Abstract

Optimization can apply in almost every branch of science and technology. In particular, a gradient-based iterative method is a mathematical optimization procedure that can be used to make decisions. The gradient-based optimization method can only find a local minimum of the objective function if the algorithm starts with the appropriate initial data. The ambition of this article is to develop a new scheme to make an initial guess for iterative optimization methods to calibrate accurately the material parameters of strain-hardening elastoplastic constitutive models based on the test data. The elastoplastic models are Drucker–Prager and modified Cam-Clay, and the data obtained from triaxial, oedometric, and hydrostatic tests. The validity of proposed material parameters is evaluated using a home-made finite-element simulator. The results emphasize the ability of the proposed procedure to accurately calibrate material parameters.

Similar content being viewed by others

References

Aydan Ö (2019) Rock mechanics and rock engineering. CRC Press, London

Bazaraa (2006) Nonlinear programming: theory and algorithms, 3rd edition. Wiley, New York

Callari C, Auricchio F, Sacco E (1998) A finite-strain cam-clay model in the framework of multiplicative elasto-plasticity. Int J Plast 14(12):1155–1187

Cekerevac C, Girardin S, Klubertanz G, Laloui L (2006) Calibration of an elasto-plastic constitutive model by a constrained optimisation procedure. Comput Geotech 33(8):432–443

Chong EK, Zak SH (2001) An Introduction to Optimization. Wiley, New York

de Souza Neto EA, Peri D, Owen DRJ (2008) Computational methods for plasticity. Wiley, New York

Devloo PRB (1997) PZ: an object oriented environment for scientific programming. Comput Methods Appl Mech Eng 150(1–4):133–153

Devloo PRB (2000) Object oriented tools for scientific computing. Eng Comput 16(1):63–72

Doherty J, Alguire H, Wood DM (2012) Evaluating modified cam clay parameters from undrained triaxial compression data using targeted optimization. Can Geotech J 49(11):1285–1292

Drucker DC, Prager W (1952) Soil mechanics and plastic analysis or limit design. Q Appl Math 10(2):157–165

Feng Y, Zamani K, Yang H, Wang H, Wang F, Jeremić B (2019) Procedures to build trust in nonlinear elastoplastic integration algorithm: solution and code verification. Eng Comput 36(4):1643–1656

Ferreira D (2019) DIANA finite element analysis, userś manual, version 10.3. DIANA, Delft

Ghaboussi J, Garrett JH, Wu X (1991) Knowledge-based modeling of material behavior with neural networks. J Eng Mech 117(1):132–153

Graham J (2006) The 2003 R.M. Hardy lecture: soil parameters for numerical analysis in clay. Can Geotech J 43(2):187–209

Han H, Yin S (2018) Determination of in-situ stress and geomechanical properties from borehole deformation. Energies 11(1):131

Ichikawa Y, Ito T, Mroz Z (1990) A strain localization condition applying multi-response theory. Ing-Arch 60:542–552

Karakus M, Fowell R (2005) Back analysis for tunnelling induced ground movements and stress redistribution. Tunnel Undergr Space Technol 20(6):514–524

Kowalska M (2007) Calibration of modified cam clay model with use of loading path method and genetic algorithms. In: 18th European young geotechnical engineers’ conference held in Ancona, Italy

Krabbenhoft K, Lyamin A (2012) Computational cam clay plasticity using second-order cone programming. Comput Methods Appl Mech Eng 209–212:239–249

Li M, Cao Y, Shen W, Shao J (2017) A damage model of mechanical behavior of porous materials: application to sandstone. Int J Damage Mech 27(9):1325–1351

Macari EJ, Samarajiva P, Wathugala W (2005) Selection and calibration of soil constitutive model parameters using genetic algorithms. In soil constitutive models. American Society of Civil Engineers, New York

Mattsson H, Klisinski M, Axelsson K (2001) Optimization routine for identification of model parameters in soil plasticity. Int J Numer Anal Methods Geomech 25(5):435–472

