Abstract

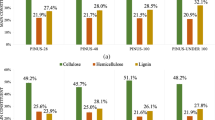

The species Eucalyptus globulus, Eucalyptus nitens and Pinus radiata, are important supplies for the production of cellulose pulp in the world market, which can be used for the production of cellulose nanofibrils (CNFs). Understanding how the characteristics of different raw materials affect the production and final properties of nanofibrillated celluloses is very useful, both for the pulp industry and for the end user. The aim of this research was to determine how the chemical and structural differences of the commercial Kraft pulps of E. globulus, E. nitens and P. radiata affect the production and the morphological and rheological characteristics of the CNFs produced through an enzymatic-mechanical process. On one hand, the results showed that pine fibers were easier to deconstruct than eucalyptus fibers, however, pine CNFs were found to have the largest fibril width and a lower aspect ratio (length /width). On the other hand, the pulp of E. globulus, was the one that obtained a better aspect ratio and higher intrinsic viscosity.

Similar content being viewed by others

References

Aksenov AS, Tyshkunova IV, Poshina DN, Guryanova AA, Chukhchin DG, Sinelnikov IG, Synitsyn AP (2020) Biocatalysis of Industrial Kraft Pulps: Similarities and Differences between Hardwood and Softwood Pulps in Hydrolysis by Enzyme Complex of Penicillium verruculosum. Catalysts 10(5):536

Albornoz-Palma G, Betancourt F, Mendonça RT, Chinga-Carrasco G, Pereira M (2020a) Relationship between rheological and morphological characteristics of cellulose nanofibrils in dilute dispersions. Carbohydrate Polymers, 115588

Albornoz-Palma G, Ching D, Valerio O, Mendonça RT, Pereira M (2020b) Effect of lignin and hemicellulose on the properties of lignocellulose nanofibril suspensions. Cellulose 27:10631–10647

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861

Antes R, Joutsimo OP (2015a) Fiber surface and paper technical properties of Eucalyptus globulus and Eucalyptus nitens pulps after modified cooking and bleaching. BioResources 10(1):1599–1616

Antes R, Joutsimo OP (2015b) Effect of modified cooking on bleachability of Eucalyptus globulus and Eucalyptus nitens. BioResources 10(1):597–612

Aguayo MG, Quintupill L, Castillo R, Baeza J, Freer J, Mendonça RT (2010) Determination of differences in anatomical and chemical characteristics of tension and opposite wood of 8-year-old Eucalyptus globulus. Maderas Ciencia y tecnologia 12(3):241–251

Andrade A, Pereira S (2019) Producción y usos de la celulosa nanofibrilada y microfibrilada: ‘‘Métodos de deconstrucción de la pared celular”. Transferencia tecnológica sobre aplicaciones de nanocelulosa en Iberoamérica), Programa Iberoamericano de Ciencia y Tecnología para el Desarrollo (CYTED), 1st edn, pp 36–38

Barrera Pedraza D (2018) Celulosa chilena: Avances y perspectiva de su comercio exterior: enero de 2018. Oficina deEstudios y Politicas Agrarias (ODEPA). Chile, pp 9–12

Besbes I, Vilar MR, Boufi S (2011) Nanofibrillated cellulose from alfa, eucalyptus and pine fibres: preparation, characteristics and reinforcing potential. Carbohyd Polym 86(3):1198–1206

Carrillo I, Mendonça RT, Ago M, Rojas OJ (2018a) Comparative study of cellulosic components isolated from different Eucalyptus species. Cellulose 25(2):1011–1029

Carrillo I, Vidal C, Elissetche JP, Mendonça RT (2018b) Wood anatomical and chemical properties related to the pulpability of Eucalyptus globulus: a review. Southern Forests: a Journal of Forest Science 80(1):1–8

Chaker A, Alila S, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20(6):2863–2875

Chakraborty A, Sain M, Kortschot M (2006) Reinforcing potential of wood pulp-derived microfibres in a PVA matrix. Holzforschung 60(1):53–58

Chen Y, Geng B, Ru J, Tong C, Liu H, Chen J (2017) Comparative characteristics of TEMPO-oxidized cellulose nanofibers and resulting nanopapers from bamboo, softwood, and hardwood pulps. Cellulose 24(11):4831–4844

Chen M, **a L, Xue P (2007) Enzymatic hydrolysis of corncob and ethanol production from cellulosic hydrolysate. Int Biodeter Biodegrad 59(2):85–89

