Abstract

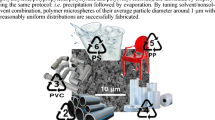

Polymer microspheres with uniform size, composition, and surface property have gained extensive researches in past decades. Conventional bottom-up approaches are using monomers or oligomers to build up desired polymer microspheres. However, directly sha** high-molecular-weight polymers into well-ordered polymer microspheres remains a great challenge. Herein, we reported a facile and efficient top-down approach to fabricate microspheres with high-molecular-weight polymer microfibers. By harnessing interfacial engineering-control during the polymer microspheres formation, uniformly sized microspheres could be produced with widely ranged diameters (from 10 µm to the capillary length of each polymer melt). The size limitation of this approach could be further extended by a controllable Plateau-Rayleigh instability phenomenon. Principally, the top-down approach allows fabrication of microspheres by various polymer melts with surface energy higher than 25 mN/m. Our work paves a way for green, cost-effective, and customizable production of a variety of functional polymer microspheres without any chemical reaction assistant.

Similar content being viewed by others

References

Tibbitt, M. W.; Dahlman, J. E.; Langer, R. Emerging frontiers in drug delivery. J. Am. Chem. Soc.2016, 138, 704–717.

Hossain, K. M. Z.; Patel, U.; Ahmed, I. Development of microspheres for biomedical applications: a review. Prog. Biomater.2015, 4, 1–19.

Yang, F.; Niu, X.; Gu, X.; Xu, C.; Wang, W.; Fan, Y. Biodegradable magnesium-incorporated poly(L-lactic acid) microspheres for manipulation of drug release and alleviation of inflammatory response. ACS Appl. Mater. Interfaces2019, 11, 23546–23557.

Salinas-Castillo, A.; Camprubi-Robles, M.; Mallavia, R. Synthesis of a new fluorescent conjugated polymer microsphere for chemical sensing in aqueous media. Chem. Commun.2010, 46, 1263–1265.

Wei, W.; Lu, R.; Tang, S.; Liu, X. Highly cross-linked fluorescent poly(cyclotriphosphazene-co-curcumin) microspheres for the selective detection of picric acid in solution phase. J. Mater. Chem. A2015, 3, 4604–4611.

Duan, J.; Liang, X.; Guo, J.; Zhu, K.; Zhang, L. Ultra-stretchable and force-sensitive hydrogels reinforced with chitosan microspheres embedded in polymer networks. Adv. Mater.2016, 28, 8037–8044.

Hou, J.; Ren, X.; Guan, S.; Duan, L.; Gao, G. H.; Kuai, Y.; Zhang, H. Rapidly recoverable, anti-fatigue, super-tough double-network hydrogels reinforced by macromolecular microspheres. Soft Matter2017, 13, 1357–1363.

Cheng, K.; Yang, M.; Zhang, R.; Qin, C.; Su, X.; Cheng, Z. Hybrid nanotrimers for dual T1, and T2-weighted magnetic resonance imaging. ACS Nano2014, 8, 9884–9896.

Zhang, X.; Cao, Y.; Jiang, Q.; Zhang, Y.; Yang, W. Preparation of cross-linked poly(methyl methacrylate) microspheres using an asymmetric cross-linker via dispersion polymerization and its application in light diffusers. Colloid Polym. Sci.2020, 1–10.

Kawaguchi, H. Functional polymer microspheres. Prog. Polym. Sci.2000, 25, 1171–1210.

Wichaita, W.; Polpanich, D.; Tangboriboonrat, P. Review on synthesis of colloidal hollow particles and their applications. Ind. Eng. Chem. Res.2019, 58, 20880–20901.

Liang, F.; Zhang, C.; Yang, Z. Rational design and synthesis of Janus composites. Adv. Mater.2014, 26, 6944–6949.

Zhang, Y.; Cattrall, R. W.; Kolev, S. D. Fast and environmentally friendly microfluidic technique for the fabrication of polymer microspheres. Langmuir2017, 33, 14691–14698.

Wooh, S.; Huesmann, H.; Tahir, M. N.; Paven, M.; Wichmann, K.; Vollmer, D.; Tremel, W.; Papadopoulos, P.; Butt, H. J. Synthesis of mesoporous supraparticles on superamphiphobic surfaces. Adv. Mater.2015, 27, 7338–7343.

Zhan, K.; Hou, X. Tunable microscale porous systems with dynamic liquid interfaces. Small2018, 14, 1703283.

Han, H.; Lee, J. S.; Kim, H.; Shin, S.; Lee, J.; Kim, J.; Hou, X.; Cho, S.W.; Seo, J.; Lee, T. Single-droplet multiplex bioassay on a robust and stretchable extreme wetting substrate through vacuum-based droplet manipulation. ACS Nano2018, 12, 932–941.

Min, L.; Zhang, H.; Pan, H.; Wu, F.; Hu, Y.; Sheng, Z.; Wang, M.; Zhang, M.; Wang, S.; Chen, X. Controllable liquid-liquid printing with defect-free, corrosion-resistance, unrestricted wetting condition. iScience2019, 19, 93–100.

El-Ballouli, A. O.; Bakr, O. M.; Mohammed, O. F. Compositional, processing, and interfacial engineering of nanocrystal- and quantum-dot-based perovskite solar cells. Chem. Mater.2019, 31, 6387–6411.

Wang, S.; Yang, X.; Wu, F.; Min, L.; Chen, X.; Hou, X. Inner surface design of functional microchannels for microscale flow control. Small2020, 16, 1905318.

