Abstract

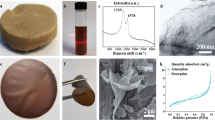

Propylation of cellulose from different sources with propionic anhydride using N-iodosuccinimide (NIS) under solvent-free condition was tested. It was done in the presence of NIS as a new catalyst for propylation using three different amounts of catalyst under mild reaction conditions. The degree of substitution by propionate was experimentally calculated and confirmed by FTIR and 1H NMR analyses. The propylation yields varied from 71.54 to 88.37% with the degree of substitution (DS) ranged from 1.32 to 2.80 for commercial cotton cellulose, 1.76–3.00 for rice husk cellulose, and 1.60–3.0 for wheat straw cellulose. The DS were easily controlled by changing the reaction duration (2–6 h) and the amount of the NIS catalyst (50, 75, and 100 mg for each 1.0 g of cellulose) in 25 mL of propionic anhydride. Prolonging the reaction’s duration has no favorable effect on the propylation process and led to decrease in the cellulose propionate (CP). Also, increasing the amount of NIS catalyst results in decrease the DS and CP yield. NIS was recognized as a novel and more successful catalyst for propylation of the hydroxyl groups of cellulose from different sources in high degree of substitution.

Similar content being viewed by others

References

Young RA (2002) Cross-linked cellulose and cellulose derivatives. In: Chattcrjee PK, Gupta BS (eds) Absorbent technology. Elsevier Science B.V., Amsterdam, pp 233–281

El Nemr A (ed) (2012) Textiles: types, uses and production methods. Nova Science Publishers, Inc. Hauppauge. Hard cover [ISBN: 978-1-62100-239-0], e-book [ISBN: 978-1-62100-284-0] 621p

Moshiul Alam AKM, Beg MDH, Reddy Prasad DM, Khan MR, Mina MF (2012) Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly(lactic acid) composites. Compos A 43:1921–1929. https://doi.org/10.1016/j.compositesa.2012.06.012

Yamaguchi M, Masuzaw K (2007) Birefringence control for binary blends of cellulose acetate propionate and poly(vinyl acetate). Eur Polym J 43:3277–3282

El Nemr A, Ragab S, El Sikaily A, Khaled A (2015) Synthesis of cellulose triacetate from cotton cellulose by using NIS as a catalyst under mild reaction conditions. Carbohyd Polym 130:41–48

El Nemr A, Ragab S, El Sikaily A (2016) Testing zinc chloride as a new catalyst for direct synthesis of cellulose di- and tri-acetate in a solvent free system under microwave irradiation. Carbohydr Polym 151:1058–1067. https://doi.org/10.1016/j.carbpol.2016.06.072

El Nemr A, Ragab S, El Sikaily A (2017) Rapid synthesis of cellulose triacetate from cotton cellulose and its effect on specific surface area and particle size distribution. Iran Polym J 26(4):261–272. https://doi.org/10.1007/s13726-017-0516-2

Ragab S, El Nemr A (2018) Nanofiber cellulose di- and tri-acetate using ferric chloride as a catalyst promoting highly efficient synthesis under microwave irradiation. J Macromol Sci A Pure Appl Chem 55(2):124–134. https://doi.org/10.1080/10601325.2017.1387741

El Nemr A, Ragab S (2018) Acetylation of Cotton-Giza 86 cellulose using MnCl2 as a new catalyst and its application to machine oil removal. Environ Process 5(4):895–905. https://doi.org/10.1007/s40710-018-0330-7

Malucelli LC, Lomonaco D, Filho MASC, Magalhães WLE (2019) Cellulose triacetate from different sources: modification assessment through thermal and chemical characterization. Holzforschung. https://doi.org/10.1515/hf-2019-0035

Ragab S, El Nemr A (2019) Zirconyl chloride as a novel and efficient green Lewis acid catalyst for direct acetylation of cotton cellulose in the presence and absence of solvent. J Polym Res 26:156. https://doi.org/10.1007/s10965-019-1816-3

Cheng HN, Dowd MK, Shogren RL, Biswas A (2011) Conversion of cotton byproducts to mixed cellulose esters. Carbohyd Polym 86:1130–1136

Hummel A (2004) 3.2 Industrial processes. Macromol Symp 208:61–80. https://doi.org/10.1002/masy.200450406

Bianchi E, Marsano E, Ricco L, Conio G (1997) Derivatization of cellulose in homogeneous condition: 1-cellulose propionate. Carbohyd Polym 34:91–94

Heinze T, Dorn S, Schöbitz M, Liebert T, Köhler S, Meister F (2008) Interactions of ionic liquids with polysaccharides—2. Cellulose. Macromol Symp 262(1):8–22

Luana Y, Zhang J, Zhan M, Wu J, Zhang J, He J (2013) Highly efficient propionylation and butyralation of cellulose in an ionic liquid catalyzed by 4-dimethylminopyridine. Carbohyd Polym 92(2013):307–311

Cao X, Peng X, Zhong L, Sun S, Yang D, Zhang X, Sun R (2014) A novel trans-esterification system to rapidly synthesize cellulose aliphatic esters. Cellulose 21:581–594

Ass BAP, Ciacco GT, Frollini E (2006) Cellulose acetates from linters and sisal: correlation between synthesis conditions in DMAc/LiCl and product properties. Biores Technol 97(14):1696–1702

Elomaa M, Asplund T, Soininen P, Laatikainen R, Peltonen S, Hyvarinen S et al (2004) Determination of the degree of substitution of acetylated starch by hydrolysis, H-1 NMR and TGA/IR. Carbohyd Polym 57(3):261–267

Sun XW, Lu CH, Zhang W, Tian D, Zhang XX (2013) Acetone-soluble cellulose acetate extracted from waste blended fabrics via ionic liquid catalyzed acetylation. Carbohyd Polym 98(1):405–411

Das AM, Ali AA, Hazarika MP (2014) Synthesis and characterization of cellulose acetate from rice husk: eco-friendly condition. Carbohyd Polym 112(2014):342–349

Liu R, Yu H, Huang Y (2005) Structure and morphology of cellulose in wheat straw. Cellulose 12(2005):25–34. https://doi.org/10.1007/s10570-004-0955-8

Li J, Zhang LP, Peng F, Bian J, Yuan TQ, Xu F et al (2009) Microwave-assisted solvent-free acetylation of cellulose with acetic anhydride in the presence of iodine as a catalyst. Molecules 14:3551–3566

Buchanan CM, Hyatt JA, Lowman DW (1987) Two-dimensional NMR of polysaccharides: spectral assignments of cellulose triesters. Macromolecules 20:2750–2754

Kowsaka K, Okajima K, Kamide K (1988) Two-dimensional magnetic resonance spectra of cellulose and cellulose triacetate. Polym J 20:1091–1099

Shuto Y, Murayama M, Azuma J, Okamura K (1988) NMR assignments of propionyl groups in cellulose tripropionate. Bull Inst Chem Res Kyoto Univ 66:128–135

Bijarimi M, Ahmad S, Alam AKMM (2017) Toughening effect of liquid natural rubber on the morphology and thermo-mechanical properties of the poly(lactic acid) ternary blend. Polym Bull 74:3301–3317. https://doi.org/10.1007/s00289-016-1889-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El Nemr, A., Eleryan, A., Mashaly, M. et al. Comparative study of synthesis of cellulose propionate from different sources using NIS as a new catalyst. Polym. Bull. 78, 4369–4386 (2021). https://doi.org/10.1007/s00289-020-03313-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03313-1