Abstract

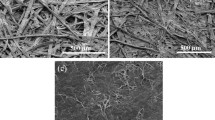

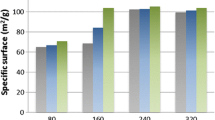

Tissue furnish optimization plays a key role in enhancing tissue properties, making the process cost-effective. Typically, this furnish is composed of a mixture of hardwood eucalyptus fibers (HW) and softwood (SW) fibers, which ensure strength and tissue machine runnability. However, the tissue paper production with the maximization of eucalyptus fibers achieves softer papers at less cost, since SW fibers are often more expensive than HW fibers. From this perspective, this study aims to investigate the effect of micro/nano-fibrillated cellulose (MFC/NFC) as an additive, on structural, softness, strength, and water absorption properties of tissue papers, promoting partial or total removal of SW fibers to produce 100% eucalyptus materials. MFC/NFC was characterized in terms of morphological, chemical, and water interaction properties. The results showed that MFC/NFC presents a high bonding surface area, high carboxyl group content and, when incorporated into tissue furnishes, it promotes strong inter-fiber bonds. This evidence was also supported by SEM image analysis methods and FTIR. Additionally, laboratory tissue handsheets with low basis weight were produced and used in the characterization assays. Overall, the results indicated that MFC/NFC improved strength, at the expense of bulk, porosity, softness, and absorption properties. Compared to typical industrial furnish mixtures (75%HW + 25%SW), MFC/NFC enhanced the production of bulkier, porous, and softer structures, but with reduced strength and absorption. It was possible to optimize the furnish composition by using fiber modeling to obtain 3D structure computation simulations with predictive capability. The MFC/NFC proved to be a high-quality additive to improve softness and strength properties.

Graphic abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

References

Abdul Khalil HPS, Davoudpour Y, Islam N, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohyd Polym 99:649–665. https://doi.org/10.1016/j.carbpol.2013.08.069

Alava M, Niskanen K (2006) The physics of paper. Rep Prog Phys 69:669–723. https://doi.org/10.1088/0034-4885/69/3/R03

Ang S, Haritos V, Batchelor W (2020) Cellulose nanofibers from recycled and virgin wood pulp: A comparative study of fiber development. Carbohyd Polym 234:115900. https://doi.org/10.1016/j.carbpol.2020.115900

Beuther PD, Veith WV, Zwick KJ (2010) Characterization of absorbent flow rate in towel and tissue. J Eng Fiber Fabr 5:1–7. https://doi.org/10.1177/155892501000500201

Bloch J-F, Engin M, Sampson WW (2019) Grammage dependence of paper thickness. Appita J 72:30–40

Brodin FW, Theliander H (2013) A comparison of softwood and birch kraft pulp fibers as raw materials for production of TEMPO-oxidized pulp, MFC and superabsorbent foam. Cellulose 20:2825–2838. https://doi.org/10.1007/s10570-013-0037-x

Chauhan VS, Kumar N, Kumar M, Chakrabarti SK, Thapar SK (2011) Effect of separate and mixed refining of hardwood and softwood pulps on paper properties. J Korea TAPPI 43:1–10

Chang C-H, Yu S-T, Perng Y-S (2018) Effects of furnish and refining on properties of household paper. Cellulose Chem Technol 52:433–440

Chen W, Li Q, Cao J, Liu Y, Li J, Zhang J, Luo S, Yu H (2015) Revealing the structures of cellulose nanofiber bundles obtained by mechanical nanofibrillation via TEM observation. Carbohyd Polym 117:950–956. https://doi.org/10.1016/j.carbpol.2014.10.024

Conceição ELT, Curto JMR, Simões RMS, Portugal ATG (2010) Coding a simulation model of the 3D structure of paper. In: Barneva RP, Brimkov VE, Hauptman HA, Natal Jorge RM, Tavares JMRS (eds) Computational Modeling of Objects Represented in Images. CompIMAGE 2010. Lecture Notes in Computer Science, vol 6026. Springer, Berlin, Heidelberg, pp 299–310. https://doi.org/https://doi.org/10.1007/978-3-642-12712-0_27

Costa VLD, Costa AP, Simões RMS (2019) Nanofibrillated cellulose rheology, effects of morphology, ethanol/acetone addition, and high NaCl concentration. BioRes 14:7636–7654. https://doi.org/10.15376/biores.14.4.7636-7654