Moslemi N, Zardian MG, Ayob A, Redzuan N, Rhee S (2019) Evaluation of sensitivity and calibration of the Chaboche kinematic hardening model parameters for numerical ratcheting simulation. Appl Sci 9(12):2578

Navarro V, Candel M, Barenca A, Yustres A, García B (2007) Optimisation procedure for choosing cam clay parameters. Comput Geotech 34(6):524–531

Obrzud RF, Vulliet L, Truty A (2009) Optimization framework for calibration of constitutive models enhanced by neural networks. Int J Numer Anal Methods Geomech 33(1):71–94

Perić D (2006) Analytical solutions for a three-invariant cam clay model subjected to drained loading histories. Int J Numer Anal Methods Geomech 30(5):363–387

Qian J, Xu W, Mu L, Wu A (2020) Calibration of soil parameters based on intelligent algorithm using efficient sampling method. Undergr Space

Rios LM, Sahinidis NV (2012) Derivative-free optimization: a review of algorithms and comparison of software implementations. J Global Optim 56(3):1247–1293

Risnes R, Madland M, Hole M, Kwabiah N (2005) Water weakening of chalk-mechanical effects of water-glycol mixtures. J Petrol Sci Eng 48(1–2):21–36

Rocscience (2015) Rocscience users manual Inc., Toronto

Rudnicki JW (1986) Fluid mass sources and point forces in linear elastic diffusive solids. Mech Mater 5(4):383–393

Ryckelynck D, Benziane DM (2016) Hyper-reduction framework for model calibration in plasticity-induced fatigue. Adv Model Simul Eng Sci 3(1)

Sagrilo LVS, de Sousa JRM, Lima ECP, Porto EC, Fernandes JVV (2012) A study on the holding capacity safety factors for torpedo anchors. J Appl Math 2012:1–18

Sanei M, Durán O, Devloo PR, Santos ES (2020) An innovative procedure to improve integration algorithm for modified cam-clay plasticity model. Comput Geotech

Santos E, Ferreira F (2010) Mechanical behavior of a Brazilian off-shore carbonate reservoir. In: 44th U.S. rock mechanics symposium and 5th U.S.-Canada rock mechanics symposium, Salt Lake City

Seidl DT, Granzow BN (2020) Calibration of elastoplastic constitutive model parameters from full-field data with automatic differentiation-based sensitivities. Preprint

Shao J-F, **e S-Y (2013) Elastoplastic behavior of ductile porous rocks. In: Constitutive modeling of soils and rocks, pp 187–210. ISTE

Shao J, Jia Y, Kondo D, Chiarelli A (2006) A coupled elastoplastic damage model for semi-brittle materials and extension to unsaturated conditions. Mech Mater 38(3):218–232

Shen W, Shao J (2017) Some micromechanical models of elastoplastic behaviors of porous geomaterials. J Rock Mech Geotech Eng 9(1):1–17

Shuku T, Murakami A, Ichi Nishimura S, Fujisawa K, Nakamura K (2012) Parameter identification for cam-clay model in partial loading model tests using the particle filter. Soils Found 52(2):279–298

Systémes D (2012) Abaqus/standard userś manual, version 6.12. Simulia

**e S, Shao J (2006) Elastoplastic deformation of a porous rock and water interaction. Int J Plast 22(12):2195–2225

**e SY, Shao JF (2014) An experimental study and constitutive modeling of saturated porous rocks. Rock Mech Rock Eng 48(1):223–234

Zhang C-L (2016) The stress-strain-permeability behaviour of clay rock during damage and recompaction. J Rock Mech Geotech Eng 8(1):16–26

Acknowledgements

M. Sanei, P.R.B. Devloo, and O. Durán thankfully acknowledge financial support from ANP-Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP-PETROBRAS) (grant 2014/00090-2). P.R.B. Devloo also acknowledges financial support from FAPESP, Brazil—Fundação de Amparo á Pesquisa do Estado de São Paulo, Brazil (grant 2017/15736-3), and from CNPq - Conselho Nacional de Desenvolvimento Científico e Tecnológico (grant 310369/2006-1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

