Abstract

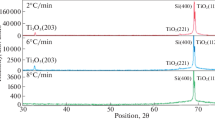

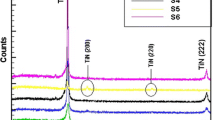

Titanium films of different thickness at different substrate temperatures are prepared using PVD method. The nanostructure of these films was obtained using X-ray diffraction (XRD) and AFM, while the thicknesses were measured by means of Rutherford back scattering (RBS) technique. Resistivity, Hall coefficient, concentration of carriers and the mobility in these films are obtained. The results show that, the rutile phase of TiO2 is formed which is initially amorphous and as the film thickness increases it tends to become textured in (020) direction, which is more pronounced at higher temperatures and possibly transforms to anatase TiO2 with (112) orientation for thickest films of 224 nm. The conductivity and concentration of carriers increase with thickness, while the Hall coefficient and the mobility decrease. The activation energies in these samples were obtained from the Arrhenius plots of σ and R H. For thinner films ( \( E_{\hbox{a}} \approx 0.4 - 0.6 \) eV) and for thickest film (224 nm) a break point is observed at about 500 K, which is consistent with the idea of more processes becoming activated at higher temperatures.

Similar content being viewed by others

References

Holleck H (1986) J Vac Sci Technol A 4:2661

Sundgren J-E, Hentzell HTG (1986) J Vac Sci Technol A 4:2259

Milosev I, Navinsek B, Strehblow H-H (1995) In: Corrosion properties of hard PVD nitride coatings (with emphasis on TiN), Scientific Series of the International Bureau, vol 37. GmbH, Forschungszentrum Julich

Sikkens M, Heereveld AAMTV, Vogelzang E, Boose CA (1983) Thin Solid Films 108:229

Kopacz U, Ried R (1992) Z Metallkd 83:492

Claesson Y, Georgson M, Roos A, Ribbing C-G (1990) Solar Energy Mater 20:55

Long M, Rack HJ (1998) Biomaterials 19:1621–1639

Fox MA, Dulay MT (1993) Chem Rev 93:341

Linsebigler AL, Lu G, Yates JT Jr. (1995) Chem Rev 95:735

Anpo M, Takeuchi M (2003) J Catal. 216:503

Hagfeldt A, Gratzel M (1995) Chem Rev 95:49

Gratzel M (2001) Nature 414:338

Gopel W, Reinhardt G (1996) In: Baltes H, Gopel W, Hesse J (eds) Sensors update. Wiley, New York, p. 47

Skubal LR, Meshkov NK, Vogt MC (2002) J Photochem Photobiol A: Chem 148:103

Chang HT, Wu N-M, Zhu F (2000) Water Res 34:407

Mills A, Hill G, Bhopal S, Parkin IP, O’Neill SA (2003) J Photochem Photobiol A: Chem. 160:185

Savaloni H, Moradi GR, Player MA (2005) Vacuum 77:245

Sathyamoorthy R, Narayandass SK, Mangalaraj D (2003) Solar Energy Mater Solar Cells 76:339

Toney MF, Lee W-Y, Hedstrom JA, Kellock A (2003) J Appl Phys 93:9902

Arranz A, Palacio C (2005) Surf Sci 588(1–3):92

Moon K-S, Shin S-C (1996) J Appl Phys 79(8):4991

Savaloni H, Bagheri Najmi S (2002) Vacuum 66(1):49

Cartier M, Auffret S, Bayle-Guillemaud P, Ernult F, Fettar F, Dienya B (2002) J Appl Phys 91(3):1436

Savaloni H, Shahrestani SA, Player MA (1997) Nanotechnology 8(4):172

Qiu H, Wang F, Wu P, Pan L, Li L, **ong L, Tian Y (2002) Thin Solid Films 414:150

Cai K, Muller M, Bossert J, Rechtenbach A, Jandt KD (2005) Appl Surf Sci 250(1–4):252

Savaloni H, Taherizadeh A, Zendehnam A (2004) Physica B 349:44

Savaloni H, Player MA, Marr GV (1992) Vacuum 43:965

Savaloni H, Player MA (1995) Vacuum 46:167

Huang TC, Lim G, Parmigiani F, Kay E (1985) J Vac Sci Technol A3:2161

Clark RJL (1973) In: Bailar SC, Emelens HJ, Trofman-Dickenson AF (eds) Comprehensive inorganic chemistry, vol 3. Pergamon Press, Oxford, pp 375

Reece M, Morrell R (1991) J Mater Sci 26: 5566

Rickerby DG (1997) Philos Mag B76:573

Barbe CJ, Arendse F, Comte P, Jirousek M, Lenzmann F, Shklover V, Gratzel M (1997) J Am Ceram Soc 80:3157

Negishi N, Takeuchi K, Ibusuki T, Datye AK (1999) J Mater Sci Lett 18: 515

Zeman P, Takabayashi S (2002) Surf Coat Technol 153:93

Lobl P, Huppertz M, Mergel D (1994) Thin Solid Films 251:72

Frenck HJ, Kulisch W, Kuhr M, Kassing R (1991) Thin Solid Films 201:327

Meng LJ, Santos MP (1993) Thin Solid Films 226:22

Okimura K, Shibata A, Maeda N, Tachibana K, Noguchi Y, Tsuchida K (1995) Jpn J Appl Phys 34:4950

Kazunori F, Gikan T, Iso Y (1993) Jpn J of Appl Phys 1:3561

Tokuda K, Miyashita K, Ubukata T, 7th international symposium on sputtering and plasma process (ISSP 2003), pp 96–99

Stamate MD (2000) Thin Solid Films 372:246

Vigil E, Saadoun L, Ayllon JA, Domenech X, Zumeta I, Rodriguez-Clemente R (2000) Thin Solid Films 365:12

Bessergenev VG, Khmelinskii IV, Pereira RJF, Krisuk VV, Turgambaeva AE, Igumenov IK (2002) Vacuum 64:275

Muller J, Singh B, Surpplice NA (1972) J Phys D Appl Phys 5:1177

Curzon AE (1984) J Less Common Metals 98:149

Holloway DM, Swartz WE Jr (1977) Appl Spectrosc 31:167

Movchan BA, Demchishin AV (1963) Phys Met Metall 28:83

Thornton JA (1975) J Vac Sci Technol 12:830

Messier R (1986) J Vac Sci Technol A 4:490

Grovenor CRM, Hentzell HTG, Smith DA (1984) Acta Metall 32:773

Acknowledgements

This work was carried out with the support of the University of Tehran and the Plasma Physics Research Centre, Science and Research Campus of I. A. University. We would like to thank the staff at the Nuclear Physics Research Centre of the Atomic Energy Authority of Iran, for their help with the RBS measurements. We are grateful to Ms. M. Shariati of Plasma Physics Research Centre, for AFM measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Savaloni, H., Khojier, K. & Alaee, M.S. Characteristics of nanostructure and electrical properties of Ti thin films as a function of substrate temperature and film thickness . J Mater Sci 42, 2603–2611 (2007). https://doi.org/10.1007/s10853-006-1340-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1340-9