Abstract

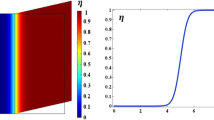

In this paper, the interaction of martensitic phase transformations (PTs) with vacancy evolution is studied using the phase field approach. The evolution of nanovacancies and martensite is captured by solving the Cahn–Hilliard and Ginzburg–Landau equations, respectively, coupled with elasticity equations. The Helmholtz free energy is considered as the combination of the terms belonging to the evolution of nanovacancies and those of the PT. The phase dependence of mixing energy, the nanovacancy concentration dependence of elastic properties, and the presence of transformation and misfit strain tensors in the constitutive equation are the important features of the interaction model. The finite element approach and the COMSOL code are used to solve the coupled system of equations. The thermally induced phase-vacancy interaction is studied for both the periodic boundary conditions (PBCs) and non-PBCs. A linear relation between the threshold misfit strain for the martensitic growth and temperature is found for both cases. The significant effect of the boundary periodicity on the elastic accommodation is discussed. The PT continuation/suppression is explained based on the thermodynamic equilibrium criterion. The effect of initial nanovacancy radius on the threshold misfit strain and the thermal driving force is investigated which is found temperature dependent and very different for the PBCs and non-PBCs. The threshold misfit strain for any temperature and the threshold thermal driving force for any radius are larger for the non-PBCs than those for the PBCs. They are almost the same for all the radii for the PBCs while they reduce as the radius increases for the non-PBCs. The coupled phase and vacancy evolution from an initially randomly distributed vacancy concentration is also analyzed which pronounces the key role of the vacancy initial conditions on the nanostructure. The proposed model and the obtained results help for a better understanding of the interaction of phase with vacancy and other various defects at the nanoscale.

Similar content being viewed by others

References

Bringa, E.M., Traiviratana, S., Meyers, M.A.: Void initiation in FCC metals: effect of loading orientation and nanocrystalline effects. Acta Mater. 58, 4458–4477 (2010). https://doi.org/10.1016/j.actamat.2010.04.043

Hooda, S., Avchachov, K., Khan, S.A., Djurabekova, F., Nordlund, K., Satpati, B., Bernstorff, S., Ahlawat, S., Kanjilal, D., Kabiraj, D.: Mechanistic details of the formation and growth of nanoscale voids in Ge under extreme conditions within an ion track. J. Phys. D. Appl. Phys. 50, 225302 (2017). https://doi.org/10.1088/1361-6463/aa6e25

Tang, T., Kim, S., Horstemeyer, M.F.: Molecular dynamics simulations of void growth and coalescence in single crystal magnesium. Acta Mater. 58, 4742–4759 (2010). https://doi.org/10.1016/j.actamat.2010.05.011

Zhang, N., Asle Zaeem, M.: Nanoscale self-healing mechanisms in shape memory ceramics. NPJ Comput. Mater. 5, 54 (2019). https://doi.org/10.1038/s41524-019-0194-z

Zhao, Y., Fang, Q., Liu, Y., Zeng, X.: Dislocation emission from nanovoid with the effect of neighboring nanovoids and surface stresses. Int. J. Solids Struct. 51, 1617–1629 (2014). https://doi.org/10.1016/j.ijsolstr.2014.01.014

Nomura, K., Chen, Y.-C., Weiqiang, W., Kalia, R.K., Nakano, A., Vashishta, P., Yang, L.H.: Interaction and coalescence of nanovoids and dynamic fracture in silica glass: multimillion-to-billion atom molecular dynamics simulations. J. Phys. D. Appl. Phys. 42, 214011 (2009). https://doi.org/10.1088/0022-3727/42/21/214011

Javanbakht, M., Sadegh Ghaedi, M.: Thermal induced nanovoid evolution in the vicinity of an immobile austenite-martensite interface. Comput. Mater. Sci. 172, 109339 (2020). https://doi.org/10.1016/j.commatsci.2019.109339