Development of Analytical Equations for \(\eta\) and \(\xi _\mathrm{c}\)

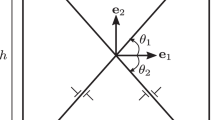

The analytical equations to compute the initial guess for parameters \(\eta\) and \(\xi _\mathrm{c}\) are developed. The proposed equations are obtained using experimental data that are at least two points. The points can be the extreme points, namely \(pt_{1}=\left\{ P_1,\sqrt{J_{2_1}}\right\}\) and \(pt_{2}=\left\{ P_2,\sqrt{J_{2_2}}\right\}\), where \(P_2>P_1\) (Fig. 20a). The analytical equations are derived as:

Then, the parameter \(\eta\) is estimated by:

The parameter \(\xi _\mathrm{c}\) is computed by:

Development of Analytical Equations for \(P^{\circ }\), \(p_\mathrm{t}\), and eC

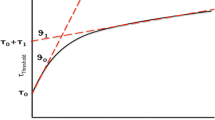

The analytical equations are developed to compute the initial guess for parameters \(P^{\circ }\), \(p_\mathrm{t}\), and eC. The proposed equations are obtained using hydrostatic test data that are at least three points. The points can be extremes and an intermediate point. The analytical equations are developed by considering \(p_{zt}=P^{\circ }+p_\mathrm{t}\), and taking the derivative of \(P_\mathrm{cc}=P\) with respect to \(\epsilon _\mathrm{ev}\), as:

The three selected points are called \(pt_{1}=\left\{ \epsilon _{\mathrm{ev}_{1}}, P_{1}\right\}\), \(pt_{2}=\left\{ \epsilon _{\mathrm{ev}_{2}},P_{2}\right\}\), and \(pt_{3}=\left\{ \epsilon _{\mathrm{ev}_{3}},P_{3}\right\}\), where \(\epsilon _{\mathrm{ev}_{3}}<\epsilon _{\mathrm{ev}_{2}}<\epsilon _{\mathrm{ev}_{1}}\) (Fig. 20b).

1.1 Estimation of eC

By taking two points pt\(_{z}\) and pt\(_{ w}\), the derivative \(P^{'}\) for each point is obtained as:

The parameter eC is computed by dividing \(P_{z}^{'}\) by \(P_{ w}^{'}\)

where

where the numbers 1, 2, 3 are indices of three hydrostatic points.

1.2 Estimation of \(p_{zt}\)

By taking two points pt\(_{z}\) and pt\(_{w}\), the P for each point is obtained as:

The parameter \(p_{zt}\) is gotten by subtracting \(P_{w}\) from \(P_{z}\), as:

By selecting any pairs of three points pt\(_{1}\), pt\(_{2}\), and pt\(_{3}\), the parameter \(p_{zt}\) can be computed using Eq. (81). Here, the parameter \(p_{zt}\) is obtained from two extreme points, as:

1.3 Estimation of \(p_\mathrm{t}\)

The parameter \(p_\mathrm{t}\) is estimated using the below expression

Then

Results of the Norm Error and the Quantities of Material Parameters

The results of the \(L_2\) norm error and the quantities of material parameters of nonlinear elasticity using different initial guesses, such as: \(\left( 0,0,0\right)\), \(\left( 0.5,0.5,0.5\right)\), \(\left( 1.0,1.0,1.0\right)\), and \(\left( 14.856,-0.566,6.157\right)\) are given in Tables 13, 14, 15, and 16.

Rights and permissions

About this article

Cite this article

Sanei, M., Devloo, P.R.B., Forti, T.L.D. et al. An Innovative Scheme to Make an Initial Guess for Iterative Optimization Methods to Calibrate Material Parameters of Strain-Hardening Elastoplastic Models. Rock Mech Rock Eng 55, 399–421 (2022). https://doi.org/10.1007/s00603-021-02665-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-021-02665-y