Abstract

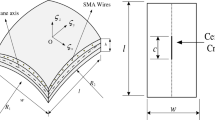

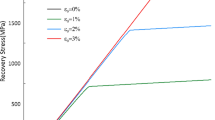

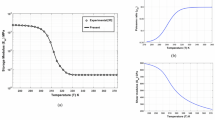

The thermal buckling load factors of damaged (crack) laminated composite structures have been investigated numerically first-hand. Their strength reversal due to the functional material reinforcement under the elevated environmental conditions is reported in detail. In this regard, a generic finite element model of the damaged layered structure has been derived in the higher-order kinematic model considering the Green–Lagrange type of strain (to count the large deformation due to temperature). Further, the shape memory alloy (SMA) fibre effect has been introduced in the proposed mathematical model via marching technique under the change in temperature to achieve the modified elastic property. The final governing equation of buckled structure has been derived and solved through isoparametric finite element steps. The final buckling temperatures of the damaged layered structural system with and without SMA (volume fraction and prestrain) fibres were obtained, and the results indicate a good improvement (maximum up to 37%). Additionally, the structural geometry-related parameters, including their shapes, have been changed to show the model's applicability.

Similar content being viewed by others

Abbreviations

- ΔT cr :

-

Critical buckling temperature

- ρ :

-

Density

- \(u_{{1\xi_{{\text{x}}} }}\) \(u_{{1\xi_{{\text{y}}} }}\) and \(u_{{1\xi_{{\text{z}}} }}\) :

-

Displacement at mid-plane

- \(\left\{ \lambda \right\},\left\{ {\dot{\lambda }} \right\}\) and \(\left\{ {\ddot{\lambda }} \right\}\) :

-

Displacement, velocity, and acceleration

- \(\left\{ \Delta \right\}\) :

-

Eigenvector

- \(\left\{ {\delta_{0} } \right\}\) and \(\left\{ {\delta_{{{\text{oi}}}} } \right\}\) :

-

Elemental and nodal displacement

- \([K_{{G_{{{\text{ther}}}} }} ]^{{{\text{elm}}}}\) and \([K_{{G_{{{\text{rec}}}} }} ]^{{{\text{elm}}}}\) :

-

Elemental geometric stiffness matrix of thermal and recovery stresses

- \(\theta\) :

-

Fibre orientation angle

- \(\{ \overline{\varepsilon }_{{\text{G}}} \}\) :

-

Geometric strain vector

- \(\left[ {K_{{\text{G}}} } \right]\) :

-

Geometrical stiffness matrix

- \(U_{{\xi {\text{x}}}}\), \(U_{{\xi {\text{y}}}}\) and \(U_{{\xi {\text{z}}}}\) :

-

Global displacement

- \(\xi_{{\text{x}}} ,\;\xi_{{\text{y}}}\) and \(\xi_{{\text{z}}}\) :

-

Global reference axis of the shell panel

- \(u_{{3\xi_{{\text{x}}} }}\) \(u_{{3\xi_{{\text{y}}} }}\) \(u_{{4\xi_{{\text{x}}} }}\) and \(u_{{4\xi_{{\text{y}}} }}\) :

-

Higher-order deformation parameters

- l, b, and h :

-

Length, width, and depth of laminated shell panel

- \(\left[ M \right]\) :

-

Mass matrix

- \(\left[ {D_{{G_{{{\text{rec}}}} }} } \right]\) and \(\left[ {D_{{G_{{{\text{ther}}}} }} } \right]\) :

-

Material property matrix w.r.t recovery and thermal load

- \(\left\{ {f_{{{\text{mech}}}} } \right\}\), \(\left\{ {f_{{{\text{ther}}}} } \right\}\) and \(\left\{ {f_{{{\text{rec}}}} } \right\}\) :

-

Mechanical load, thermal load, and the recovery load vector

- n l :

-

Number of layers in the composite

- v :

-

Poison’s ratio

- \(u_{{2\xi_{{\text{x}}} }}\) and \(u_{{2\xi_{{\text{y}}} }}\) :

-

Rotation along \(\xi_{{\text{x}}} ,\;\xi_{{\text{y}}}\)

- \(N\) :

-

Shape function

- G 11, G 12, G 23 :

-

Shear modulus

- \(\left[ K \right]\) :

-

Stiffness matrix

- \(\varepsilon\) and ε r :

-

Strain and prestrain

- \(\left[ B \right]\) and \(\left[ {B_{{\text{G}}} } \right]\) :

-

Strain displacement matrix

- \(\sigma_{{{\text{rec}}}}\) and \(\sigma_{{{\text{ther}}}}\) :

-

Stresses due to recovery and thermal load.