Alkhaldi, H.S., Kluth, P., Kremer, F., Lysevych, M., Li, L., Ridgway, M.C., Williams, J.S.: Void evolution and porosity under arsenic ion irradiation in GaAs 1–x Sb x alloys. J. Phys. D. Appl. Phys. 50, 125101 (2017). https://doi.org/10.1088/1361-6463/aa5a78

Lubarda, V., Schneider, M., Kalantar, D., Remington, B., Meyers, M.: Void growth by dislocation emission. Acta Mater. 52, 1397–1408 (2004). https://doi.org/10.1016/j.actamat.2003.11.022

**ong, L., Xu, S., McDowell, D.L., Chen, Y.: Concurrent atomistic–continuum simulations of dislocation–void interactions in fcc crystals. Int. J. Plast. 65, 33–42 (2015). https://doi.org/10.1016/j.ijplas.2014.08.002

Terentyev, D., Grammatikopoulos, P., Bacon, D.J., Osetsky, Y.N.: Simulation of the interaction between an edge dislocation and a 〈100〉 interstitial dislocation loop in α-iron. Acta Mater. 56, 5034–5046 (2008). https://doi.org/10.1016/j.actamat.2008.06.032

Yu, T., Shi, H.: Effects of grain size distribution on the creep damage evolution of polycrystalline materials. J. Phys. D. Appl. Phys. 43, 165401 (2010). https://doi.org/10.1088/0022-3727/43/16/165401

Asp, K., Ågren, J.: Phase-field simulation of sintering and related phenomena—a vacancy diffusion approach. Acta Mater. 54, 1241–1248 (2006). https://doi.org/10.1016/j.actamat.2005.11.005

Liu, N., Su, Y.: A comparative study of the phase-field approach in modeling the frequency-dependent characteristics of ferroelectric materials. Acta Mech. 227, 2671–2682 (2016). https://doi.org/10.1007/s00707-016-1638-x

Emmerich, H.: Advances of and by phase-field modelling in condensed-matter physics. Adv. Phys. 57, 1–87 (2008). https://doi.org/10.1080/00018730701822522

Henry, H., Levine, H.: Dynamic instabilities of fracture under biaxial strain using a phase field model. Phys. Rev. Lett. 93, 105504 (2004). https://doi.org/10.1103/PhysRevLett.93.105504

Chen, H.T., Soh, A.K., Ni, Y.: Phase field modeling of flexoelectric effects in ferroelectric epitaxial thin films. Acta Mech. 225, 1323–1333 (2014). https://doi.org/10.1007/s00707-013-1045-5

Steinbach, I.: Phase-field models in materials science. Model. Simul. Mater. Sci. Eng. 17, 073001 (2009). https://doi.org/10.1088/0965-0393/17/7/073001

Jacobs, A.E., Curnoe, S.H., Desai, R.C.: Simulations of cubic-tetragonal ferroelastics. Phys. Rev. B. 68, 224104 (2003). https://doi.org/10.1103/PhysRevB.68.224104

Levitas, V.I., Lee, D.-W., Preston, D.L.: Interface propagation and microstructure evolution in phase field models of stress-induced martensitic phase transformations. Int. J. Plast. 26, 395–422 (2010). https://doi.org/10.1016/j.ijplas.2009.08.003

Li, X., Su, Y.: A phase-field study of the martensitic detwinning in NiTi shape memory alloys under tension or compression. Acta Mech. 231, 1539–1557 (2020). https://doi.org/10.1007/s00707-020-02613-x

Mamivand, M., Zaeem, M.A., El Kadiri, H.: Phase field modeling of stress-induced tetragonal-to-monoclinic transformation in zirconia and its effect on transformation toughening. Acta Mater. 64, 208–219 (2014). https://doi.org/10.1016/j.actamat.2013.10.031

Seol, D.J., Hu, S.Y., Li, Y.L., Chen, L.Q., Oh, K.H.: Cubic to tetragonal martensitic transformation in a thin film elastically constrained by a substrate. Met. Mater. Int. 9, 221–226 (2003). https://doi.org/10.1007/BF03027039

