Abstract

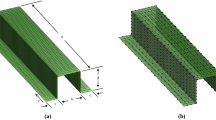

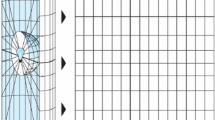

Statistical process control (SPC) methods have been extensively applied to monitor the quality performance of manufacturing processes to quickly detect and correct out-of-control conditions. As sensor and measurement technologies advance, there is a continual need to adapt and refine SPC methods to effectively and efficiently use these new data-sets. One of the most state-of-the-art dimensional measurement technologies currently being implemented in industry is the 3D laser scanner, which rapidly provides millions of data points to represent an entire manufactured part’s surface. Consequently, this data has a great potential to detect unexpected faults, i.e., faults that are not captured by measuring a small number of predefined dimensions. However, in order for this potential to be realized, SPC methods capable of handling these large data-sets need to be developed. This paper presents an approach to performing SPC using point clouds obtained through a 3D laser scanner. The proposed approach transforms high-dimensional point clouds into linear profiles through the use of Q–Q plots, which can be monitored by well established profile monitoring techniques. In this paper point clouds are simulated to determine the performance of the proposed approach under varying fault scenarios. In addition, experimental studies were performed to determine the effectiveness of the proposed approach using actual point cloud data. The results of these experiments show that the proposed approach can significantly improve the monitoring capabilities for manufacturing parts that are characterized by complex surface geometries.

Similar content being viewed by others

References

Choudhary A. K., Harding J. A., Tiwari M. K. (2009) Data mining in manufacturing: A review based on the kind of knowledge. Journal of Intelligent Manufacturing 20(5): 501–521. doi:10.1007/s10845-008-0145-x

Colosimo B. M., Mammarella F., Petro S. (2010) Quality control of manufactured surfaces. In: Lenz H.-J., Wilrich P.-T. (Eds.), Frontiers of statistical quality control, Vol. 9. Springer, Vienna

Feng H.-Y., Liu Y., ** F. (2001) Analysis of digitizing errors of a laser scanning system. Precision Engineering 25: 185–191

Gunter B. (1994) Q–Q plots. Quality Progress 27(2): 81–86

Hisao S.-W., Chuang J. C. (2003) A reverse engineering based approach for product form design. Design Studies 24(2): 155–171

Isheil A., Gonnet J. P., Joannic D., Fontaine J. F. (2011) Systematic error correction of a 3D laser scanning measurement device. Optics and Lasers in Engineering 49(1): 16–24

Jiang W., Han S. W., Tsui K. L., Woodall W. H. (2011) Spatiotemporal surveillance methods in the presence of spatial correlation. Statistics in Medicine 30(5): 569–583. doi:10.1002/sim.3877

Kang L., Albin S. L. (2000) On-line monitoring when the process yields a linear profile. Journal of Quality Technology 32(4): 418–426

Kendall M. G., Stuart A., Ord J. K., Arnold S. F., O’Hagan A. (1994) Kendall’s advanced theory of statistics. Edward Arnold/Halsted Press, London/New York

Kim K., Mahmoud M. A., Woodall W. H. (2003) On the monitoring of linear profiles. Journal of Quality Technology 35(3): 317–328

Lucas J. M., Saccucci M. S. (1990) Exponentially weighted moving average control schemes—Properties and enhancements. Technometrics 32(1): 1–12

Mahmoud M. A., Morgan J. P., Woodall W. H. (2010) The monitoring of simple linear regression profiles with two observations per sample. Journal of Applied Statistics 37(8): 1249–1263

Megahed, F. M., Wells, L. J., Camelio, J. A., & Woodall, W. H. (2012). A spatiotemporal method for the monitoring of image data. Quality and Reliability Engineering International. doi:10.1002/qre.1287.

Megahed F. M., Woodall W. H., Camelio J. A. (2011) A review and perspective on control charting with image data. Journal of Quality Technology 43(2): 83–98

Mohaghegh K., Sadeghi M. H., Abdulla A. (2007) Reverse engineering of turbine blades based on design intent. International Journal of Advanced Manufacturing Technology 32(9–10): 1009–1020

Mohib A., Azab A., Elmaragy H. (2009) Feature-based hybrid inspection planning: A mathematical programming approach. The International Journal of Computer Integrated Manufacturing 22(1): 13–29

Montgomery D. C. (2008) Introduction to statistical quality control. Wiley, Hoboken, NJ

NIST/SEMATECH. (2003). e-Handbook of statistical methods. http://www.itl.nist.gov/div898/handbook/.

Panagiotidou S., Tagaras G. (2010) Statistical processs control and condition-based maintenance: A meaningful relationship through data sharing. Production and Operations Management 19(2): 156–171

Reinhart G., Tekouo W. (2009) Automatic programming of robot-mounted 3D optical scanning devices to easily measure parts in high-variant assembly. CIRP Annals—Manufacturing Technology 58(1): 25–28

Shi, Q., & **, N. (2008). Automated data processing for a rapid 3D surface inspection system. IEEE International Conference on Robotics and Automation, 3939–3944. doi:10.1109/ROBOT.2008.4543816.

Shi Q., ** N., Spagnuluo C. (2007) A feedback design to a CAD-guided area sensor planning system for automated 3D shape inspection. Computer-Aided Design & Applications 4: 209–218

Son S., Park H., Lee K. H. (2002) Automated laser scanning system for reverse engineering and inspection. International Journal of Machine Tools & Manufacture 42(8): 889–897

Sonesson C. (2007) A CUSUM framework for detection of space-time disease clusters using scan statistics. Statistics in Medicine 26: 4770–4789

Tamura S., Kim E.-K., Close R., Sato Y. (1994) Error correction in laser scanner three-dimensional measurement by two-axis model and coarse-fine parameter search. Pattern Recognition 27(3): 331–338

Tsui K.-L., Wong S. Y., Jiang W., Lin C.-J. (2011) Recent research and developments in temporal and spatiotemporal surveillance for public health. IEEE Transactions on Reliability 60(1): 49–58

Várady T., Martin R. R., Cox J. (1997) Reverse engineering of geometric models—An introduction. Computer-Aided Design 29(4): 255–268

Wang K., Tsung F. (2005) Using profile monitoring techniques for a data-rich environment with huge sample size. Quality and Reliability Engineering International 21(7): 677–688

Wang X. Z., McGreavy C. (1998) Automatic classification for mining process operational data. Industrial & Engineering Chemistry Research 37(6): 2215–2222

Wells, L. J., Megahed, F. M., Camelio, J. A., & Woodall, W. H. (2011). A framework for variation visualization and understanding in complex manufacturing systems. Journal of Intelligent Manufacturing. doi:10.1007/s10845-011-0529-1.

Woodall W. H. (2007) Current research on profile monitoring. Produção 17: 420–425

Woodall W. H., Spitzner D. J., Montgomery D. C., Gupta S. (2004) Using control charts to monitor process and product quality profiles. Journal of Quality Technology 36(3): 309–320

Wu S.-K., Hu J., Wu S. M. (1994) A fault identification and classification scheme for an automobile door assembly process. The International Journal of Flexible Manufacturing Systems 6: 261–285

** F., Liu Y., Feng H.-Y. (2001) Error compensation for three-dimensional line laser scanning data. The International Journal of Advanced Manufacturing Technology 18: 211–216

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wells, L.J., Megahed, F.M., Niziolek, C.B. et al. Statistical process monitoring approach for high-density point clouds. J Intell Manuf 24, 1267–1279 (2013). https://doi.org/10.1007/s10845-012-0665-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0665-2