Abstract

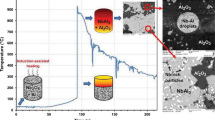

The aim of the present paper is to review the recent progress in the synthesis of in situ particle reinforced aluminum composites using thermal, mechanical and combined mechanical-thermal activation of aluminothermic reduction reactions. The combination of combustion synthesis (CS) and mechanosynthesis (MS) is the most recent development in the processing of advanced materials like micro and nano aluminum based composites. The combined mechanical thermal synthesis (MTS) has widened the possibilities for both CS and MS. MTS holds great potential for commercial viability and offers exciting processing route for the synthesis of advanced materials. Enhanced reaction kinetics and extended concentration limits in MTS are demonstrated by illustrating the synthesis of aluminum based nanocomposite involving Al–CeO2.

Similar content being viewed by others

References

Tjong SC, Ma ZY (2000) Mater Sci Eng 29:49

Girot FA, Quenisset JM, Naslain R (1987) Compos Sci Technol 30:155

Torralba JM, da Costa CE, Velasco F (2003) J Mater Process Technol 133:203

Daniel BSS, Murthy VSR, Murty GS (1997) J Mater Process Technol 68:132

Suryanarayana C (2001) Prog Mater Sci 46:1

Thostenson ET, Li C, Chou T-W (2005) Compos Sci Technol 65:491

Gale WF, Tottemeier TC (eds) (2003) Smithells metals reference book, 8th edn. Elseiver, Butterworth, USA

Moore JJ, Feng HJ (1995) Prog Mater Sci 39:243

Moore JJ, Feng HJ (1995) Prog Mater Sci 39:275

Merzhanov G (1995) Ceram Int 21:371

Patil KC, Aruna ST, Mimani T (2002) Curr Opin Solid State Mater Sci 6:507

Zhu P, Li JCM, Liu CT (2003) Mater Sci Eng A 357:248

Gotman I, Koczak MJ, Shtessel E (1994) Mater Sci Eng A 187:189

Wang D, Shi Z (2004) J Adv Mater 36:56

Peng HX, Wang DZ, Geng L, Yao CK (1997) Scripta Mater 37(2):199

Huang Z-J, Yang B, Cui H, Zhang J-S (2003) Mater Sci Eng A 351:15

Zhang DL (2004) Prog Mater Sci 49:537

Matteazzi P, Le Caer G (1992) J Am Ceram Soc 75:2749

Shingu PH, Ishihara KN (1995) JIM 36:96

Prabhu B, Suryanarayana C, An L, Vaidyanathan R (2006) Mater Sci Eng A 425:192

Murthy BS, Ranganathan S (1998) Int Mater Rev 43:101

Takacs L (2002) Prog Mater Sci 47:355

(Sam) Froes FH, Trindade B (2004) J Mater Sci 39:5019

Cocco G, Mulas G, Schiffini L (1995) JIM 36:150

McCormick PG (1995) JIM 36:161

Nagumo M (1995) JIM 36:170

Schaffer GB, McCormick PG (1989) Scripta Metall 23:835

Schaffer GB, McCormick PG (1990) Metall Trans 21A:2789

Botta FWJ, Tomasi R, Pallone EMJA, Yavari AR (2001) Scripta Mater 44:1735

Lu L, Zhang YF (1999) J Alloys Compd 290:279

Das D, Samntha A, Chattopadhyay PP (2006) Development of bulk nano-Al2O3 dispersed Cu-matrix composite using ball milled precursor. ICAMMP, IIT-Kharagpur, India

Jain M et al (2004) Synthesis of Fe-Al2O3 nanocomposite through reactive milling. ISAMAP, IIT-Kharagpur, India

Venugopal T, Prasad Rao K, Murty BS (2005) Mater Sci Eng A 393:382

Takacs L (1992) Mater Lett I3:119

Takacs L (1993) Nanostructured Mater 2:241

Ivanov E, Suryanarayana C (2000) J Mater Synth Process 8:235

Grigorieva TF, Barinova AP, Lyakhov NZ (2003) J Nanoparticle Res 5:439

Wu JM, Li ZZ (2000) J Alloys Compd 299:9

** S, Qu X, Ma M, Zhou J, Zheng X, Wang X (1998) J Alloys Compd 268:211

Grigorieva TF, Korchagin M, Lyakhov NZ (2002) KONA 20:144

Osso D, Tillement O, Mocellin A, Le Caer G, Babushkin O, Lindback T (1995) J Eur Ceram Soc 15:1207

Shaw LL (2001) Mater Manufact Process 16:405

Li J, Li F, Hu K (2004) J Mater Process Technol 147:236

Reddy BSB, Das K, Pabi SK, Das S (2007) Mater Sci Eng A 445–446:341

Reddy BSB, Karabi Das, Pabi SK, Das Siddhartha (in press) Preparation of Al–Ce/Al2O3 nanocomposite powder by high-energy ball milling and subsequent heat treatment, PMAI-2006, Hyderabad, India

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reddy, B.S.B., Das, K. & Das, S. A review on the synthesis of in situ aluminum based composites by thermal, mechanical and mechanical–thermal activation of chemical reactions. J Mater Sci 42, 9366–9378 (2007). https://doi.org/10.1007/s10853-007-1827-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1827-z