Curto JMR, Conceição ELT, Portugal ATG, Simões RMS (2009) The fiber coarseness and collapsibility influence on a three dimension paper model. Proceedings of the 63rd Appita Annual Conference and Exhibition, Melbourne, Australia, pp 303–310

Curto JMR, Conceição ELT, Portugal ATG, Simões RMS (2011) Three dimensional modeling of fibrous materials and experimental validation. Materialwiss Werkstofftech 42:370–374. https://doi.org/10.1002/mawe.201100790

de Assis T, Reisinger LW, Pal L, Pawlak J, Jameel H, Gonzalez RW (2018a) Understanding the effect of machine technology and cellulosic fibers on tissue properties—a review. BioRes 13:4593–4629. https://doi.org/10.15376/biores.13.2.DeAssis

de Assis CA, Iglesias MC, Bilodeau M, Johnson D, Phillips R, Peresin MS, Bilek EM, Rojas OJ, Venditti R, Gonzalez R (2018b) Cellulose micro- and nanofibrils (CMNF) manufacturing - financial and risk assessment. Biofuels Bioprod Bioref 12:251–264. https://doi.org/10.1002/bbb.1835

Dutt D, Tyagi CH (2011) Comparison of various eucalyptus species for their morphological, chemical, pulp and paper making characteristics. Indian J Chem Technol 18:145–151

Fišerová M, Gigac J, Stankovská OE (2019) Influence of bleached softwood and hardwood kraft pulps on tissue paper properties. Cellulose Chem Technol 53:469–477. https://doi.org/10.35812/CelluloseChemTechnol.2019.53.47

Foelkel C (2007) The eucalyptus fibers and the kraft pulp quality requirements for paper manufacturing. Eucalyptus Online Book & Newsletter. https://www.eucalyptus.com.br/capitulos/ENG03_fibers.pdf. Accessed 26 March 2020

Foelkel C (2009) Papermaking properties of Eucalyptus trees, woods and pulp fibers. Eucalyptus Online Book & Newsletter. https://www.eucalyptus.com.br/eucaliptos/ENG14.pdf.Accessed26 March 2020

Gharehkhani S, Sadeghinezhad E, Kazi SN, Yarmand H, Badarudin A, Safaei MR, Zubir MNM (2015) Basic effects of pulp refining on fiber properties—A review. Carbohyd Polym 115:785–803. https://doi.org/10.1016/j.carbpol.2014.08.047

Gigac J, Fišerová M (2008) Influence of pulp refining on tissue paper properties. Tappi J 7:27–32

Ginebreda A, Guillén D, Barceló D, Darbra RM (2011) Additives in the Paper Industry. In: Bilitewski B, Darbra RM, Barceló D (eds) Global Risk-Based Management of Chemical Additives I: Production, Usage and Environmental Occurrence, 1st edn. Springer-Verlag Berlin Heidelberg, pp 11–34. https://doi.org/10.1007/698_2011_109

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in Eucalyptus pulps. BioRes 7:5167–5180. https://doi.org/10.15376/biores.7.4.5167-5180

Gonzalez RW, Zambrano FJ, Jameel H, Venditti RA, Pal L (2020) Tissue paper with reduced fiber and methods of manufacture. (WO Patent No. WO2020112955A1). WIPO IP Portal.

Gu F, Wang W, Cai Z, Xue F, ** Y, Zhu JY (2018) Water retention value for characterizing fibrillation degree of cellulosic fibers at micro and nanometer scales. Cellulose 25:2861–2871. https://doi.org/10.1007/s10570-018-1765-8

Guan M, An X, Liu H (2019) Cellulose nanofiber (CNF) as a versatile filler for the preparation of bamboo pulp based tissue paper handsheets. Cellulose 26:2613–2624. https://doi.org/10.1007/s10570-018-2212-6

Hollmark H, Ampulski RS (2004) Measurement of tissue paper softness: a literature review. Nord Pulp Pap Res J 19:345–353. https://doi.org/10.3183/npprj-2004-19-03-p345-353

Hotaling NA, Bharti K, Kriel H, Simon CG Jr (2015) DiameterJ: a validated open source nanofiber diameter measurement tool. Biomaterials 61:327–338. https://doi.org/10.1016/j.biomaterials.2015.05.015

Hubbe MA (2006) Bonding between cellulosic fibers in the absence and presence of dry-strength agents—a review. BioRes 1:281–318

Hubbe MA, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibers during paper manufacture. BioRes 2:500–533. https://doi.org/10.15376/biores.2.3.500-533