Rasmussen, K.Ø., Lookman, T., Saxena, A., Bishop, A.R., Albers, R.C., Shenoy, S.R.: Three-dimensional elastic compatibility and varieties of twins in martensites. Phys. Rev. Lett. 87, 055704 (2001). https://doi.org/10.1103/PhysRevLett.87.055704

Chen, L.-Q.: Phase-field models for microstructure evolution. Annu. Rev. Mater. Res. 32, 113–140 (2002). https://doi.org/10.1146/annurev.matsci.32.112001.132041

Hu, S.Y., Li, Y.L., Zheng, Y.X., Chen, L.Q.: Effect of solutes on dislocation motion —a phase-field simulation. Int. J. Plast. 20, 403–425 (2004). https://doi.org/10.1016/S0749-6419(03)00094-9

Wang, Y.U., **, Y.M., Khachaturyan, A.G.: Phase field microelasticity modeling of dislocation dynamics near free surface and in heteroepitaxial thin films. Acta Mater. 51, 4209–4223 (2003). https://doi.org/10.1016/S1359-6454(03)00238-6

Rodney, D., Le Bouar, Y., Finel, A.: Phase field methods and dislocations. Acta Mater. 51, 17–30 (2003). https://doi.org/10.1016/S1359-6454(01)00379-2

Wang, Y., Li, J.: Phase field modeling of defects and deformation. Acta Mater. 58, 1212–1235 (2010). https://doi.org/10.1016/j.actamat.2009.10.041

Peng, X., et al.: A 3D phase field dislocation dynamics model for body-centered cubic crystals. Comp. Mater. Sci. 171, 109217 (2020). https://doi.org/10.1016/j.commatsci.2019.109217

Millett, P.C., Tonks, M.: Application of phase-field modeling to irradiation effects in materials. Curr. Opin. Solid State Mater. Sci. 15, 125–133 (2011). https://doi.org/10.1016/j.cossms.2010.10.002

Li, Y., Ma, D., Wang, B.: Influence of bulk free energy density on single void evolution based on the phase-field method. Comput. Mater. Sci. 163, 100–107 (2019). https://doi.org/10.1016/j.commatsci.2019.03.014

Yu, H.-C., Lu, W.: Dynamics of the self-assembly of nanovoids and nanobubbles in solids. Acta Mater. 53, 1799–1807 (2005). https://doi.org/10.1016/j.actamat.2004.12.029

Dsouza, S.M., Hirshikesh, T.V.M., et al.: A non-intrusive stochastic phase field method for crack propagation in functionally graded materials. Acta Mech. (2021). https://doi.org/10.1007/s00707-021-02956-z

Borzabadi Farahani, E., Sobhani Aragh, B., Voges, J., Juhre, D.: On the crack onset and growth in martensitic micro-structures; a phase-field approach. Int. J. Mech. Sci. 194, 106187 (2021). https://doi.org/10.1016/j.ijmecsci.2020.106187

Jafarzadeh, H., Mansoori, H.: Phase field approach to mode-I fracture by introducing an eigen strain tensor: general theory. Theor. Appl. Fract. Mech. 108, 102628 (2020). https://doi.org/10.1016/j.tafmec.2020.102628

Jafarzadeh, H., Levitas, V.I., Farrahi, G.H., Javanbakht, M.: Phase field approach for nanoscale interactions between crack propagation and phase transformation. Nanoscale 11, 22243–22247 (2019). https://doi.org/10.1039/C9NR05960A

Levin, V.A., et al.: Phase-field simulation of stress-induced martensitic phase transformations at large strains. Int. J. Solids. Struct. 50(19), 2914–2928 (2013). https://doi.org/10.1016/j.ijsolstr.2013.05.003

Levitas, V.I., Javanbakht, M.: Surface tension and energy in multivariant martensitic transformations: phase-field theory, simulations, and model of coherent interface. Phys. Rev. Lett. 105, 165701 (2010). https://doi.org/10.1103/PhysRevLett.105.165701