- \(\Delta T\) :

-

Temperature difference

- \(\alpha\) :

-

Thermal expansion coefficient

- \(\{ U\}\) :

-

Total strain energy

- \(\Delta W_{{{\text{tot}}}}\) :

-

Total work done

- \(V_{{f_{{{\text{SMA}}}} }}\)/V f :

-

Volume fraction of SMA

- E 11, E 12, E 23 :

-

Young’s modulus values

References

Thornton, E.A.: Thermal buckling of plates and shells. Appl. Mech. Rev. 46, 485–506 (1993). https://doi.org/10.1115/1.3120310

Chang, J.-S., Leu, S.-Y.: Thermal buckling analysis of antisymmetric angle-ply laminates based on a higher-order displacement field. Compos. Sci. Technol. 41, 109–128 (1991). https://doi.org/10.1016/0266-3538(91)90023-I

Chandrashekhara, K.: Thermal buckling of laminated plates using a shear flexible finite element. Finite Elem. Anal. Des. 12, 51–61 (1992). https://doi.org/10.1016/0168-874X(92)90006-X

Naghsh, A., Azhari, M., Saadatpour, M.M.: Thermal buckling analysis of point-supported laminated composite plates in unilateral contact. Appl. Math. Model. 56, 564–583 (2018). https://doi.org/10.1016/j.apm.2017.12.020

Lakshmi Narayana, A., Vijaya Kumar, R., Krishnamohana Rao, G.: Effect of volume fraction on the thermal buckling analysis of laminated composite plate with square/rectangular cutout. Mater. Today Proc. 5, 5819–5829 (2018). https://doi.org/10.1016/j.matpr.2017.12.179

Lakshmi Narayana, A., Vijaya Kumar, R., Krishnamohana Rao, G.: Thermal buckling analysis of laminated composite plate with square/rectangular. Elliptical/Circular Cutout. Mater. Today Proc. 5, 5354–5363 (2018). https://doi.org/10.1016/j.matpr.2017.12.121

Baseri, V., Jafari, G.S., Kolahchi, R.: Analytical solution for buckling of embedded laminated plates based on higher order shear deformation plate theory. Steel Compos. Struct. 21(4), 883–919 (2016). https://doi.org/10.12989/scs.2016.21.4.883

Akbaş, ŞD.: Post-buckling analysis of a fiber reinforced composite beam with crack. Eng. Fract. Mech. 212, 70–80 (2019). https://doi.org/10.1016/j.engfracmech.2019.03.007

Sadeghifar, M., Bagheri, M., Jafari, A.A.: Buckling analysis of stringer-stiffened laminated cylindrical shells with nonuniform eccentricity. Arch. Appl. Mech. 81, 875–886 (2011). https://doi.org/10.1007/s00419-010-0457-0

Shimamoto, A., Ohkawara, H., Nogata, F.: Enhancement of mechanical strength by shape memory effect in TiNi fiber-reinforced composites. Eng. Fract. Mech. 71, 737–746 (2004). https://doi.org/10.1016/S0013-7944(03)00052-3

Lee, H.J., Lee, J.J., Huh, J.S.: A simulation study on the thermal buckling behavior of laminated composite shells with embedded shape memory alloy (SMA) wires. Compos. Struct. 47, 463–469 (1999). https://doi.org/10.1016/S0263-8223(00)00020-9

Tawfik, M., Ro, J.J., Mei, C.: Thermal post-buckling and aeroelastic behaviour of shape memory alloy reinforced plates. Smart Mater. Struct. 11, 297–307 (2002). https://doi.org/10.1088/0964-1726/11/2/313

Park, J.-S., Kim, J.-H., Moon, S.-H.: Thermal post-buckling and flutter characteristics of composite plates embedded with shape memory alloy fibers. Compos. Part B Eng. 36, 627–636 (2005). https://doi.org/10.1016/j.compositesb.2004.11.007

Kumar, S.K., Singh, B.N.: Thermal buckling analysis of SMA fiber-reinforced composite plates using layerwise model. J. Aerosp. Eng. 22, 342–353 (2009). https://doi.org/10.1061/(ASCE)0893-1321(2009)22:4(342)