Hubbe MA, Tayeb P, Joyce M, Tyagi P, Kehoe M, Dimic-Misic Pal L (2017) Rheology of nanocellulose-rich aqueous suspensions: a review. BioRes 12(4):9556–9661

Jones BW, Venditti R, Park S, Jameel H, Koo B (2013) Enhancement in enzymatic hydrolysis by mechanical refining for pretreated hardwood lignocellulosics. Bioresour Technol 147:353–360. https://doi.org/10.1016/j.biortech.2013.08.030

Joutsimo OP, Asikainen S (2013) Effect of fiber wall pore structure on pulp sheet density of softwood kraft pulp fibers. BioRes 8:2719–2737

Kibblewhite RP, Riddell MJC (2000) Wood and kraft fibre property variation within and among nine trees of Eucalyptus nitens. Appita J 53:237–244

Klemm D, Cranston ED, Fischer D, Gama M, Kedzior SA, Kralisch D, Kramer F, Kondo T, Lindström T, Nietzsche S, Petzold-Welcke K, Rauchfuß, (2018) Nanocellulose as a natural source for groundbreaking applications in materials science: today’s state. Mater Today 21:720–748. https://doi.org/10.1016/j.mattod.2018.02.001

Kullander J, Nilsson L, Barbier C (2012) Evaluation of furnishes for tissue manufacturing; suction box dewatering and paper testing. Nord Pulp Pap Res J 27:143–150. https://doi.org/10.3183/npprj-2012-27-01-p143-150

Laine C, Wang X, Tenkanen M, Varhimo A (2004) Changes in the fiber wall during refining of bleached pine kraft pulp. Holzforschung 58:233–240. https://doi.org/10.1515/HF.2004.036

Lavoine N, Desloges I, Dufrresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohyd Polym 90:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Lavoine N, Desloges I, Manship B, Bras J (2015) Antibacterial paperboard packaging using microfibrillated cellulose. J Food Sci Technol 52:5590–5600. https://doi.org/10.1007/s13197-014-1675-1

Lin N, Dufresne A (2014) Nanocellulose in biomedicine: current status and future prospect. Eur Polym J 59:302–325. https://doi.org/10.1016/j.eurpolymj.2014.07.025

Lin X, Wu Z, Zhang C, Liu S, Nie S (2018) Enzymatic pul** of lignocellulosic biomass. Ind Crops Prod 120:16–24. https://doi.org/10.1016/j.indcrop.2018.04.033

Lourenço AF, Gamelas JAF, Sarmento P, Ferreira PJT (2019a) Enzymatic nanocellulose in papermaking—The key role as filler flocculant and strengthening agent. Carbohyd Polym 224:115200. https://doi.org/10.1016/j.carbpol.2019.115200

Lourenço AF, Gamelas JAF, Sarmento P, Ferreira PJT (2020) Cellulose micro and nanofibrils as coating agent for improved printability in office papers. Cellulose. https://doi.org/10.1007/s10570-020-03184-9

Lourenço AF, Godinho D, Gamelas JAF, Sarmento P, Ferreira PJT (2019b) Carboxymethylated cellulose nanofibrils in papermaking: influence on filler retention and paper properties. Cellulose 26:3489–3502. https://doi.org/10.1007/s10570-019-02303-5

Maaoui A, Haouari M, Bel Haj Mohamed N, Ben Ouada H, Bulou A (2017) Removal of hydroxyl groups from Er 3+ /Yb 3+ codoped flurotellurite glasses. Mater Res Bull 93:325–332. https://doi.org/10.1016/j.materresbull.2017.05.020

Martins VDF, Cerqueira MA, Fuciños P, Garrido-Maestu A, Curto JMR, Pastrana LM (2018) Active bi-layer cellulose-based films: development and characterization. Cellulose 25:6361–6375. https://doi.org/10.1007/s10570-018-2021-y

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials 6:1745–1766. https://doi.org/10.3390/ma6051745

Moberg T, Sahlin K, Tao K, Geng S, Westman G, Xhou Q, Oksman K, Rigdahl M (2017) Rheological properties of nanocellulose suspensions: effects of fibril/particle dimensions and surface characteristics. Cellulose 24:2499–2510. https://doi.org/10.1007/s10570-017-1283-0

Morais FP, Bértolo RAC, Curto JMR, Amaral MECC, Carta AMMS, Evtyugin DV (2019) Comparative characterization of eucalyptus fibers and softwood fibers for tissue papers applications. Mat Lett X 4:100028. https://doi.org/10.1016/j.mlblux.2019.100028

