Abstract

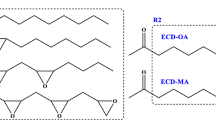

This work deals with the selective incorporation of reactive isocyanate groups into methyl cellulose in order to be used as reactive thickening agent in castor oil. Resulting gel-like dispersions may have potential applications as green lubricating greases formulated from renewable resources. Two different isocyanate-functionalized methyl cellulose-based polymers were obtained by reaction of methyl cellulose with 1,6-hexamethylene diisocyanate. The functionalization degree, from fully functionalized to a certain number of free hydroxyl groups (58:36:6 ratio between –OMe, –NCO and free –OH groups), was controlled by modifying the reagents molar ratio. These polymers were characterized through nuclear magnetic resonance of protons (1H-NMR), Fourier transform infrared spectroscopy and thermogravimetric analysis (TGA). Thermal and rheological responses of oleogels prepared by dispersing these polymers in castor oil were studied by means of TGA analysis and small-amplitude oscillatory shear measurements. The evolution of linear viscoelasticity functions with frequency of the oleogel containing isocyanate-functionalized methyl cellulose with lower –NCO content is quite similar to that found for traditional lithium lubricating greases. In relation to long-term stability of these oleogels, the values of viscoelastic functions significantly increase during the first 7 days of ageing and then remain almost constant.

Similar content being viewed by others

References

Anzuino G, Pirro A, Rossi O, Friz LP (1975) Reaction of diisocyanates with alcohols. I. Uncatalyzed reactions. J Polym Sci Part A Polym Chem 13:1657–1666

Erhan SZ, Sharma BK, Perez JM (2006) Oxidation and low temperature stability of vegetable oil-based lubricants. Ind Crops Prod 24:292–299

Franco JM, Delgado MA, Valencia C, Sánchez MC, Gallegos C (2005) Mixing rheometry for studying the manufactured of lubricating greases. Chem Eng Sci 60:2409–2418

Gao L, Liu YH, Lei H, Peng H, Ruan R (2010) Preparation of semirigid polyurethane foam with liquefied bamboo residues. J Appl Polym Sci 116:1694–1699

Girones J, Pimenta MTB, Vilaseca F, Carvalho AJF, Mutje P, Curvelo AAS (2007) Blocked diisocyanates as coupling agents for cellulose-based composites. Carbohydr Polym 68:537–543

Girones J, Pimenta MTB, Vilaseca F, Carvalho AJF, Mutje P, Curvelo AAS (2008) Blocked diisocyanates as reactive coupling agents: application to pine fiber-polypropylene composites. Carbohydr Polym 74:106–113

Gradinaru LM, Mandru M, Ciobanu C, Filip D, Macocinschi D, Vlad S (2011) Influence of diisocyanate structure on the properties of some polyetherurethanes based on renewable resources. J Optoelectron Adv Mater 13:280–286

Greene TW, Wuts PGM (1991) Protective groups in organic synthesis, 3rd edn. Wiley, New York

Gupta RK (2000) Polymer and composite rheology, 2nd edn. Marcel Dekker, New York

Kurihara K, Ata M, Matsute M, Watanabe H, Seto J (1997) Estimation of reactivity of isocyanate groups by calculation and magnetochemical measurement. Jpn J Appl Phys 36:5317

Lea CW (2002) European development of lubricant derived from renewable resources. Ind Lubr Tribol 54:268–274

Li Y, Ren H, Ragauskas AJ (2011) Rigid polyurethane foam/cellulose whisker nanocomposites: preparation, characterization, and properties. J Nanosci Nanotechnol 11:6904–6911

Lu L, Liu X, Tong Z (2006) Critical exponents for sol–gel transition in aqueous alginate solutions induced by cupric cations. Carbohydr Polym 65:544–551

Ly B, Thielemans W, Dufresne A, Chaussy D, Belgacem MN (2008) Surface functionalization of cellulose fibres and their incorporation in renewable polymeric matrices. Compos Sci Technol 68:3193–3201

Martín-Alfonso JE, Yañez R, Valencia C, Franco JM, Diaz MJ (2009a) Optimization of the methylation conditions of Kraft cellulose pulp for its use as a thickener agent in biodegradable lubricating greases. Ind Eng Chem Res 48:6765–6771

Martín-Alfonso JE, Valencia C, Sánchez MC, Franco JM, Gallegos C (2009b) Rheological modification of lubricating greases with recycled polymers from different plastics waste. Ind Eng Chem Res 48:4136–4144

Martín-Alfonso JE, Núñez N, Valencia C, Franco JM, Diaz MJ (2011a) Formulation of new biodegradable lubricating greases using ethylated cellulose pulp as thickener agent. J Ind Eng Chem 17:818–823

Martín-Alfonso JE, Valencia C, Sánchez MC, Franco JM, Gallegos C (2011b) Evaluation of different polyolefins as rheology modifier additives in lubricating grease formulations. Mater Chem Phys 128:530–538