Li, C., et al.: Non-compact oxide-island growth induced by surface phase transition of the intermetallic NiAl during vacuum annealing. Acta Mater. 201, 244–253 (2020)

Schoof, E., Schneider, D., Streichhan, N., Mittnacht, T., Selzer, M., Nestler, B.: Multiphase-field modeling of martensitic phase transformation in a dual-phase microstructure. Int. J. Solids Struct. 134, 181–194 (2018). https://doi.org/10.1016/j.ijsolstr.2017.10.032

Segawa, M., Yamanaka, A., Nomoto, S.: Multi-phase-field simulation of cyclic phase transformation in Fe–C–Mn and Fe–C–Mn–Si alloys. Comput. Mater. Sci. 136, 67–75 (2017). https://doi.org/10.1016/j.commatsci.2017.04.014

**e, X., Kang, G., Kan, Q., Yu, C., Peng, Q.: Phase field modeling for cyclic phase transition of NiTi shape memory alloy single crystal with super-elasticity. Comp. Mater. Sci. 143, 212–224 (2018). https://doi.org/10.1016/j.commatsci.2017.11.017

Xu, B., Kang, G., Kan, Q., **e, C.Y., Peng, Q.: Phase field simulation to one-way shape memory effect of NiTi shape memory alloy single crystal. Comp. Mater. Sci. 161, 276–292 (2019). https://doi.org/10.1016/j.commatsci.2019.02.009

Xu, B., Kang, G., Kan, Q., Yu, C., **e, X.: Phase field simulation on the cyclic degeneration of one-way shape memory effect of NiTi shape memory alloy single crystal. Int. J. Mech. Sci. 168, 105303 (2020). https://doi.org/10.1016/j.ijmecsci.2019.105303

**, S., Su, Y.: Phase field study of the microstructural dynamic evolution and mechanical response of NiTi shape memory alloy under mechanical loading. Materials 14(1), 183 (2021). https://doi.org/10.3390/ma14010183

Xu, B., Kang, G.: Phase field simulation on the super-elasticity, elastocaloric and shape memory effect of geometrically graded nano-polycrystalline NiTi shape memory alloys. Int. J. Mech. Sci. 201, 106462 (2021). https://doi.org/10.1016/j.ijmecsci.2021.106462

Cissé, C., Asle Zaeem, M.: An asymmetric elasto-plastic phase-field model for shape memory effect, pseudoelasticity and thermomechanical training in polycrystalline shape memory alloys. Acta Mater. 201, 580–595 (2020). https://doi.org/10.1016/j.actamat.2020.10.034

Babaei, H., Levitas, V.I.: Effect of 60° dislocation on transformation stresses, nucleation, and growth for phase transformations between silicon I and silicon II under triaxial loading: phase-field study. Acta Mater. 177, 178–186 (2019). https://doi.org/10.1016/j.actamat.2019.07.021

Javanbakht, M., Levitas, V.I.: Phase field simulations of plastic strain-induced phase transformations under high pressure and large shear. Phys. Rev. B. 94, 214104 (2016). https://doi.org/10.1103/PhysRevB.94.214104

Javanbakht, M., Ghaedi, M.S., Barchiesi, E., Ciallella, A.: The effect of a pre-existing nanovoid on martensite formation and interface propagation: a phase field study. Math. Mech. Solids (2020). https://doi.org/10.1177/1081286520948118

Javanbakht, M., Ghaedi, M.S.: Nanovoid induced martensitic growth under uniaxial stress: effect of misfit strain, temperature and nanovoid size on PT threshold stress and nanostructure in NiAl. Comput. Mater. Sci 184, 109928 (2020). https://doi.org/10.1016/j.commatsci.2020.109928

Javanbakht, M., Ghaedi, M.S.: Nanovoid induced multivariant martensitic growth under negative pressure: effect of misfit strain and temperature on PT threshold stress and phase evolution. Mech. Mater. (2020). https://doi.org/10.1016/j.mechmat.2020.103627

