Abstract

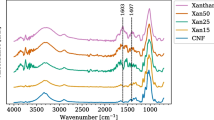

Adsorption isotherms of single and double chain cationic surfactants with different chain length (cetyltrimethyl-, didodecyl- and dihexadecyl ammonium bromide) onto cellulose nanofibrils were determined. Nanofibrillated cellulose, also known as microfibrillated cellulose (MFC), with varying contents of carboxyl groups (different surface charge) was prepared by TEMPO-mediated oxidation followed by mechanical fibrillation. The fibril charge was characterized by potentiometric and conductometric titration. Surfactant adsorption was verified by Fourier Transform Infrared Spectroscopy (FTIR) and X-ray Photoelectron Spectroscopy (XPS). Wetting and adhesion of water onto fibril films was determined by contact angle measurements. Small aggregates (admicelles) of surfactant were shown to form on the nanofibril surfaces, well below critical micelle concentrations. The results demonstrate the possibility of using cationic surfactants to systematically control the degree of water wettability of cellulose nanofibrils.

Similar content being viewed by others

References

Alila S, Boufi S, Belgacem MN, Beneventi D (2005) Adsorption of cationic surfactant onto cellulosic fibers I. Surface charge effects. Langmuir 21:8106–8113

Aloulou F, Boufi S, Beneventi D (2004a) Adsorption of organic compounds onto polyelectrolyte immobilized-surfactant aggregates on cellulosic fibers. J Colloid Interf Sci 280:350–358

Aloulou F, Boufi S, Chakchouk M (2004b) Adsorption of octadecyltrimethylammonium chloride and solubilization on to cellulosic fibers. Colloid Polym Sci 282:699–707

Aloulou F, Boufi S, Belgacem N, Gandini A (2004c) Adsorption of cationic surfactants and subsequent adsolubilization of organic compounds onto cellulose fibers. Colloid Polym Sci 283:344–350

Andresen M, Stenius P (2007) Water-in-oil emulsions stabilized by hydrophobized microfibrillated cellulose. J Dispers Sci Technol 28:837–844

Andresen M, Johansson L-S, Tanem BS, Stenius P (2006) Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 13:655–677

Barthel KU (2004) Interactive 3D surface plot. http://rsb.info.nih.gov/ij/plugins/surface-plot-3d.html

Bruce DM, Hobson RN, Farrent JW, Hepworth DG (2005) High-performance composites from low-cost plant primary cell walls. Compos Part A Appl Sci Manuf 36:1486–1493

Chinga G, Johnsen PO, Dougherty R, Lunden-Berli E, Walter J (2007) Quantification of the 3D microstructures of SC surfaces. J Microsc 227:254–265

Chinga-Carrasco G, Syverud K (2010) Computer-assisted quantification of the multi-scale structure of films made of nanofibrillated cellulose. J Nanopart Res 12:841–851

da Silva Perez D, Montanari S, Vignon MR (2003) TEMPO-mediated oxidation of cellulose III. Biomacromolecules 4:1417–1425

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nordic Pulp Paper Res J 23:299–304

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165

Goussé C, Chanzy H, Excoffier G, Soubeyrand L, Fleury E (2002) Stable suspensions of partially silylated cellulose whiskers dispersed in organic solvents. Polymer 43:2645–2651

Gran G (1952) Determination of the equivalence point in potentiometric titrations. II. Analyst 77:661–671

Helbert W, Cavaillé JY, Dufresne A (1996) Thermoplastic nanocomposites filled with wheat straw cellulose whiskers. Part I: processing and mechanical behavior. Polym Compos 17:604–611

Henriksson M, Henriksson G, Berglund AL, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441

Iwamoto S, Nakagaito AN, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A Mater Sci Proc 81:1109–1112

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A Mate Sci Proc 89:461–466

Kim D-Y, Nishiyama Y, Kuga S (2002) Surface acetylation of bacterial cellulose. Cellulose 9:361–367

Ladouce L, Fleury E, Goussé C, Cantiani R, Chanzy H, Excoffier G (2004) Cellulose nanofibrils with modified surface, preparation method and use thereof—Rhodia Chimie, US 6 703 497

Nakagaito AN, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys A Mater Sci Proc 78:547–552

Nakagaito AN, Yano H (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A Mater Sci Proc 80:155–159

Ougiya H, Watanabe K, Morinaga Y, Yoshinaga F (1997) Emulsion-stabilizing effect of bacterial cellulose. Biosci Biotechnol Biochem 61:1541–1545

Oza KP, Frank SG (1986) Microcrystalline cellulose stabilized emulsions. J Dispers Sci Technol 7:543–561

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson TP, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Partyka S, Kundheimer M, Faucumore B (1993) Aggregate formation at the solid-liquid interface: the calorimetric evidence. Colloids Surf A Physicochem Eng Aspects 76:267–281

Peltonen J, Järn M, Areva S, Linden M, Rosenholm JB (2004) Topographical parameters for specifying a three-dimensional surface. Langmuir 20:9428–9431

Penfold J, Tucker I, Petkov J, Thomas RK (2007) Surfactant adsorption onto cellulose surfaces. Langmuir 23:8357–8364

Rodionova G, Lenes M, Eriksen Ø, Gregersen Ø (2010) Surface chemical modification of microfibrillated cellulose: improvement of barrier properties for packaging applications. Cellulose. doi:10.1007/s10570-010-9474-y

Rosen MJ, Goldsmith HA (1972) Systematic analysis of surface-active agents. Willey-Interscience, New York, p. 457

Rossotti FJC, Rossotti H (1965) Potentiometric titrations using Gran plots-a textbook omission. J Chem Edu 42:375–378

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Scamehorn JF, Schechter RS, Wade WH (1982) Adsorption of surfactants on mineral oxide surfaces from aqueous solutions. I. Isomerically pure anionic surfactants. J Colloid Interf Sci 85:463–478

Stenstad P, Andresen M, Tanem BS, Stenius P (2008) Chemical surface modifications of microfibrillated cellulose. Cellulose 15:35–45

Sui ZM, Chen X, Wang LY, Xu LM, Zhuang WC, Chai YC, Yang CJ (2006) Cap** effect of CTAB on positively charged Ag nanoparticles. Phys E Low Dimens syst nanostruct 33:308–314

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827

Xhanari K, Syverud K, Stenius P (2010) Emulsions stabilized by microfibrillated cellulose: the effect of hydrophobization, concentration and o/w ratio. J Dispers Sci Technol

Acknowledgments

This project was supported by the Research Council of Norway, Södra Cell, Akzo Nobel and Jotun. Dr. Leena-Sisko Johansson, Aalto University, Department of Forest Products and Technology, is thanked for the XPS analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xhanari, K., Syverud, K., Chinga-Carrasco, G. et al. Reduction of water wettability of nanofibrillated cellulose by adsorption of cationic surfactants. Cellulose 18, 257–270 (2011). https://doi.org/10.1007/s10570-010-9482-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-010-9482-y