Moreno G, Valencia C, De Paz V, Franco JM, Gallegos C (2006) Use of reactive diisocyanate-terminated polymers as rheology modifiers of lubricating greases. Ind Chem Eng Res 45:4001–4010

Moreno G, Valencia C, Franco JM, Gallegos C, Diogo A, Bordado JCM (2008) Influence of molecular weight and free NCO content on the rheological properties of lithium lubricating greases modified with NCO-terminated prepolymers. Eur Polym J 44:2262–2274

Moreno G, De Paz MV, Valencia C, Franco JM (2012) Synthesis and characterization of isocyanate-functionalized PVA-based polymers with applications as new additives in lubricant formulations. J Appl Polym Sci 125:3259–3267

Nourbakhsh A, Kokta BV, Ashori A, Jahan-Latibari A (2008) Effect of a novel coupling agent, polybutadiene isocyanate, on mechanical properties of wood-fiber polypropylene composites. J Reinf Plast Compos 27:1679–1687

Nuñez N, Martin-Alfonso JE, Eugenio ME, Valencia C, Diaz MJ, Franco JM (2011) Preparation and characterization of gel-like dispersions based on cellulosic pulps and castor oil for lubricant applications. Ind Eng Chem Res 50:5618–5627

Nuñez N, Martín-Alfonso JE, Valencia C, Sánchez MC, Franco JM (2012) Rheology of new green lubricating grease formulations containing cellulose pulp and its methylated derivative as thickener agents. Ind Crop Prod 37:500–507

Qiu WL, Zhang FR, Endo T, Hirotsu T (2005) Isocyanate as a compatibilizing agent on the properties of highly crystalline cellulose/polypropylene composites. J Mater Sci 40:3607–3614

Quinchia LA, Delgado MA, Valencia C, Franco JM, Gallegos C (2009) Viscosity modification of high-oleic sunflower oil with polymeric additives for the design of new biolubricant formulations. Environ Sci Technol 43:2060–2065

Quinchia LA, Delgado MA, Valencia C, Franco JM, Gallegos C (2011) Natural and synthetic antioxidant additives for improving the performance of new biolubricant formulations. J Agric Food Chem 59:12917–12924

Rueda L, Fernandez-d’Arlas B, Zhou Q, Berglund LA, Corcuera MA, Mondragon I, Eceiza A (2011) Isocyanate-rich cellulose nanocrystals and their selective insertion in elastomeric polyurethane. Compos Sci Technol 71:1953–1960

Sanchez R, Franco JM, Delgado MA, Valencia C, Gallegos C (2009) Development of new green lubricating grease formulations based on cellulosic derivatives and castor oil. Green Chem 11:686–693

Sanchez R, Stringari GB, Franco JM, Valencia C, Gallegos C (2011a) Use of chitin, chitosan and acylated derivatives as thickener agents of vegetable oils for bio-lubricant applications. Carbohydr Polym 85:705–714

Sanchez R, Franco JM, Delgado MA, Valencia C, Gallegos C (2011b) Thermal and mechanical characterization of cellulosic derivatives-based oleogels potentially applicable as bio-lubricating greases: influence of ethyl cellulose molecular weight. Carbohydr Polym 83:151–158

Sanchez MC, Franco JM, Valencia C, Gallegos C, Urquiola F, Urchequi R (2011c) Atomic force microscopy and thermo-rheological characterisation of lubricating greases. Tribol Lett 41:463–470

Trejo-O’Reilly JA, Cavaille JY, Gandini A (1997) The surface chemical modification of cellulosic fibres in view of their use in composite materials. Cellulose 4:305–320

Vandenabeele-Trambouze O, Mion L, Garrelly L, Commeyras A (2001) Reactivity of organic isocyanates with nucleophilic compounds: amines; alcohols; thiols; oximes; and phenols in dilute organic solutions. Adv Environ Res 6:45–55

Vlad S, Filip D, Macocinschi D, Spiridon I, Nistor A, Gradinaru LM, Musteata VE (2010) New polyetherurethanes based on cellulose derivative for biomedical applications. Optoelectron Adv Mater-Rapid Commun 4:407–414

Wilson B (1998) Lubricants and functional fluids from renewable sources. Ind Lubr Tribol 50:6–15

Acknowledgments

This work is part of a research project (CTQ2010–15338) sponsored by a MINECO-FEDER Programme. One of the authors (R. Gallego) has received a Ph.D. Research Grant from the “Ministerio de Ciencia e Innovación”. The authors gratefully acknowledge its financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gallego, R., Arteaga, J.F., Valencia, C. et al. Chemical modification of methyl cellulose with HMDI to modulate the thickening properties in castor oil. Cellulose 20, 495–507 (2013). https://doi.org/10.1007/s10570-012-9803-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9803-4