Abstract

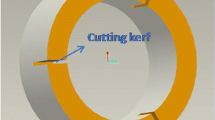

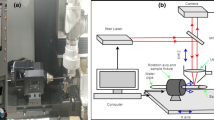

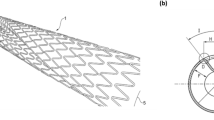

Microprofiling of medical coronary stents has been dominated by the use of Nd:YAG lasers with pulse lengths in the range of a few milliseconds, and material removal is based on the melt ejection with a high-pressure gas. As a result, recast and heat-affected zones are produced, and various post-processing procedures are required to remove these defects. This paper reports a new approach of machining stents in submerged conditions using a 100-fs pulsed laser. A comparison is given of dry and underwater femtosecond laser micromachining techniques of nickel–titanium alloy (nitinol) typically used as the material for coronary stents. The characteristics of laser interactions with the material have been studied. A femtosecond Ti:sapphire laser system (wavelength of 800 nm, pulse duration of 100 fs, repetition rate of 1 kHz) was used to perform the cutting process. It is observed that machining under a thin water film resulted in no presence of heat-affected zone, debris, spatter or recast with fine-cut surface quality. At the optimum parameters, the results obtained with dry cutting showed nearly the same cut surface quality as with cutting under water. However, debris and recast formation still appeared on the dry cut, which is based on material vaporization. Physical processes involved during the cutting process in a thin water film, i.e. bubble formation and shock waves, are discussed.

Similar content being viewed by others

References

H.Y. Zheng, A.R. Zareena, H. Huang, G.C. Lim, Mater. Sci. Forum 437–438, 277 (2003)

Y.P. Kathuria, in Int. Symp. Micromechatronics and Human Science (1998), p. 111

W. Liu, W. Du, J. Liao, Proc. SPIE 5629, 263 (2005)

A. Raval, A. Choubey, C. Engineer, D. Kothwala, Mater. Sci. Eng. A 386(1–2), 331 (2004)

K.L. Choo, Y. Ogawa, G. Kanbargi, V. Otra, L.M. Raff, R. Komanduri, Mater. Sci. Eng. A 372, 145 (2004)

A. Kruusing, Opt. Lasers Eng. 41, 307 (2004)

J.J.J. Kaakkunen, M. Silvennoinen, K. Paivasaari, P. Vahimaa, Phys. Procedia 12(Part 2), 89 (2011)

G. Daminelli, J. Krüger, W. Kautek, Thin Solid Films 467, 334 (2004)

R. An, M.D. Hoffman, M.A. Danoghue, A.J. Hunt, S.C. Jacobson, Opt. Express 16, 15206 (2008)

A. Kruusing, Opt. Lasers Eng. 41, 329 (2004)

Y. Yan, L. Li, K. Sezer, W. Wang, D. Whitehead, L. Ji, Y. Bao, Y. Jiang, J. Eur. Ceram. Soc. 31(15), 2793 (2011)

L. Li, C. Achara, CIRP Ann. Manuf. Technol. 53(1), 175 (2004)

N. Muhammad, D. Whitehead, A. Boor, L. Li, J. Mater. Process. Technol. 210(15), 2261 (2010)

H. Meng, J. Liao, Y. Zhou, Q. Zhang, Opt. Lasers Eng. 41, 300 (2009)

R.C. Smith, K.S. Baker, Appl. Opt. 20(2), 177 (1981)

E.-A. Giroux, M. Maglione, A. Gueldry, J.-L. Mantoux, J. Phys. D, Appl. Phys. 29, 923 (1996)

R. Pfeifer, D. Herzog, M. Hustedt, S. Barcikowski, J. Mater. Process. Technol. 210(14), 1918 (2010)

V. Tangwarodomnukun, J. Wang, P. Mathew, Key Eng. Mater. 443, 693 (2010)

R. Fabbro, J. Fourntier, P. Ballard, D. Devaux, J. Virmont, J. Appl. Phys. 68(2), 775 (1990)

Y. Han, C.-H. Lin, H. **ao, H.-L. Tsai, Microsyst. Technol. 15(7), 1045 (2009)

T.A. Mai, Industrial Laser Solutions (PennWell, Oklahoma, 2008)

E. Ohmura, I. Miyamoto, I. Fukumoto, Proc. SPIE 4426, 66 (2002)

D. Du, X. Liu, G. Korn, J. Squier, G. Mourou, Appl. Phys. Lett. 64, 3071 (1994)

E.-A. Brujan, A. Vogel, J. Fluid Mech. 558, 281 (2006)

E. Boulais, R. Lachaine, M. Meunier, Proc. SPIE 7925 (2011)

T. Matsumura, A. Kazama, T. Yagi, Appl. Phys. A, Mater. Sci. Process. 81(7), 1393 (2005)

D.K.Y. Low, L. Li, P.J. Byrd, J. Mater. Process. Technol. 139(1–3), 71 (2003)

Acknowledgements

The first author (N. Muhammad) acknowledges the financial support from Universiti Malaysia Perlis (UniMAP) and the Ministry of Higher Education, Malaysia for her PhD scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muhammad, N., Li, L. Underwater femtosecond laser micromachining of thin nitinol tubes for medical coronary stent manufacture. Appl. Phys. A 107, 849–861 (2012). https://doi.org/10.1007/s00339-012-6795-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-6795-8