Mamivand, M., Zaeem, M.A., El Kadiri, H.: A review on phase field modeling of martensitic phase transformation. Comput. Mater. Sci. 77, 304–311 (2013). https://doi.org/10.1016/j.commatsci.2013.04.059

Hu, S., Henager, C.H.: Phase-field modeling of void lattice formation under irradiation. J. Nucl. Mater. 394, 155–159 (2009). https://doi.org/10.1016/j.jnucmat.2009.09.002

Hu, S.Y., Henager, C.H.: Phase-field simulation of void migration in a temperature gradient. Acta Mater. 58, 3230–3237 (2010). https://doi.org/10.1016/j.actamat.2010.01.043

Rokkam, S., El-Azab, A., Millett, P., Wolf, D.: Phase field modeling of void nucleation and growth in irradiated metals. Model. Simul. Mater. Sci. Eng. 17, 064002 (2009). https://doi.org/10.1088/0965-0393/17/6/064002

Millett, P.C., El-Azab, A., Rokkam, S., Tonks, M., Wolf, D.: Phase-field simulation of irradiated metals: Part I: void kinetics. Comput. Mater. Sci. 50, 949–959 (2011). https://doi.org/10.1016/j.commatsci.2010.10.034

Millett, P.C., El-Azab, A., Wolf, D.: Phase-field simulation of irradiated metals: Part II: gas bubble kinetics. Comput. Mater. Sci. 50, 960–970 (2011). https://doi.org/10.1016/j.commatsci.2010.10.032

Li, Y., Hu, S., Sun, X., Gao, F., Henager, C.H., Khaleel, M.: Phase-field modeling of void migration and growth kinetics in materials under irradiation and temperature field. J. Nucl. Mater. 407, 119–125 (2010). https://doi.org/10.1016/j.jnucmat.2010.09.048

Li, Y., Hu, S., Montgomery, R., Gao, F., Sun, X.: Phase-field simulations of intragranular fission gas bubble evolution in UO2 under post-irradiation thermal annealing. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 303, 62–67 (2013). https://doi.org/10.1016/j.nimb.2012.11.028

Vance, I.W., Millett, P.C.: Phase-field simulations of pore migration and morphology change in thermal gradients. J. Nucl. Mater. 490, 299–304 (2017). https://doi.org/10.1016/j.jnucmat.2017.04.027

Javanbakht, M., Ghaedi, M.S.: Phase field approach for void dynamics with interface stresses at the nanoscale. Int. J. Eng. Sci. 154, 103279 (2020). https://doi.org/10.1016/j.ijengsci.2020.103279

Li, Y., Hu, S., Sun, X., Stan, M.: A review: applications of the phase field method in predicting microstructure and property evolution of irradiated nuclear materials. Npj. Comp. Mater. (2017). https://doi.org/10.1038/s41524-017-0018-y

Das, A.: Martensite–void interaction. Scripta Mater. 68(7), 514–517 (2013). https://doi.org/10.1016/j.scriptamat.2012.11.039

Feng, R., et al.: Micromechanism of cold deformation of two-phase polycrystalline Ti–Al alloy with void. Materials 12(1), 184 (2019). https://doi.org/10.3390/ma12010184

Isik, K., et al.: Evaluation of void nucleation and development during plastic deformation of dual-phase steel DP600. Steel. Res. Int. 87(12), 1583–1591 (2016). https://doi.org/10.1002/srin.201500483

Yan, G.: Phase retransformation and void evolution of previously heated HMX-based plastic-bonded explosive in wet air. J. Phys. Chem. C. 121(37), 20426–20432 (2017). https://doi.org/10.1021/acs.jpcc.7b04165

Stubbins, J.F.: Void swelling and radiation-induced phase transformation in high purity Fe–Ni–Cr alloys. J. Nuc. Mater. 141–143(2), 748–753 (1986). https://doi.org/10.1016/0022-3115(86)90085-1