Morais FP, Bértolo RAC, Curto JMR, Amaral MECC, Carta AMMS, Evtyugin DV (2020a) Characterization data of pulp fibres performance in tissue papers applications. Data Brief 29:105253. https://doi.org/10.1016/j.dib.2020.105253

Morais FP, Carta AMMS, Amaral ME, Curto JMR (2020b) 3D fiber models to simulate and optimize tissue materials. BioRes 15:8833–8848. https://doi.org/10.15376/biores.15.4.8833-8848

Morais FP, Carta AMMS, Amaral ME, Curto JMR (2021) Cellulose fiber enzymatic modification to improve the softness strength, and absorption properties of tissue papers. BioRes 16:846–861. https://doi.org/10.15376/biores.16.1.846-861

Muneri A (1997) Kraft pul** properties of acacia mearnsii and eucalyptus grandis grown in zimbabwe. South Afr J 179:13–19. https://doi.org/10.1080/10295925.1997.9631148

Nasir M, Hashim R, Sulaiman O, Asim M (2017) Nanocellulose: Preparation methods and applications. In: Mohammad J, Sami B, Abdul Khalil HPS (eds) Cellulose-Reinforced Nanofibre Composites: Production, Properties and Applications, 1st edn. Elsevier, Amsterdam, pp 261–276. https://doi.org/https://doi.org/10.1016/B978-0-08-100957-4.00011-5

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromol 17:2311–2320. https://doi.org/10.1021/acs.biomac.6b00668

Neiva D, Fernandes L, Araújo S, Lourenço A, Gominho J, Simões R, Pereira H (2015) Chemical composition and kraft pul** potential of 12 eucalypt species. Ind Crops Prod 66:89–95. https://doi.org/10.1016/j.indcrop.2014.12.016

Nie S, Zhang K, Lin X, Zhang C, Yan D, Liang H, Wang S (2018) Enzymatic pretreatment for the improvement of dispersion and film properties of cellulose nanofibrils. Carbohyd Polym 181:1136–1142. https://doi.org/10.1016/j.carbpol.2017.11.020

Paavilainen L (1990) Importance of particle size - fiber length and fines – for characterization of softwood kraft pulp. Pap Puu 72:516–526

Park JY, Melani L, Lee H, Kim HJ (2019) Effect of chemical additives on softness components of hygiene paper. Nord Pulp Pap Res J 34:173–181. https://doi.org/10.1515/npprj-2019-0002

Patiño-Masó J, Serra-Parareda F, Tarrés Q, Mutjé P, Espinach FX, Delgado-Aguilar M (2019) TEMPO-oxidized cellulose nanofibers: a potential bio-based superabsorbent for diaper production. Nanomaterials 9:1271. https://doi.org/10.3390/nano9091271

Raunio J-P, Ritala R (2013) Method for detecting free fiber ends in tissue paper. Meas Sci Technol 24:125206. https://doi.org/10.1088/0957-0233/24/12/125206

Roy S, Zhai L, Hai LV, Kim JW, Park JH, Kim HC, Kim J (2018) One-step nanocellulose coating converts tissue paper into an efficient separation membrane. Cellulose 25:4871–4886. https://doi.org/10.1007/s10570-018-1945-6

Sanchez-Salvador JL, Balea A, Monte MC, Negro C, Miller M, Olson J, Blanco A (2020) Comparison of mechanical and chemical nanocellulose as additives to reinforce recycled cardboard. Sci Rep 10:3778. https://doi.org/10.1038/s41598-020-60507-3

Shannon TG, Soerens DA (2004) Strength Additives for Tissue Products (U.S. Patent No. 2004/0118541A1). United States Patent Application Publication

Silvy J, Romatier G, Chiodi R (1968) Méthodes pratiques de controle du raffinage. ATIP 22:31–53

Siqueira EJ, Salon MCB, Belgacem MN, Mauret E (2015) Carboxymethylcellulose (CMC) as a model compound of cellulose fibers and polyamideamine epichlorohydrin (PAE)–CMC interactions as a model of PAE–fibers interactions of PAE-based wet strength papers. J Appl Polym Sci 132:42144. https://doi.org/10.1002/APP.42144

Smith DK, Bampton RF, Alexander WJ (1963) Use of new solvents for evaluating chemical cellulose for the viscose process. Ind Eng Chem Proc DD 2:57–62. https://doi.org/10.1021/i260005a012

