Ahmad M, Huber LM (1997) J Appl Polym Sci 63:383

Banhart J (2001) Prog Mater Sci 46:559

Evans AG, Hutchinson JW, Fleck NA, Ashby MF, Wadley HNG (2001) Prog Mater Sci 46:309

Singleton MF, Murray JL, Nash P (1991) Phase diagrams of binary nickel alloys. ASM International, Materials Park, OH

Azarmi F (2005) Adv Mater Processes 163(8):37

Heimann RB (1996) Plasma spray coating—principles and application. VCH Publishing, New York

Fauchais P (2004) J Phys D Appl Phys 37:086

Salimi Jazi HR, Coyle TW, Mostaghimi J (2007) Metall Mater Trans A 38:476

Caprino G, Teti R (1989) Sandwich structures: handbook. II Prato, Padua

Ashby MF (2005) Materials selection in mechanical design, 3rd edn. Butterworth-Heinemann, Oxford

Daniel IM, Gdoutos EE, Abot JL, An-Wang K (2003) J Thermoplast Compos Mater 16(4):345

Cantwell WJ, Davies P (1996) Appl Compos Mater 3:407

Cantwell WJ, Scudamore R, Ratcliff J, Davies P (1999) Compos Sci Technol 59:2079

McCormack TM, Miller R, Kesler O, Gibson LJ (2001) Int J Solids Struct 38:4901

Thomsen OT, Bozhevolnaya E, Lyckegaard A (2005) In: Advancing with sandwich structures and materials. Proceedings of the 7th International Conference on Sandwich Structures, Aalborg University, Aalborg, Denmark, p 29

ASTM International (2000) Standard test method for flexural properties of sandwich constructions. Designation: C 393-00, Annual Book of ASTM Standards, v 03.01

Belingardi G, Cavatorta MP, Duella R (2003) Compos Struct 61:13

Mohan K, Hon YT, Idapalapati S, Seow HP (2005) Mater Sci Eng A 409:292

Allen H (1969) Analysis and design of structural sandwich panels. Oxford Pergamon Press, New York

Azarmi F, Coyle TW, Mostaghimi J (2008) J Therm Spray Technol 17(1):144

Azarmi F, Coyle TW, Mostaghimi J (2009) Surf Coat Technol 203:1045

Draft International Standard ISO/DIS 14704 (2007) Fine ceramics (advanced ceramics, advanced technical ceramics)—test method for flexural strength of monolithic ceramics at room temperature. International Organization for Standardization

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azarmi, F., Coyle, T.W. & Mostaghimi, J. Flexural properties of sandwich beams consisting of air plasma sprayed alloy 625 and nickel alloy foam. J Mater Sci 44, 2836–2843 (2009). https://doi.org/10.1007/s10853-009-3375-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3375-1