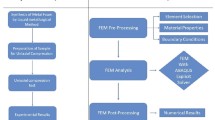

The non-linear behavior of uniform-size cellular foams made of aluminum is investigated when subjected to compressive loads while comparing numerical results obtained in the Finite Element Method software (FEM) ANSYS workbench and ANSYS Mechanical APDL (ANSYS Parametric Design Language). The numerical model is built on AUTODESK INVENTOR, being imported into ANSYS and solved by the Newton–Raphson iterative method. The most similar conditions were used in ANSYS mechanical and ANSYS workbench, as possible. The obtained numerical results and the differences between the two programs are presented and discussed

Similar content being viewed by others

References

E. Andrews, W. Sanders, and L. J. Gibson, “Compressive and tensile behaviour of aluminum foams,” Mater. Sci. Eng., A270, 113–124 (1999).

X. Q. Cao, Z. H. Wang, H. W. Ma, L. M. Zhao, and G. T. Yang, “Effects of cell size on compressive properties of aluminum foam,” Trans. Nonferrous Met. SOC. China, 16, 351–356 (2006).

C. D. Carvalho, Simulação numérica e verificação experimental do comportamento elástoplástico de espumas metálicas [in Portuguese], MSc. Thesis, University of Minho (2012).

H. P. Degischer and B. Kriszt, Handbook of Cellular Metals: Production, Processing, Applications, Wiley-VCH Verlag GmbH & Co. KGaA (2002).

L. J. Gibson and M. F. Ashby, Cellular Solids. Structure and Properties, Cambridge University Press (1997).

T. G. Nieh, K. Higashi, and J. Wadsworth, “Effect of cell morphology on the compressive properties of open-cell aluminum foams,” Mater. Sci. Eng., A283, 105–110 (2000).

J. F. Rakow and A. M. Waas, “Size effects and the shear response of aluminum foam,” Mech. Mater., 37, 69–82 (2005).

H. M. Silva, N. R. Peixinho, and F. S. Silva, “Numerical study on the sensitivity analysis for strength and stiffness of regular cellular solids,” Int. J. Appl. Res. Mech. Eng., 3, No. 1, 93–98 (2013).

L. S. **e and K. C. Chan, “The effect of strut geometry on the yielding behavior of open-cell foams,” Int. J. Mech. Sci., 48, 249–255 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Prikladnaya Mekhanika, Vol. 53, No. 3, pp. 137–144, May–June, 2017.

Rights and permissions

About this article

Cite this article

Silva, H.M., Carvalho, C.D. & Peixinho, N.R. Elasto-Plastic Behavior of Aluminum Foams Subjected to Compression Loading. Int Appl Mech 53, 356–360 (2017). https://doi.org/10.1007/s10778-017-0818-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10778-017-0818-2