Kumar, C.N., Singh, B.N.: Thermal buckling and post-buckling of laminated composite plates with SMA fibers using layerwise theory. Int. J. Comput. Methods Eng. Sci. Mech. 10, 423–429 (2009). https://doi.org/10.1080/15502280903108024

Panda, S.K., Singh, B.N.: Thermal post-buckling analysis of a laminated composite spherical shell panel embedded with shape memory alloy fibres using non-linear finite element method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 224, 757–769 (2010). https://doi.org/10.1243/09544062JMES1809

Kamarian, S., Shakeri, M.: Thermal buckling analysis and stacking sequence optimization of rectangular and skew shape memory alloy hybrid composite plates. Compos. Part B Eng. 116, 137–152 (2017). https://doi.org/10.1016/j.compositesb.2017.01.059

Manickam, G., Bharath, A., Das, A.N., Chandra, A., Barua, P.: Thermal buckling behaviour of variable stiffness laminated composite plates. Mater. Today Commun. 16, 142–151 (2018). https://doi.org/10.1016/j.mtcomm.2018.05.003

Torabi, J., Ansari, R., Hassani, R.: Numerical study on the thermal buckling analysis of CNT-reinforced composite plates with different shapes based on the higher-order shear deformation theory. Eur. J. Mech. A/Solids. 73, 144–160 (2019). https://doi.org/10.1016/j.euromechsol.2018.07.009

Civalek, Ö., Dastjerdi, S., Akgöz, B.: Buckling and free vibrations of CNT-reinforced cross-ply laminated composite plates. Mech. Based Des. Struct. Mach. 50, 1914–1931 (2022). https://doi.org/10.1080/15397734.2020.1766494

Kamarian, S., Bodaghi, M., Isfahani, R.B., Song, J.: A comparison between the effects of shape memory alloys and carbon nanotubes on the thermal buckling of laminated composite beams. Mech. Based Des. Struct. Mach. (2020). https://doi.org/10.1080/15397734.2020.1776131

Soleimanian, S., Davar, A., Eskandari Jam, J., Zamani, M.R., Heydari Beni, M.: Thermal buckling and thermal induced free vibration analysis of perforated composite plates: a mathematical model. Mech. Adv. Compos. Struct. 7, 15–23 (2020). https://doi.org/10.22075/macs.2019.16556.1181

Devarajan, B., Kapania, R.K.: Thermal buckling of curvilinearly stiffened laminated composite plates with cutouts using isogeometric analysis. Compos. Struct. 238, 111881 (2020). https://doi.org/10.1016/j.compstruct.2020.111881

Shojaee, S., Valizadeh, N., Izadpanah, E., Bui, T., Vu, T.-V.: Free vibration and buckling analysis of laminated composite plates using the NURBS-based isogeometric finite element method. Compos. Struct. 94, 1677–1693 (2012). https://doi.org/10.1016/j.compstruct.2012.01.012

Arani, A.G., Maghamikia, S., Mohammadimehr, M., Arefmanesh, A.: Buckling analysis of laminated composite rectangular plates reinforced by SWCNTs using analytical and finite element methods. J. Mech. Sci. Technol. 25, 809–820 (2011). https://doi.org/10.1007/s12206-011-0127-3

Rasid, Z.A., Ayob, A., Zahari, R., Mustapha, F., Majid, D.L., Varatharajoo, R.: Thermal buckling and post-buckling improvements of laminated composite plates using finite element method. Key Eng. Mater. 471–472, 536–541 (2011). https://doi.org/10.4028/www.scientific.net/KEM.471-472.536

Safaei, B.: Frequency-dependent damped vibrations of multifunctional foam plates sandwiched and integrated by composite faces. Eur. Phys. J. Plus. 136, 646 (2021). https://doi.org/10.1140/epjp/s13360-021-01632-4

Safaei, B.: The effect of embedding a porous core on the free vibration behavior of laminated composite plates. Steel Compos. Struct. 35, 659–670 (2020). https://doi.org/10.12989/scs.2020.35.5.641

Atilla, D., Sencan, C., Goren Kiral, B., Kiral, Z.: Free vibration and buckling analyses of laminated composite plates with cutout. Arch. Appl. Mech. 90, 2433–2448 (2020). https://doi.org/10.1007/s00419-020-01730-2

Asadi, H., Eynbeygi, M., Wang, Q.: Nonlinear thermal stability of geometrically imperfect shape memory alloy hybrid laminated composite plates. Smart Mater. Struct. 23, 075012 (2014). https://doi.org/10.1088/0964-1726/23/7/075012