Mazey, D.J., Harries, D.R., Hudson, J.A.: The effects of silicon and titanium on void swelling and phase stability in 12Cr–15Ni austenitic alloys irradiated with 46 MeV nickel ions. J. Nucl. Mater. 89(1), 155–181 (1980). https://doi.org/10.1016/0022-3115(80)90020-3

Porter, D., Garner, F.G.: Bond, interaction of void-induced phase instability and subsequent void growth in AISI 304 stainless steel. In: Hamilton, M., Kumar, A., Rosinski, S., Grossbeck, M (eds.) Effects of Radiation on Materials: 19th International Symposium, pp. 884–893. ASTM International, West Conshohocken, PA (2000). https://doi.org/10.1520/STP12439S

Meister, S., et al.: Void formation induced electrical switching in phase-change nanowires. Nano Lett. 8(12), 4562–4567 (2008). https://doi.org/10.1021/nl802808f

Park, S.J.: Structural deformation and void formation driven by phase transformation in the Ge2Sb2Te5 film. J. Mater. Chem. C 2, 2001–2009 (2014). https://doi.org/10.1039/C3TC31924E

Jiang, Y.: Phase-field simulation of the interaction between intergranular voids and grain boundaries during radiation in UO2. Comp. Mater. Sci. 188, 110176 (2021). https://doi.org/10.1016/j.commatsci.2020.110176

Basak, A., Levitas, V.I.: Phase field study of surface-induced melting and solidification from a nanovoid: effect of dimensionless width of void surface and void size. Appl. Phys. Lett. 112, 201602 (2018). https://doi.org/10.1063/1.5029911

Babaei, H., Levitas, V.I.: Phase field approach for stress- and temperature-induced phase transformations that satisfies lattice instability conditions. Part 2 Simulations of phase transformations Si I–Si II. Int. J. Plast. 107, 223–245 (2018). https://doi.org/10.1016/j.ijplas.2018.03.007

Yue, B., et al.: A simple variant selection in stress-driven martensitic transformation. Proc. Natl. Acad. Sci. 116(30), 14905–14909 (2019). https://doi.org/10.1073/pnas.1906365116

Pattor, E., et al.: Shape memory alloys, part I: general properties and modeling of single crystals. Mech. Mater. 38(5–6), 391–429 (2006). https://doi.org/10.1016/j.mechmat.2005.05.027

Lovey, F.C., et al.: Interaction of single variant martensitic transformation with small γ type precipitates in CuZnAl. Acta Metall. Mater. 42(2), 453–460 (1994). https://doi.org/10.1016/0956-7151(94)90500-2

Hamilton, R.F.: Transformation of Co–Ni–Al single crystals in tension. Script. Mater. 53(1), 131–136 (2005). https://doi.org/10.1016/j.scriptamat.2005.01.032

Gao, Y., Zhang, Y., Schwen, D., Jiang, C., Sun, C., Gan, J.: Formation and self-organization of void superlattices under irradiation: a phase field study. Materialia. 1, 78–88 (2018). https://doi.org/10.1016/j.mtla.2018.04.003

Levitas, V.I., Preston, D.L., Lee, D.-W.: Three-dimensional Landau theory for multivariant stress-induced martensitic phase transformations. III. Alternative potentials, critical nuclei, kink solutions, and dislocation theory. Phys. Rev. B. 68, 134201 (2003). https://doi.org/10.1103/PhysRevB.68.134201

Gao, Y., et al.: Formation and self-organization of void superlattices under irradiation: a phase field study. Materialia. 1, 78–88 (2018). https://doi.org/10.1016/j.mtla.2018.04.003

Gao, Y., Zhang, Y., Schwen, D., Jiang, C., Sun, C., Gan, J., Bai, X.-M.: Theoretical prediction and atomic kinetic Monte Carlo simulations of void superlattice self-organization under irradiation. Sci. Rep. 8, 6629 (2018). https://doi.org/10.1038/s41598-018-24754-9

Chen, G.-X., Zhang, J.-M., Xu, K.-W.: Self-diffusion of Ni in B2 type intermetallic compound NiAl. J. Alloys Compd. 430, 102–106 (2007). https://doi.org/10.1016/j.jallcom.2006.04.052