Stankovská M, Gigac J, Fišerová M, Opálená E (2018) Relationship between structural parameters and water absorption of bleached softwood and hardwood kraft pulps. Wood Res 64:261–272

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. https://doi.org/10.1007/s10570-010-9431-9

Tanaka R, Saito T, Ishii D, Isogai A (2014) Determination of nanocellulose fibril length by shear viscosity measurement. Cellulose 21:1581–1589. https://doi.org/10.1007/s10570-014-0196-4

Tarrés Q, Delgado-Aguilar M, Pèlach MA, González I, Boufi S, Mutjé P (2016) Remarkable increase of paper strength by combining enzymatic cellulose nanofibers in bulk and TEMPO-oxidized nanofibers as coating. Cellulose 23:3939–3950. https://doi.org/10.1007/s10570-016-1073-0

Tourtollet GEP, Cottin F, Cochaux A, Petit-Conil M (2003) The use of MorFi analyser to characterize mechanical pulps. Proceedings of the International Mechanical Pul** Conference, Quebec City, Canada, pp 225–232

Trepanier R (2017) Pulp fiber quality and the relationship with paper tissue properties. Tappi Tissue, pp 1–4

Uematsu T, Matsui Y, Kakiuchi S, Isogai A (2011) Cellulose wet wiper sheets prepared with cationic polymer and carboxymethyl cellulose using a papermaking technique. Cellulose 18:1129–1138. https://doi.org/10.1007/s10570-011-9536-9

Vieira JC, Mendes AO, Carta AM, Fiadeiro PT, Costa AP (2020) Experimental dataset supporting the physical and mechanical characterization of industrial base tissue papers. Data Brief 33:106434. https://doi.org/10.1016/j.dib.2020.106434

Wang Y, Zambrano F, Venditti R, Dasmohapatra S, de Assis T, Reisinger L, Pawlak J, Gonzalez R (2019) Effect of pulp properties, drying technology, and sustainability on bath tissue performance and shelf price. BioRes 14:9410–9428. https://doi.org/10.15376/biores.14.4.9410-9428

Wang Y, de Assis T, Zambrano F, Pal L, Venditti R, Dasmohapatra S, Pawlak J, Gonzalez R (2019) Relationship between human perception of softness and instrument measurements. BioRes 14:780–795. https://doi.org/10.15376/biores.14.1.780-795

** W, Liu W, Dang Y, Peng Y (2019) Multi-scale modelling of the tensile behavior of lithium ion battery cellulose separator. Polym Int 68:1341–1350. https://doi.org/10.1002/pi.5823

Zambrano F, Starkey H, Wang Y, de Assis CA, Venditti R, Pal L, Jameel H, Hubbe MA, Rojas OJ, Gonzalez R (2020) Using micro- and nanofibrillated cellulose as a means to reduce weight of paper products: a review. BioRes 15:4553–4590

Zambrano F, Wang Y, Zwilling JD, Venditti R, Jameel H, Rojas O, Gonzalez R (2021) Micro- and nanofibrillated cellulose from virgin and recycled fibers: a comparative study of its effects on the properties of hygiene tissue paper. Carbohyd Polym. https://doi.org/10.1016/j.carbpol.2020.117430

Zhang L, Batchelor W, Varanasi S, Tsuzuki T, Wang X (2012) Effect of cellulose nanofiber dimensions on sheet forming through filtration. Cellulose 19:561–574. https://doi.org/10.1007/s10570-011-9641-9

Zhang K, Zhang Y, Yan D, Zhang C, Nie S (2018) Enzyme-assisted mechanical production of cellulose nanofibrils: thermal stability. Cellulose 25:5049–5061. https://doi.org/10.1007/s10570-018-1928-7

Acknowledgments

This research was supported by Project InPaCTus – Innovative Products and Technologies from eucalyptus, Project Nº 21 874 funded by Portugal 2020 through European Regional Development Fund (ERDF) in the frame of COMPETE 2020 nº 246/AXIS II/2017. The authors are also very grateful for the support given by Fiber Materials and Environmental Technologies Research Unit (FibEnTech-UBI) on the extent of the project reference UIDB/00195/2020.

Author information

Authors and Affiliations

Contributions

The manuscript was written through the contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Morais, F.P., Carta, A.M.M.S., Amaral, M.E. et al. Micro/nano-fibrillated cellulose (MFC/NFC) fibers as an additive to maximize eucalyptus fibers on tissue paper production. Cellulose 28, 6587–6605 (2021). https://doi.org/10.1007/s10570-021-03912-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03912-9