Ju, J.; Yao, X.; Hou, X.; Liu, Q.; Zhang, Y. S.; Khademhosseini, A. A highly stretchable and robust non-fluorinated superhydrophobic surface. J. Mater. Chem. A2017, 5, 16273–16280.

Cai, C.; Dauskardt, R. H. Nanoscale interfacial engineering for flexible barrier films. Nano Lett.2015, 15, 6751–6755.

Deng, X.; Paven, M.; Papadopoulos, P.; Ye, M.; Wu, S.; Schuster, T.; Klapper, M.; Vollmer, D.; Butt, H. J. Solvent-free synthesis of microparticles on superamphiphobic surfaces. Angew. Chem. Int. Ed.2013, 52, 11286–11289.

Kaufman, J. J.; Tao, G.; Shabahang, S.; Banaei, E. H.; Deng, D. S.; Liang, X.; Johnson, S. G.; Fink, Y.; Abouraddy, A. F. Structured spheres generated by an in-fibre fluid instability. Nature2012, 487, 463–467.

Kaufman, J. J.; Ottman, R.; Tao, G.; Shabahang, S.; Banaei, E. H.; Liang, X.; Johnson, S. G.; Fink, Y.; Chakrabarti, R.; Abouraddy, A. F. In-fiber production of polymeric particles for biosensing and encapsulation. Proc. Natl. Acad. Sci. USA2013, 110, 15549–15554.

Kuo, T. Y.; Tseng, H. F.; Chiu, Y. J.; Chen, J. T. Morphology transformations of electrospun polymer fibers annealed on polymer films with thickness-controlled growth rates of undulation. Polymer2018, 134, 181–186.

Du, M.; Ye, S.; Tang, J.; Lv, S.; Chen, J.; Orava, J.; Tao, G.; Lan, P.; Hao, J.; Yang, Z.; Qiu, J.; Zhou, S. Scalable in-fiber manufacture of functional composite particles. ACS Nano2018, 12, 11130–11138.

Deng, X.; Mammen, L.; Butt, H. J.; Vollmer, D. Candle soot as a template for a transparent robust superamphiphobic coating. Science2012, 335, 67–70.

Schlaich, C.; Fan, Y.; Dey, P.; Cui, J.; Wei, Q.; Haag, R.; Deng, X. Universal, surfactant-free preparation of hydrogel beads on superamphiphobic and slippery surfaces. Adv. Mater. Interfaces2018, 5, 1701536.

Li, X.; Wang, D.; Tan, Y.; Yang, J.; Deng, X. Designing transparent micro/nano re-entrant-coordinated superamphiphobic surfaces with ultralow solid/liquid adhesion. ACS Appl. Mater. Interfaces2019, 11, 29458–29465.

Du, X. Y.; Li, Q.; Wu, G.; Chen, S. Multifunctional micro/nanoscale fibers based on microfluidic spinning technology. Adv. Mater.2019, 31, 1903733.

Xu, L. L.; Wang, C. F.; Chen, S. Microarrays formed by microfluidic spinning as multidimensional microreactors. Angew. Chem. Int. Ed.2014, 53, 3988–3992.

Zhang, Y.; Wang, C. F.; Chen, L.; Chen, S.; Ryan, A. J. Microfluidic-spinning-directed microreactors toward generation of multiple nanocrystals loaded anisotropic fluorescent microfibers. Adv. Funct. Mater.2015, 25, 7253–7262.

Yu, B.; Xue, T.; Pang, L.; Zhang, X.; Shen, Y.; Cong, H. The effect of different porogens on porous PMMA microspheres by seed swelling polymerization and its application in high-performance liquid chromatography. Materials2018, 11, 705.

Bux, J.; Manga, M. S.; Hunter, T. N.; Biggs, S. Manufacture of poly(methyl methacrylate) microspheres using membrane emulsification. Philos. T. R. Soc. A2016, 374, 20150134.

Papadopoulos, P.; Vollmer, D.; Butt, H. J. Long-term repellency of liquids by superoleophobic surfaces. Phys. Rev. Lett.2016, 117, 046102.

Zhao, B.; Wang, X.; Zhang, K.; Chen, L.; Deng, X. Impact of viscous droplets on superamphiphobic surfaces. Langmuir2016, 333, 144–151.

Williams, M. L.; Landel, R. F.; Ferry, J. D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc.1955, 77, 3701–3707.

Shereshefsky, J. Surface tension of saturated vapors and the equation of Eötvös. J. Phys. Chem.2002, 35, 1712–1720.

Rayleigh, L. XVI. On the instability of a cylinder of viscous liquid under capillary force. Philos. Mag.1892, 34, 145–154.

Young, T. III. An essay on the cohesion of fluids. Philos. Trans. R. Soc. London1805, 95, 65–87.

Laplace, P. S. Traité de mécanique céleste. de l’Imprimerie de Crapelet: 1799; Vol. 1.

Tomotika, S. On the instability of a cylindrical thread of a viscous liquid surrounded by another viscous fluid. Proc. R. Soc. London, Ser. A1935, 150, 322–337.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 21603026) and Sichuan Science and Technology Program (No. 2018RZ0115).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Electronic Supplementary Information

Electronic supplementary information (ESI) is available free of charge in the online version of this article.

Rights and permissions

About this article

Cite this article

Fan, Y., Wang, DH., Yang, JL. et al. Top-down Approach for Fabrication of Polymer Microspheres by Interfacial Engineering. Chin J Polym Sci 38, 1286–1293 (2020). https://doi.org/10.1007/s10118-020-2453-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2453-3