Yang, M., Wei, H., Zhang, J., Zhao, Y., **, T., Liu, L., Sun, X.F.: Phase-field study on effects of antiphase domain and elastic energy on evolution of γ′ precipitates in nickel-based superalloys. Comput. Mater. Sci. 129, 211–219 (2017). https://doi.org/10.1016/j.commatsci.2016.11.036

Levitas, V.I., Preston, D.L.: Three-dimensional Landau theory for multivariant stress-induced martensitic phase transformations. I. Austenite—martensite. Phys. Rev. B. 66, 134206 (2002). https://doi.org/10.1103/PhysRevB.66.134206

Li, Y.L., Cai, J., Mo, D.: Molecular dynamics simulations on the effect of nanovoid on shock-induced phase transition in uranium nitride. Phys. Lett. A. 383, 458–463 (2019). https://doi.org/10.1016/j.physleta.2018.11.017

He, A.M., Duan, S., Shao, J.-L., Wang, P., Qin, C.: Shock melting of single crystal copper with a nanovoid: molecular dynamics simulations. J. Appl. Phys. 112, 074116 (2012). https://doi.org/10.1063/1.4757949

Shao, J.L., Duan, S.Q., He, A.M., Wang, P., Qin, C.S.: Microscopic dynamics of structural transition in iron with a nanovoid under shock loading. J. Phys. Condens. Matter. 22, 355403 (2010). https://doi.org/10.1088/0953-8984/22/35/355403

Cui, X., Zhu, W., He, H., Deng, X., Li, Y.: Phase transformation of iron under shock compression: effects of voids and shear stress. Phys. Rev. B. 78, 024115 (2008). https://doi.org/10.1103/PhysRevB.78.024115

Zhao, K., Gudem Ringdalen, I., Wu, J., He, J., Zhang, Z.: Ductile mechanisms of metals containing pre-existing nanovoids. Comput. Mater. Sci. 125, 36–50 (2016). https://doi.org/10.1016/j.commatsci.2016.08.027

Lu, W., Suo, Z.: Symmetry breaking in self-assembled monolayers on solid surfaces: anisotropic surface stress. Phys. Rev. B. 65, 085401 (2002). https://doi.org/10.1103/PhysRevB.65.085401

Li, S., Sellers, S.S., Basaran, C., Schultz, A.J., Kofke, D.A.: Lattice strain due to an atomic vacancy. Int. J. Mol. Sci. 10(6), 2798–2808 (2009). https://doi.org/10.3390/ijms10062798

Kotzurek, J.A., Steyskal, E.M., Oberorfer, B., Hohenwarter, A., Pippan, R., Sprengel, W., Wurschum, R.: Direct measurement of vacancy relaxation by dilatometry. Appl. Phys. Lett. 109, 021906 (2016). https://doi.org/10.1063/1.4958895

Zhu, B., Huang, M., Li, Z.: Brittle to ductile transition of metallic glasses induced by embedding spherical nanovoids. J. Appl. Phys. 122, 215108 (2017). https://doi.org/10.1063/1.4997281

Bai, X.-M., Li, M.: Nucleation and melting from nanovoids. Nano Lett. 6, 2284–2289 (2006). https://doi.org/10.1021/nl0617282

Xu, S., Su, Y.: Nanovoid growth in BCC α-Fe: influences of initial void geometry. Model. Simul. Mater. Sci. Eng. 24, 085015 (2016). https://doi.org/10.1088/0965-0393/24/8/085015

Acknowledgements

The support of Isfahan University of Technology and Iran National Science Foundation is gratefully acknowledged.

Author information

Authors and Affiliations

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Javanbakht, M., Ghaedi, M.S. Interaction of martensitic transformations and vacancy diffusion at the nanoscale under thermal loading: a phase field model and simulations. Acta Mech 232, 4567–4582 (2021). https://doi.org/10.1007/s00707-021-03067-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-03067-5