Chinga-Carrasco G, Yu Y, Diserud O (2011) Quantitative electron microscopy of cellulose nanofibril structures from Eucalyptus and Pinus radiata kraft pulp fibers. Microsc Microanal 17(4):563

Chinga-Carrasco G (2011) Cellulose fibres, nanofibrils and microfibrils: the morphological sequence of MFC components from a plant physiology and fibre technology point of view. Nanoscale Res Lett 6(1):1–7

De Carvalho DM, Moser C, Lindström ME, Sevastyanova O (2019) Impact of the chemical composition of cellulosic materials on the nanofibrillation process and nanopaper properties. Ind Crops Prod 127:203–211

Delgado Aguilar M (2015) Nanotecnología en el sector papelero: mejoras en calidad y permanencia de las fibras de alto rendimiento y secundarias en una economía circular mediante el uso de nanofibras y el refino enzimático (tesis doctoral), Universitat de Girona

Duchesne I, Hult E, Molin U, Daniel GI, Lennholm H (2001) The influence of hemicellulose on fibril aggregation of kraft pulp fibres as revealed by FE-SEM and CP/MAS 13 C-NMR. Cellulose 8(2):103–111

Espinosa E, Tarres Q, Delgado-Aguilar M, Gonzalez I, Mutje P, Rodriguez A (2016) Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibres and their application to papermaking slurries. Cellulose 23(1):837–852

Ferraz A, Baeza J, Rodriguez J, Freer J (2000) Estimating the chemical composition of biodegraded pine and eucalyptus wood by DRIFT spectroscopy and multivariate analysis. Biores Technol 74(3):201–212

Foster EJ, Moon RJ, Agarwal UP, Bortner MJ, Bras J, Camarero-Espinosa S et al (2018) Current characterization methods for cellulose nanomaterials. Chem Soc Rev 47(8):2609–2679

Gharehkhani S, Sadeghinezhad E, Kazi SN, Yarmand H, Badarudin A, Safaei MR, Zubir MNM (2015) Basic effects of pulp refining on fiber properties: a review. Carbohydr Polym 115:785–803

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59(2):257–268

Gómez EA, Ríos LA, Peña JD (2012) Madera, un potencial material lignocelulósico para la producción de biocombustibles en Colombia. Inform Tecnol 23(6):73–86

He M, Yang G, Chen J, Ji X, Wang Q (2018) Production and characterization of cellulose nanofibrils from different chemical and mechanical pulps. J Wood Chem Technol 38(2):149–158

Hinestroza J, Netravali AN (2014) Cellulose based composites: new green nanomaterials. Wiley, Hoboken

Honorato C, Kumar V, Liu J, Koivula H, Xu C, Toivakka M (2015) Transparent nanocellulose-pigment composite films. J Mater Sci 50(22):7343–7352

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19(1):137–145

Igartúa D, Monteoliva S (2010) Densidad básica, longitud de fibras y crecimiento en dos procedencias de Eucalyptus globulus en Argentina. Bosque (Valdivia) 31(2):150–156

ISO 5263–1 (2004) Pulps–Laboratory wet disintegration–Part 1: Disintegration of chemical pulps

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromol 9(3):1022–1026

Iwamoto S, Lee S-H, Endo T (2014) Relationship between aspect ratio and suspension viscosity of wood cellulose nanofibers. Polym J 46:73

**guang Hu, Tian D, Renneckar S, Saddler JN (2018) Enzyme mediated nanofibrillation of cellulose by the synergistic actions of an endoglucanase, lytic polysaccharide monooxygenase (LPMO) and xylanase. Nat Sci Rep 8:3195

Kumagai A, Endo T (2018) Comparison of the surface constitutions of hemicelluloses on lignocellulosic nanofibers prepared from softwood and hardwood. Cellulose 25(7):3885–3897

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose: Its barrier properties and applications in cellulosic materials: a review. Carbohyd Polym 90:735–764

Li Q (2012) Nanocellulose: preparation, characterization, supramolecular modeling, and its life cycle assessment (Doctoral dissertation, Virginia Tech)

Li W, Wang R, Liu S (2011) Nanocrystalline cellulose prepared from softwood kraft pulp via ultrasonic-assisted acid hydrolysis. BioResources 6(4):4271–4281

Loijas M (2010) Factors affecting the axial force in low-consistency refining. Tampere University of Applied Science, Tampere