Nasirmanesh, A., Mohammadi, S.: Eigenvalue buckling analysis of cracked functionally graded cylindrical shells in the framework of the extended finite element method. Compos. Struct. 159, 548–566 (2017). https://doi.org/10.1016/j.compstruct.2016.09.065

Nasirmanesh, A., Mohammadi, S.: XFEM buckling analysis of cracked composite plates. Compos. Struct. 131, 333–343 (2015). https://doi.org/10.1016/j.compstruct.2015.05.013

Xu, C., Rong, D., Zhou, Z., Deng, Z., Lim, C.W.: Vibration and buckling characteristics of cracked natural fiber reinforced composite plates with corner point-supports. Eng. Struct. 214, 110614 (2020). https://doi.org/10.1016/j.engstruct.2020.110614

Rostamijavanani, A., Ebrahimi, M.R., Jahedi, S.: Thermal post-buckling analysis of laminated composite plates embedded with shape memory alloy fibers using semi-analytical finite strip method. J. Fail. Anal. Prev. 21, 290–301 (2020). https://doi.org/10.1007/s11668-020-01068-5

Liu, Y., Qin, Z., Chu, F.: Nonlinear forced vibrations of rotating cylindrical shells under multi-harmonic excitations in thermal environment. Nonlinear Dyn. 108, 2977–2991 (2022). https://doi.org/10.1007/s11071-022-07449-9

Li, H., Siqi, Z., Shi, X., Wu, H., Zhaoye, Q., Pengxu, L., Wang, X., Zhongwei, G.: Thermal-vibration aging of fiber-reinforced polymer cylindrical shells with polyurea coating: theoretical and experimental studies. Mech. Adv. Mater. Struct. (2022). https://doi.org/10.1080/15376494.2022.2032886

Li, H., Lv, H., Gu, J., **ong, J., Han, Q., Liu, J., Qin, Z.: Nonlinear vibration characteristics of fibre reinforced composite cylindrical shells in thermal environment. Mech. Syst. Signal Process. 156, 107665 (2021). https://doi.org/10.1016/j.ymssp.2021.107665

Liu, Y., Qin, Z., Chu, F.: Nonlinear forced vibrations of functionally graded piezoelectric cylindrical shells under electric-thermo-mechanical loads. Int. J. Mech. Sci. 201, 106474 (2021). https://doi.org/10.1016/j.ijmecsci.2021.106474

Bassi, M.A., Lopez, M.A., Confalone, L., Gaudio, R.M., Lombardo, L., Lauritano, D.: Enhanced Reader.pdf (2020)

Mehar, K., Panda, S.K., Dehengia, A., Kar, V.R.: Vibration analysis of functionally graded carbon nanotube reinforced composite plate in thermal environment. J. Sandw. Struct. Mater. 18, 151–173 (2016). https://doi.org/10.1177/1099636215613324

Dewangan, H.C., Sharma, N., Hirwani, C.K., Panda, S.K.: Numerical eigenfrequency and experimental verification of variable cutout (square/rectangular) borne layered glass/epoxy flat/curved panel structure. Mech. Based Des. Struct. Mach. (2020). https://doi.org/10.1080/15397734.2020.1759432

Erukala, K.K., Mishra, P.K., Dewangan, H.C., Panda, S.K., Dwivedi, M.: Damaged composite structural strength enhancement under elevated thermal environment using shape memory alloy fiber. Acta Mech. 233, 3133–3155 (2022). https://doi.org/10.1007/s00707-022-03272-w

Cook, R.D., Malkus, D.S., Plesha, M.E., W.R.: Concepts and Applications of Finite Element Analysis. Willy, Singapore (2003)

Duan, B., Tawfik, M., Goek, S.N., Ro, J.-J., Mei, C.: Analysis and control of large thermal deflection of composite plates using shape memory alloy. Smart Struct. Mater. 2000 Ind. Commer. Appl. Smart Struct. Technol. 3991, 358–365 (2000). https://doi.org/10.1117/12.388178

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial or personal interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, E.K., Sharma, N., Panda, S.K. et al. Numerical prediction of thermal buckling load parameters of damaged polymeric layered composite structure and reversal of strength using SMA fibre. Arch Appl Mech 92, 3829–3845 (2022). https://doi.org/10.1007/s00419-022-02265-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-022-02265-4