Martínez P, Pereira M, Mendonça RT (2015) Retention and structure of xylans from E. globulus genotypes with different pulpwood characteristics. J Wood Chem Technol 35(2):129–136

Mendonça RT, Jara JF, Gonzalez V, Elissetche JP, Freer J (2008) Evaluation of white root fungi Ganoderma australe and Ceriporiopsis subvermispora in biotechnological applications. J Ind Microbiol Biotechnol 35:1323–1313

Miranda I, Almeida MH, Pereira H (2001) Variation of fibre biometry in different provenances of E. globulus Labill. Appita J 54(3):272–280

Naderi A, Lindström T (2015) Rheological measurements on nanofibrillated cellulose systems: a science in progress. In: Mondal MIH (ed) Cellulose and cellulose derivatives: synthesis, modification and applications. Nova Science Publisher, Inc. pp 187–202

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8(6):1934–1941

Raymond CA, Muneri A (2001) Nondestructive sampling of E. globulus and E. nitens for wood properties. I. Basic density. Wood Sci Technol 35:27–39

Reyes P, Aguayo MG, Martínez P, Freer J, Pereira M, Mendonça RT (2012) Biorefinería forestal: Extracción de hemicelulosas de Pinus radiata para la obtención de bioetanol integrada a la producción de celulosa kraft

Saarinen T, Haavisto S, Sorvari A, Salmela J, Seppälä J (2014) The effect of wall depletion on the rheology of microfibrillated cellulose water suspensions by optical coherence tomography. Cellulose 21(3):1261–1275

Stelte W, Sanadi AR (2009) Preparation and characterization of cellulose nanofibers from two commercial hardwood and softwood pulps. Ind Eng Chem Res 48(24):11211–11219

Stoere P, Nazhad M, Kerekes R (2001) Experimental study of the effect of refining on paper formation. Tappi J 84(7):1–9

Syverud K, Chinga-Carrasco G, Toledo J, Toledo PG (2011) A comparative study of Eucalyptus and P. radiata pulp fibres as raw materials for production of cellulose nanofibrils. Carbohydr Polym 84:1033–1038

Tanaka R, Saito T, Hondo H, Isogai A (2015) Influence of flexibility and dimensions of nanocelluloses on the flow properties of their aqueous dispersions. Biomacromol 16(7):2127–2131

Tarrés Q, Saguer E, Pèlach MA, Alcalà M, Delgado-Aguilar M, Mutjé P (2016a) The feasibility of incorporating cellulose micro/nanofibers in papermaking processes: the relevance of enzymatic hydrolysis. Cellulose 23(2):1433–1445

Tarrés Q, Delgado-Aguilar M, Pèlach M, González I, Boufi S, Mutjé P (2016b) Remarkable increase of paper strength by combining enzymatic cellulose nanofibers in bulk and tempo-oxidized nanofibers as coating. Cellulose 23:3939–3950

Tokimatsu K, Tamura S, Kojima H (1992) Effects of multiple modes on Rayleigh wave dispersion characteristics. J Geotech Eng 118(10):1529–1543

Turbak AF, Snyder FW, Sandberg KR Micro-fibrillated cellulose and process for producing it. 1985; Patent no CH 648071 (A5)

Vallejos María Evangelina (2019) La celulosa nanofibrilada en el contexto de la biorrefinería.Transferencia tecnológica sobre aplicaciones de nanocelulosa en Iberoamérica), Programa Iberoamericano de Ciencia y Tecnología para el Desarrollo (CYTED), 1st edn, pp 2–16

Acknowledgments

We thank to: ANID-Subdirección de Capital Humano/Doctorado Nacional/2020-21202153, ANID-Subdirección de Capital Humano/Doctorado Nacional/2018-21181080, the ASIF laboratory (Department of Chemical Engineering, Universidad de Concepción, Eng. Carlos Oliveros, FPC Papeles SpA (Eng. Juan Fritz, PhD. Eduardo Izquierdo and quality control laboratory) and project FONDECYT Nº1201042.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Andrade, A., Henríquez-Gallegos, S., Albornoz-Palma, G. et al. Effect of the chemical and structural characteristics of pulps of Eucalyptus and Pinus on the deconstruction of the cell wall during the production of cellulose nanofibrils. Cellulose 28, 5387–5399 (2021). https://doi.org/10.1007/s10570-021-03848-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03848-0